Fault Finding

95

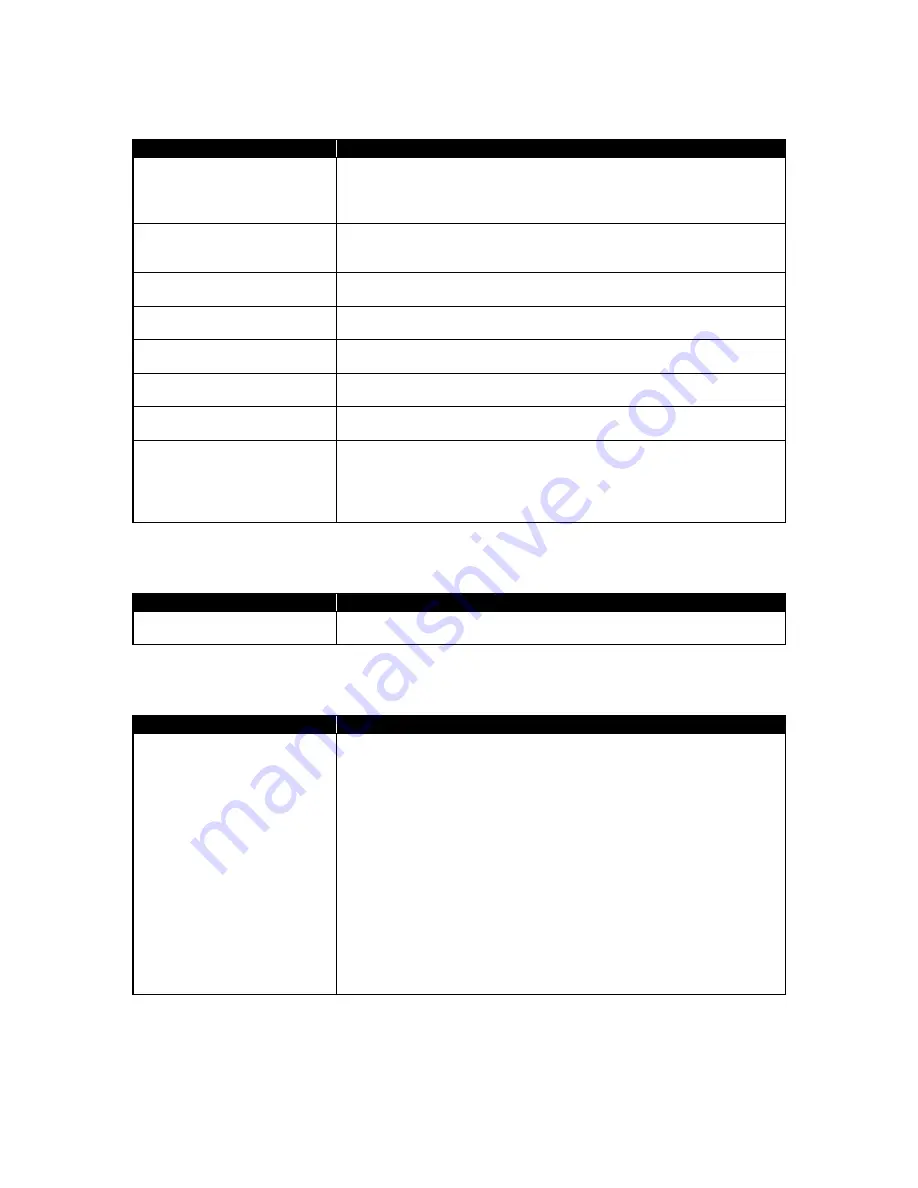

9.3 ALARMS

Symptom

Possible Remedy

Low oil Pressure fault

operates after engine has

fired

Check engine oil pressure. Check oil pressure switch/sensor and

wiring. Check configured polarity (if applicable) is correct (i.e.

Normally Open or Normally Closed) or that sensor is compatible with

the module and is correctly configured.

High engine temperature fault

operates after engine has

fired.

Check engine temperature. Check switch/sensor and wiring. Check

configured polarity (if applicable) is correct (i.e. Normally Open or

Normally Closed) or that sensor is compatible with the module.

Shutdown fault operates

Check relevant switch and wiring of fault indicated on LCD display.

Check configuration of input.

Electrical Trip fault operates

Check relevant switch and wiring of fault indicated on LCD display.

Check configuration of input.

Warning fault operates

Check relevant switch and wiring of fault indicated on LCD display.

Check configuration of input.

CAN ECU WARNING

CAN ECU SHUTDOWN

This indicates a fault condition detected by the engine ECU and

transmitted to the DSE controller.

CAN DATA FAIL

Indicates failure of the CAN data link to the engine ECU.

Check all wiring and termination resistors (if required).

Incorrect reading on Engine

gauges

Fail to stop alarm when

engine is at rest

Check engine is operating correctly. Check sensor and wiring paying

particular attention to the wiring to terminal 10 (refer to appendix).

Check that sensor is compatible with the module and that the

module configuration is suited to the sensor.

9.4 COMMUNICATIONS

Symptom

Possible Remedy

CAN DATA FAIL

Indicates failure of the CAN data link to the engine ECU.

Check all wiring and termination resistors (if required).

9.5 INSTRUMENTS

Symptom

Possible Remedy

Inaccurate generator

measurements on controller

display

Check that the CT primary, CT secondary and VT ratio settings are

correct for the application.

Check that the CTs are wired correctly with regards to the direction

of current flow (p1,p2 and s1,s2) and additionally ensure that CTs

are connected to the correct phase (errors occur if CT1 is connected

to phase 2).

Remember to consider the power factor (kW = kVA x powerfactor).

The controller is true RMS measuring so gives more accurate

display when compared with an ‘averaging’ meter such as an

analogue panel meter or some lower specified digital multimeters.

Accuracy of the controller is better than 1% of full scale. Generator

voltage full scale is 415V ph-N, accuracy is ±4.15V (1% of 415V).

Summary of Contents for DSE7110 MKII

Page 34: ...Installation 34 4 2 1 DSE7110 MKII TYPICAL WIRING DIAGRAM 3 PHASE 4 WIRE ...

Page 35: ...Installation 35 4 2 2 DSE7120 MKII TYPICAL WIRING DIAGRAM 3 PHASE 4 WIRE ...

Page 36: ...Installation 36 4 3 ALTERNATE TOPOLOGY WIRING DIAGRAMS 4 3 1 GENERATOR ...

Page 37: ...Installation 37 4 3 2 MAINS DSE7120 MKII ONLY ...