21

Belt Modulus Factors (Mf)

Table 3-4

Belt Type

Modulus

Factor

Belt Type

Modulus

Factor

A

0.500

E

5.938

B

0.813

3V

0.375

C

2.500

5V

0.750

D

5.000

8V

1.563

Pf = Position factor, a factor used to correct overhung load

capacity when the center of belt pull is not on the

center of the shaft keyway extension. Location

"L" is on the center of keyway. See Table 3-4

and Figure 3-1.

Mf = Belt Modulus Factor from Table 3-5.

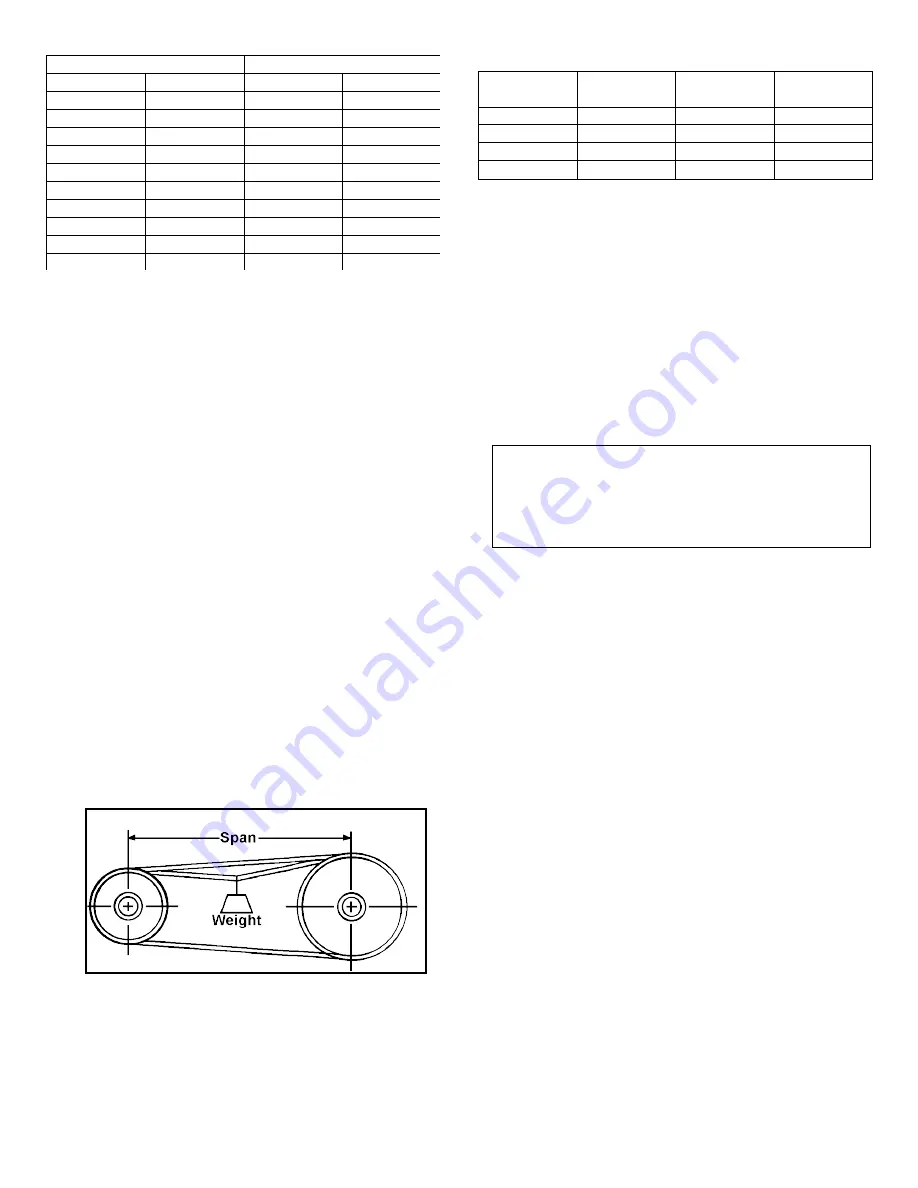

2. Apply deflection pressure by hanging a weight on

each belt at the midpoint of the span as shown in

Figure 3-7. Pressure can also be applied using a

small spring scale. When properly adjusted, each belt

should deflect "1/64" for each inch of span.

3. If belts slip after tension has been properly adjusted,

sheaves or belts have been improperly sized.

4. With new belts, tensions should be checked and

adjusted after each 24 hours of operation until belts

are broken in.

Final Mounting

After completing the initial mounting procedures and

necessary alignment, secure the unit as follows:

1. Make sure unit is level and its feet are still in contact

with the mounting pads. If several thin shims were

installed during alignment, consider replacing them

with thicker shims. A few thick shims are preferred to

many thin ones.

2. Tighten mounting bolts or nuts to secure unit to base.

Recheck alignment and, if necessary, correct it.

Tightening bolts may pull unit down, especially when

many shims are used.

Precision Tension Check

Figure 3-6

3. For directly coupled units, dowel all interconnected

units to base to ensure that shaft alignment will be

maintained. For belt coupled units, recheck belt

tension arid correct it if necessary. Tightening bolts or

nuts may have moved unit, causing over- tensioning,

even though tension was proper before bolts were

tightened.

Lubrication

Bearings are grease lubricated and require no special

attention unless stored for over one year. Consult the

sections on "Storage" and/or "Maintenance" for greasing

instructions.

Shaft and Belt Guards

Before applying power and starting the unit, install guards

over all rotating shafts, couplings, belts and chain

devices. Refer to OSHA rules and regulation, paragraph

1910.219 for requirements covering guards on

mechanical power transmission apparatus. Be sure

machine is safe to operate and all safety devices have

been installed, checked out and made operable.

CAUTION

: When designing belt and shaft guards,

remember that bearings must be lubricated

periodically. Grease fittings should be accessible

through openings in guards and signs should indicate

the exact location of each grease inlet and outlet.

Electrical Wiring

All wiring to the drive, including any accessories, must

conform to the National Electrical Code and all other

applicable state and local codes. Motor leads and

transformer winding leads are terminated in a conduit box

mounted on the side of the motor. Leads for the clutch and

tachometer generator are terminated in a conduit box

mounted on the clutch housing. Accessories may also be

wired to the same conduit box or may be terminated in

another conduit box attached to the accessory.

Connections from the conduit boxes to the controller are

made by connecting each lead or terminal to the

appropriate lead or terminal in the controller as shown on

the connection diagram furnished with the controller.

Figure 3-8 shows typical connections for a standard drive

without any modifications or accessories. Section 8 of this

manual includes typical connection diagrams for common

accessories. For specially modified drives, refer to the

instructions furnished for the modification or added

accessory and to the instructions and diagrams furnished

with the controller. Tachometer generator leads and

speed signal reference leads should not be run in the

same conduit with motor power leads.

Transformer Winding (Applies to Models DCD-132

through DCD-225 ONLY)

The motor furnished with the drive DO NOT INCLUDE a

single phase, 115-volt, center tapped transformer winding

that can be used as a power source for the external

controller. The controllers requires a separate power

source.

Span

“Y” Dimension

Inches

mm

Inches

mm

60

1525

2.50

63

80

2030

2.75

70

100

2540

3.00

76

120

3050

4.00

101

140

3560

5.25

133

160

4060

6.50

165

180

4570

7.75

200

200

5080

9.00

230

220

5590

10.50

270

240

6100

12.00

305