9 Diagnistics

20

ESR5-NV3-30

12/19 MN049010EN

www.eaton.com

9 Diagnistics

○

– LED o

ff

●

– LED

fl

ashes

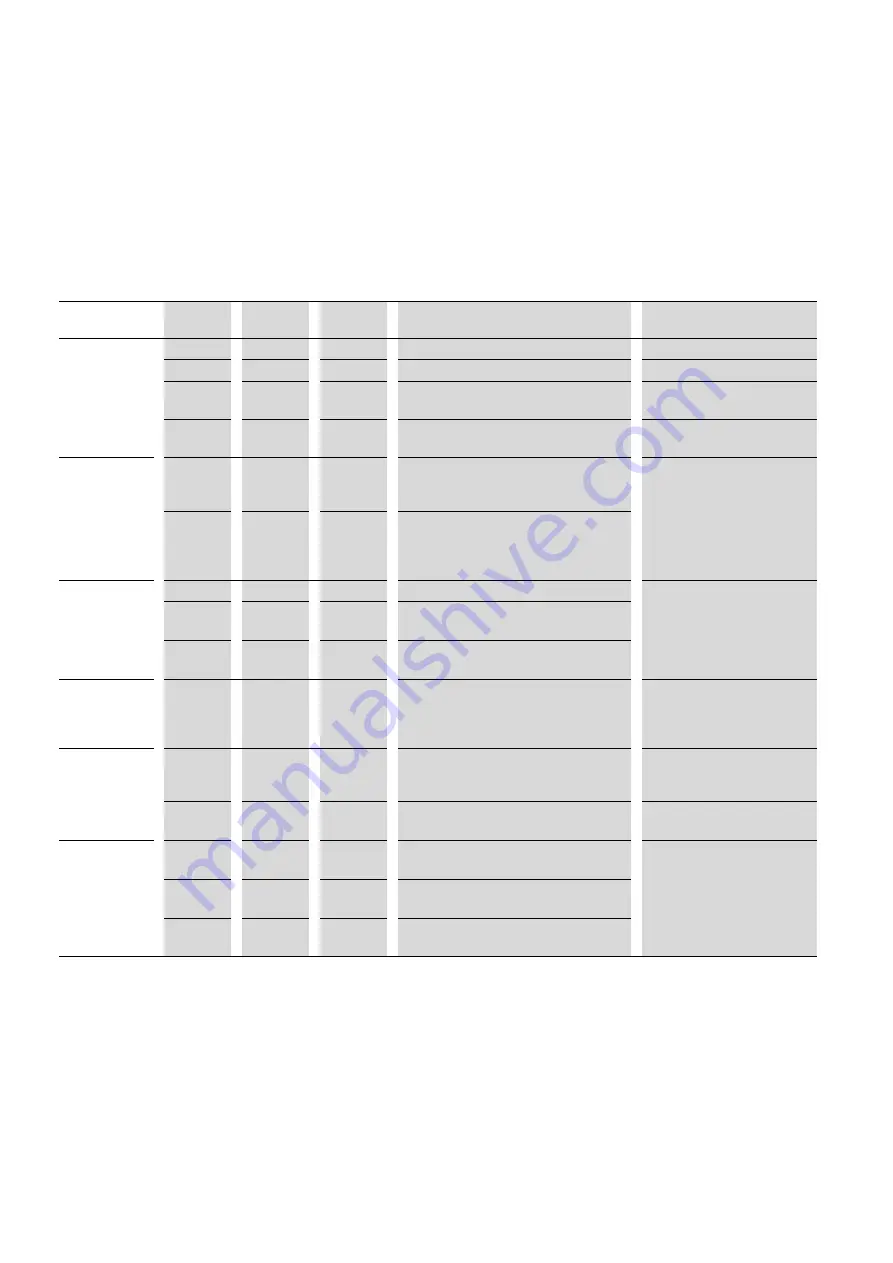

Table 1: Diagnostic description

Power

K1/K2

K3(t)/K4(t)

Fault

Remedy

Connection/

voltage error

○

○

○

Supply voltage not present.

Apply supply voltage.

★

○

○

Supply voltage too low.

Adjust supply voltage.

★

1 s

○

○

Supply voltage too high.

Adjust supply voltage.

★

○

○

The enable circuits are connected incorrectly

or not connected at all.

Check the connection of the

enable circuits.

Cross-circuit

★

1 s

○

○

Between both enable circuits S11-S12 and

S21-S22.

E.g., for emergency stop or safety door.

Remove cross-circuit.

★

○

○

Between enable circuit S12-S22 for applica-

tions with light grid and safe PLC.

Fault is detected and indicated by the light grid/

PLC.

Short circuit

○

○

○

Between contact points A1 and A2.

Remove short circuit.

★

1 s

○

○

Between S11 and S12.

Error detection on next demand.

★

1 s

○

○

Between S21 and S22.

Fault detection on next demand.

Fault in reset

circuit

★

1 s

○

○

Faulty reset button.

Short circuit between A1 and S34.

No fault detection on initial start, only once all

enable contacts have been opened.

Remove short circuit.

Configuration

error

★

1 s

★

1 s

○

If a cross-circuit or overvoltage/undervoltage

occurs during the configuration phase, the

safety module indicates a configuration error.

Check the wiring and the operat-

ing voltage supply.

Perform a voltage reset.

★

1 s

★

1 s

★

1 s

Rotary switch (delay time) was modi- fied.

Perform configuration again.

Fault with

internal cause

★

0,2 s

○

○

Safety relay faulty.

Replace safety relays. Perform a

voltage reset.

★

0,2 s

○

○

Enable contact(s) of K1 and K2 faulty.

★

0,2 s

○

○

Enable contact(s) of K3 and K4 faulty.

Summary of Contents for ESR5-NV3-30

Page 1: ...Manual ESR5 NV3 30 Safety relay 12 19 MN049010EN...

Page 4: ......