6

7.4.

USE

•

Check the setting data indicated on the control panel (if present).

•

Press the start button on the machine where the pump is connected.

•

Ensure that the pump starts.

•

Ensure the adequate lubrication of the machine (if there are doubts on correct operation, you can contact the Dropsa

S.p.A. Technical Office and ask for the testing procedure).

8.

PROBLEMS AND SOLUTIONS

Below is a troubleshooting table where the main faults, probable causes and possible solutions to be carried out immediately

are indicated (contact Dropsa).

In the event of doubts and/or irresolvable problems, do not search for the fault disassembling parts of the pump, but rather

contact the Dropsa Technical Office.

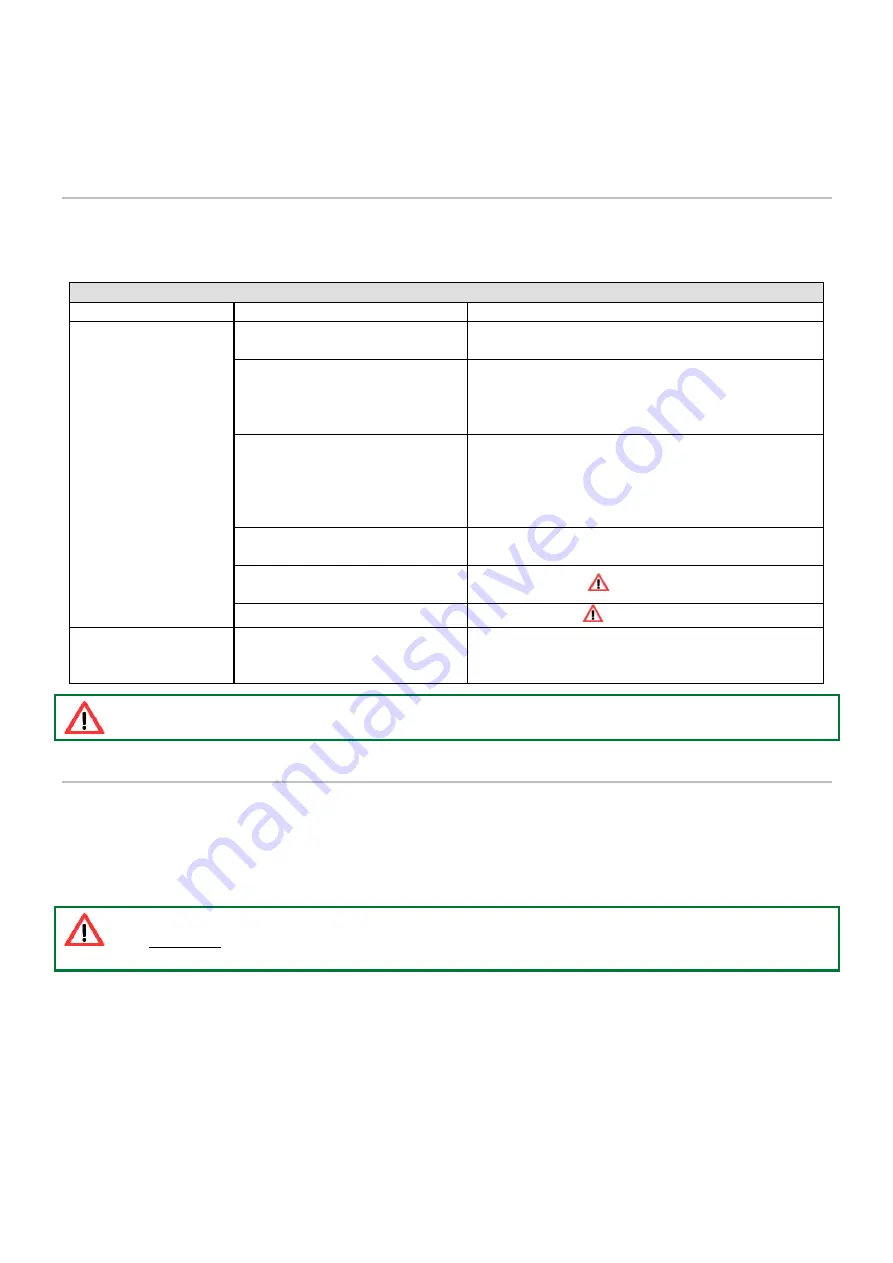

TROUBLESHOOTING TABLE

FAULT

CAUSE

REMEDIAL ACTION TO BE TAKEN

The pump does not

dispense lubricant or

does not dispense the

prescribed quantity.

The lubricant in the reservoir is

below the minimum level.

Top up the reservoir without exceeding the MAX level line.

The pump control solenoid valve

does not vent.

Ensure that the pump control solenoid valve is a 3-way

valve for single acting pumps or 4-way for dual acting

pumps. Also ensure that the oil in the pump chamber

discharges regularly.

Air bubbles in the lubricant.

Open the bleed valve and activate the pump according to

the manual operating cycle until lubricant comes out of

the connection without any air bubbles. Close the valve.

You can manually press the cartridge itself in order to

favour priming of the pumping unit.

The fittings are loose.

Carefully tighten all the fittings, ensuring that there are

no leaks.

The piston of the pumping element

is worn out.

Replace the piston

.

The delivery valve is blocked.

Replace the valve

.

The pump does not

dispense lubricant at the

prescribed pressure.

The pressure regulation of the

incoming control oil is incorrect.

Appropriately regulate the oil pressure as prescribed by

the general characteristics and bearing in mind the

compression ratio.

Operation may only be carried out by Dropsa specialised personnel.

9.

MAINTENANCE PROCEDURES

The pump does not require special tools for any check and/or maintenance operations. In any case, it is recommended to use suitable

equipment and personal protective equipment (gloves, protection goggles, etc.) that in good condition in accordance with applicable

regulations to avoid injury or damage to parts of the pump.

The unit has been designed and built in such a way that it requires a minimum level of required maintenance. Nevertheless, it is

recommended to always keep the body of the equipment clean and periodically check the tube joints in order to be able to readily

detect any leaks.

ATTENTION: Before any maintenance or cleaning operation, make sure that hydraulic feed and electric power

are disconnected.

9.1.

PUMP DISASSEMBLY

•

Empty the reservoir;

•

Disconnect the piping;

•

Loosen the securing screws;

•

Remove the reservoir, taking particular care for the models fitted with a grease pusher spring (could be loaded);

•

Remove the pump and any filters;

•

Unscrew the hydraulic cylinder from the pump, paying particular attention to the load the spring has;

•

Remove all the other components.

Before reassembling the pump, all the components should be washed with petroleum and lubricated.