14 Installation

Installation

Lift the machine up and off of the shipping pallet.

CAUTION!

The VSA series L-sealer is heavy and will require a forklift,

floor crane, or several people to move safely off the shipping

pallet. Use proper equipment when lifting the L-sealer and

ensure it is secure and will not shift while being moved off

the shipping pallet.

Place the sealer in the desired location with the required electrical power source

available. (See power requirements for the specific model in the Specifications table.)

Make sure the electrical wiring is adequate to provide the required voltage. If the voltage

provided is too low, the equipment will not operate correctly.

Selecting the proper location is one of the most important considerations for initial

setup. When selecting the location, take into consideration the following factors.

1. Adequate power supply nearby?

2. Where is the sealer in relation to the power source?

3. Where is the sealer in relation to the tunnel and any conveyor(s) necessary to

move the wrapped product? (Alignment with packaging line.)

4. Convenience for the operator.

If there is any doubt, get qualified assistance with your initial installation.

Location Requirements

When installing the L-sealer please be aware of the following considerations:

1. The surface on which it is located is flat and level.

2. Conveyor or packing table height.

3. Alignment with packaging line.

When the L-sealer is positioned in the operating location you will need access to:

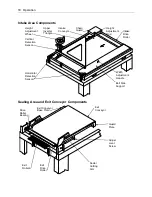

1. Control panel switches: On/Off switch, dwell timer, conveyor timer.

2. Height and width adjustments.

3. Film unwinder.

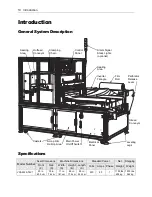

Summary of Contents for Value VSA2530TK-V1

Page 1: ...VSA Value Series Auto L Sealers User Guide VSA2530TK V1 ...

Page 2: ......

Page 4: ......

Page 73: ...Appendix A Electrical Schematic 73 VSA2530 TKV1 Sheet 2 of 5 ...

Page 74: ...74 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 3 of 5 ...

Page 75: ...Appendix A Electrical Schematic 75 VSA2530 TKV1 Sheet 4 of 5 ...

Page 76: ...76 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 5 of 5 ...

Page 78: ...78 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 2 of 6 ...

Page 79: ...Appendix A Electrical Schematic 79 VSA2530 TKV2 Sheet 3 of 6 ...

Page 80: ...80 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 4 of 6 ...

Page 81: ...Appendix A Electrical Schematic 81 VSA2530 TKV2 Sheet 5 of 6 ...

Page 82: ...82 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 6 of 6 ...

Page 83: ...Appendix B Air Diagram Pneumatic Schematic 83 Appendix B Air Diagram Pneumatic Schematic ...

Page 88: ......