Form C-1519

3

MAINTENANCE PROCEDURES

1. Be sure the baseplate rollers are kept lint free.

2. Be sure the terminal pins on the terminal block are in

good condition to make full contact with the female

receptacle.

3. Inspect the operating switch periodically for full contact

when in the ON position.

4. When replacing the knife on this cutting unit, remove

any lint build-up between the knife and the standard.

5. If the cutting unit seems to lag while not cutting, the knife

should be removed and the unit should be run without

the knife to see if the machine has been overgreased

or if there is an obstruction somewhere.

OPTIONAL

The RS2 Rubber Slitter has been designed for quick and

easy conversion between the standard Baseplate and the

optional Strip Gauge. To make the conversion; disconnect

the power attachment plug. Remove (5) screws, (308C15-

2) and (308C15-3) between the bracket and standard. The

new strip gauge can now be mounted using the same (5)

screws and ready for use in minutes as shown on page 18.

Strip gauge operation is identical to that of the standard

Baseplate with the added advantage of a Strip Gauge for

cutting strips up to 11" wide and

1 1/2" thick.

KNIFE SHARPENING

Take the machine out of material to be cut. Switch machine

to ON position, note setting of variable speed and increase

speed to full capacity. To obtain a fine, keen edge on blade,

press lightly on sharpener lever with a constant pressure.

Hold lever until blade is sharp, then release. Return vari-

able speed setting to cutting speed.

TO REPLACE THE KNIFE

Loosen thumb screw and slide guard to upward position.

Turn the knife so the small hole lines up with hole in the

standard and insert knife removal pin (17C11) into hole.

Loosen three (3) setscrews in the locknut and remove the

locknut that retains the blade with the special spanner

wrench (95C1-13). When installing a new knife, be sure

the name Eastman Machine Company is facing outward

and the knife seats on the knife gear. Install knife locknut

and secure setscrews. Secure guard in operating position.

Refer to page 13 for replacement knives.

CAUTION:

Discard used sharp knives with care.

CAUTION

Do not use sewing machine oil or detergent oil. It is

entirely too light for cutting machine lubrication. For

best results use specially compounded Eastman Oil.

Do not oil Base Plate Rollers.

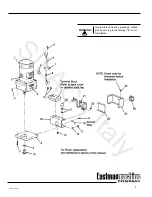

ITEM PART NO. DESCRIPTION

QTY.

WARNING

Before performing any of the following procedures,

make sure that the attachment plug has been discon-

nected from power source.

1

See Page 11

Knives

1

2

95C1-13

Spanner Wrench

1

3

17C11

Knife Removal Pin

1

4

See Page 12

Emery Wheels

1

5

242C1

Eastman Oil

1

6

242C2

Eastman Gear Lubricant

1

7

242C2-2

Eastman Lubriko

Bearing Grease

1

8

See Page 15

Plastic Master Fluid

1

Maintenance Supplies

SILAC

- Italy