Diesel Engine Fire Pump Controller

EATON CORPORATION

www.ceaton.com

15

6.3 Controller Diagnostics

The Diesel Plus controller has a number of diagnostic points

that can be used to help in troubleshooting issues with the

controller. The diagnostics can be viewed on the main display,

saved to a USB storage device, or viewed on the optional

embedded webpage.

In order to view the diagnostics on the display press the up or

down arrow buttons from the main screen until the display

shows “Controller Diagnostics”. Press the Ack. Alarm button to

view the diagnostics. The display will show the diagnostics. In

order to navigate the diagnostics use the up or down arrow

buttons.

NOTE

The diagnostic information shall be provided to personnel trained in the

meaning of the values shown.

Diagnostic values that are recorded are the current date and

time, the microprocessor’s firmware version, Eaton’s shop

order number, customer order number, voltage readings,

pressure sensor readings, input status, and relay status.

Refer to Section 7 to save the controller diagnostics to a USB

storage device or to view the message history on the optional

embedded webpage.

7. COMMUNICATION

The Diesel Plus controller is available with a number of optional

communication protocols that can be used for the collection of

information.

Communication protocols include USB (standard), Ethernet and

RS485 (both optional).

7.1 USB

The USB port is used to download the controller message

history, statistics, diagnostics, status and configuration data to

a USB storage device. The USB port can also be used to upload

custom messages, additional languages, and update the

microprocessor firmware.

7.1.1 Information Download

• In order to download the history, diagnostics, statistics,

status and configuration - install a USB storage device into

the USB port on the display board. With the power on, press

the Data | Print button. The first selection is “Save to USB”.

Press the Ack. Alarm button and the controller will save the

information to the USB storage device.

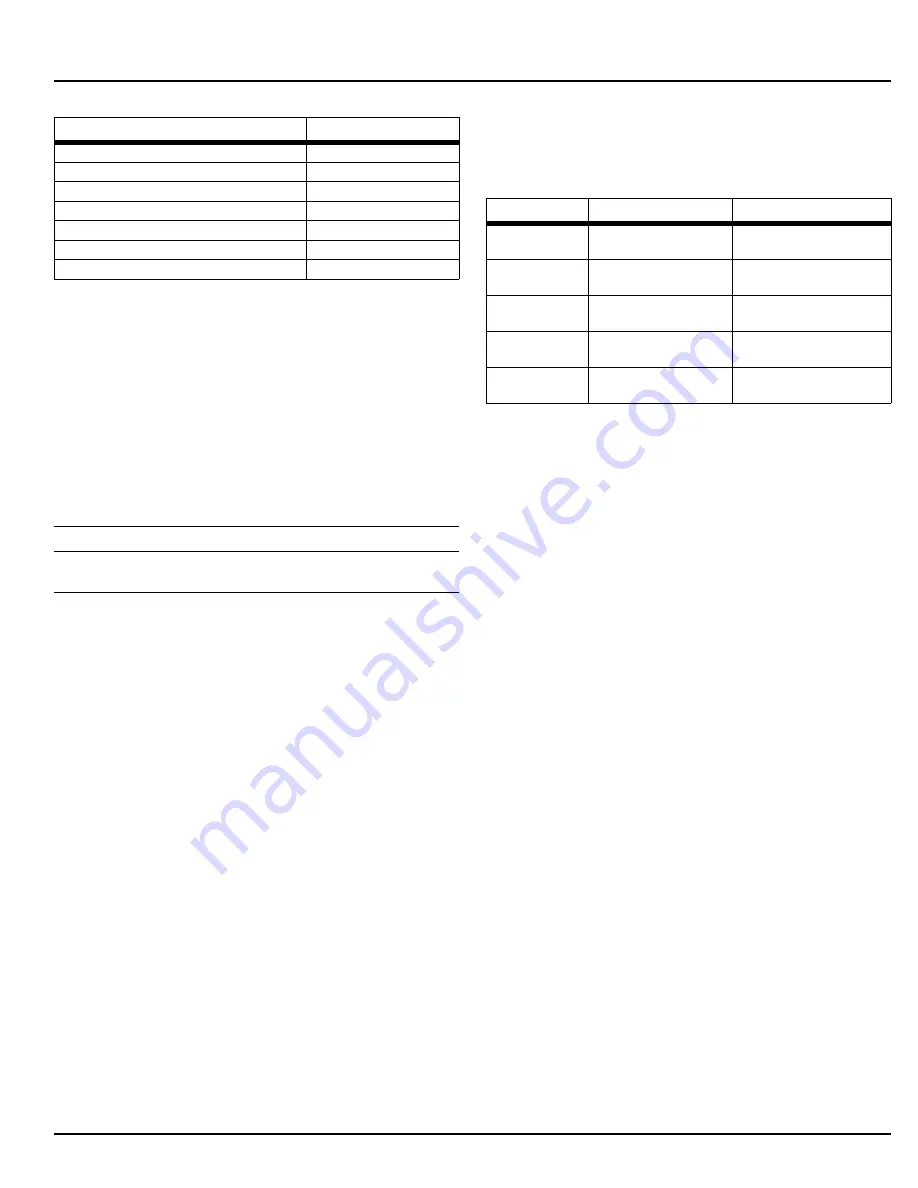

• There will be five (5) files saved to the storage device. Refer to

Table 6 for the file nomenclature.

• The .csv file is a comma separated values file that can be

opened using standard spreadsheet, word processor, or

database programs. The .txt files can be opened using

standard text viewers.

7.1.2 Custom Message Upload

• The Diesel Plus controller has the ability to store and use up

to ten (10) custom messages that can appear based on a

specific date, time, alarm or status condition.

• Refer to Appendix H to upload and enable the custom

messages.

• Refer to Section 8 for the creation of the custom message file.

7.1.3 Firmware Update

• Contact the factory or an authorized trained representative for

assistance.

7.1.4 Language Upload

• Contact the factory or an authorized trained representative for

assistance.

7.2 Embedded Webpage (Optional)

The controller is available with an optional webpage that can be

used to view the main display of the controller and its current

status.

Contact the factory or an authorized trained representative for

assistance in accessing the webpage.

7.3 RS485 Serial Port (Optional)

Contact the factory or an authorized trained representative for

assistance.

7.4 RS232 Serial Port (Optional)

This port is used with the optional printer (X1) to initiate a print

cycle.

Last High Engine Temp.

Date & Time

Last Overspeed

Date & Time

Last Fail To Start

Date & Time

Last Low Fuel

Date & Time

Last Charger Failure

Date & Time

Last Battery Failure

Date & Time

Last ECM Alarm

Date & Time

Table 5. Controller Statistics (Continued)

Statistic

Range

Table 6. File Nomenclature

File

Nomenclature

Description

ARC00000.csv

ARC=Archive

00000=Serial number

Message history

STC00000.txt

STC=Statistics

00000=Serial number

Controller statistics

DIA00000.txt

DIA=Diagnostics

00000=Serial number

Controller diagnostics

STA00000.txt

STA=Statistics

00000=Serial number

Controller status

CON00000.txt

CON=Configuration

00000=Serial number

Controller configuration