3 Installation

3.5 EMC installation

DC1-S…20…, DC1-S…OE1 Variable Frequency Drives

05/21 MN040058EN

www.eaton.com

55

3.5 EMC installation

The responsibility to comply with the legally stipulated limit values and thus

the provision of electromagnetic compatibility is the responsibility of the end

user or system operator. This operator must also take measures to minimize

or remove emission in the environment concerned. He must also utilize

means to increase the interference immunity of the devices of the system.

The technology and system of a variable frequency drive cause the flow of

high frequency leakage current during operation. Because of this, all earthing

elements must be low-impedance elements connected in such a way as to

establish an electrical contact across a large surface area.

With leakage currents greater than 3.5 mA, in accordance with

IEC/EN 61800-5-1 or EN 60335, either

•

the cable cross-section of the protective conductor must be

≧

10 mm

2

,

•

the protective conductor must be open-circuit monitored, or

•

the second protective conductor must be fitted.

For an EMC-compliant installation, we recommend the following measures:

•

installation of the variable frequency drive in a metallically conductive

housing with a good connection to ground,

•

screened motor cables (short cables).

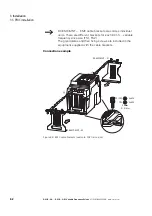

3.5.1 EMC measures in the control panel

In order to have an installation that meets EMC requirements, make sure to

connect all the metallic parts in the devices and in the control panel to each

other across a large area and in a way that will make it possible to conduct

high frequencies. Mounting plates and control panel doors should be

connected to the panel by means of short drain wires with an electrical

contact established across a large surface area.

→

In a magnet system (PDS) with variable frequency drives, you

should take measures for electromagnetic compatibility (EMC)

while doing your engineering, since changes or improvements

to the installation site, which are required in the installation or

while mounting, are normally associated with additional higher

costs as well.

→

Ground all conductive components and housings in a drive

system using as short a line as possible with the greatest

possible cross-section (Cu-braid).

→

Do not make connections to painted surfaces (electrolytic

oxidation, yellow chromated).

→

Install the variable frequency drive as directly as possible

(without spacers) on a metal plate (mounting plate).

Summary of Contents for DC1-S1011NB-A20CE1 1

Page 4: ......