11

4.3.4.

Mounting the water cover

1)

Take the water cover with the gasket and the

mounting materials out of the wooden case (see

the lifting instructions of section 3.2).

2)

Inspect the water cover before installation,

especially the coating. Touch up when necessary.

3)

Clean the gasket faces and make sure they are

free of defects (burrs, pits, dents, etc.).

4)

Position the supplied gasket between the water

cover and the tube bundle (item 2 of fig. 7). Make

sure the partitioning corresponds with the

drawing and the water cover.

Make sure the gasket is clean.

Do not use glue, sealant, grease or any other

sealing agent when installing the SBR gasket.

5)

Carefully put the water cover in place. Check the

orientation, refer to the supplied drawing.

Mind the weight. Take care not to damage the

coatings, the gasket or the gasket faces.

6)

Position the supplied bolts and the nuts for the

collar bolts in the bolt holes and fasten hand tight

(see fig. 8a and 8b).

7)

Tighten all bolts and nuts alternate and crosswise

with a torque wrench to guarantee an even

setting of the gaskets.

Refer to section 4.4.4 for tightening torques.

The water cover can be painted on the outside.

Do not paint the inside of the water box.

The paint may

be stripped off by the fluid and blind the tubes.

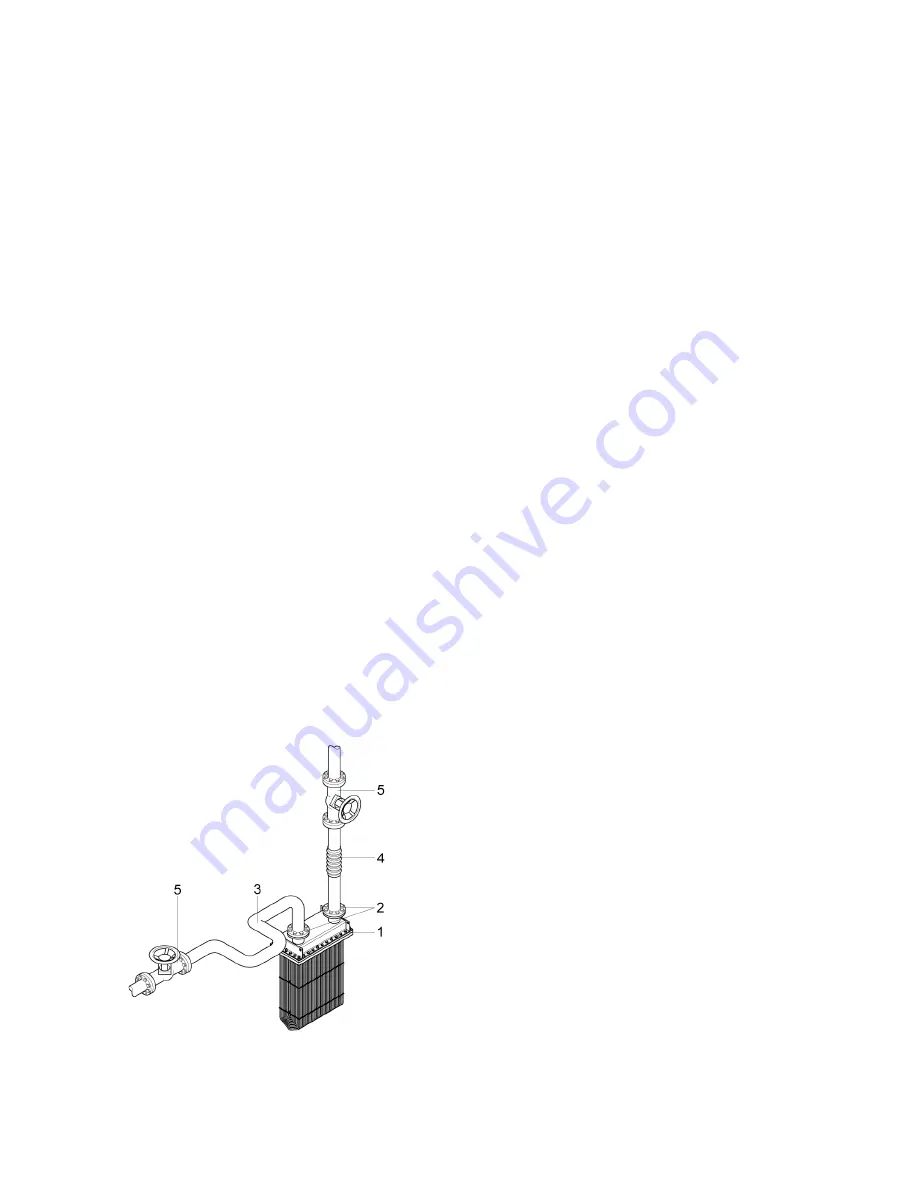

Figure 11. Typical piping installation with an expansion

loop (3), an expansion joint (4) and service valves (5),

connected to the box cooler flanges (1 and 2).

4.4.

FIXING THE PROCESS PIPING

Ensure that all piping will be fixed to the box cooler

without transferring load and (piping) vibrations to

the box cooler.

Install safety devices to prevent overpressure and

overheating (see section 4.4.2).

4.4.1.

Piping design

§

Ensure that the piping is well supported,

independently from the box cooler

and secured as close to the box cooler as possible.

§

Avoid transferring piping vibrations to the heat

exchanger. When needed, fit compensators which

can absorb piping vibrations.

§

Make sure the piping system allow for thermal

expansion and contraction of both the box cooler

and the attached piping. Ensure adequate

flexibility of the piping system (e.g. by fitting

expansion loops and expansion joints, see fig. 11).

Pipe supports should also allow for pipe

movement.

§

Prevent piping misalignment. This will cause

increased nozzle loads. Note that the mentioned

compensators and expansion joints also help to

absorb some piping misalignment.

§

Install adequate means for safe and complete

draining and venting of the box cooler.

Fit air vents at high points to allow for system

bleeding. System bleeding is required to ensure

optimal heat transfer and to prevent fluid

hammer. Venting is also required to enable

complete drainage of the box cooler.

Draining is required to permit safe maintenance

and, when applicable, to prevent freezing during

shutdown periods (see section 5.3).

§

Install manual service valves or bypasses in the

supply and return pipes to enable isolation of the

box cooler from the supply piping. In this way safe

inspection and maintenance can be carried out

without having to shut down or drain a larger

system (see fig. 11).

§

Install -‐ when required -‐ measuring devices to

monitor the pressure, temperature and/or flow

during operation. Fix the devices close to the box

cooler to measure accurately.