SECTION 5

MAINTENANCE

Page 24

OM560C99/1E

DRESSTA

BRAKES

CRITERIA OF BRAKE SHOE AND BRAKE DISC REPLACEMENT

1. Brake shoe should be replaced when its minimum thickness (without steel plate) is 3.2 mm

when measured at any place

2. Brake disc should be flat and smooth. Circumferential scratches must not be deeper than 0.5

mm. Repair by grinding and precise turning is allowed. Minimum allowable thickness of disc is

18 mm.

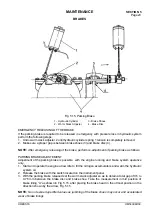

5.8. COOLING SYSTEM

GENERAL

The cooling system operates under pressure. The water pump circulates the coolant through the oil

cooler, engine block, cylinder heads, radiator. The circulation is controlled by the thermostats which

prevent coolant flow through the radiator until the engine reaches the operating temperature. The

proper cooling is assured only when the system is sealed, radiator cap and gasket in good

condition, thermostats operate properly, system is free of coolant and/or air flow restrictions and is

filled to the proper level.

Selection and maintenance of the system coolant is important to long engine life. The following

information provides recommendations for selecting the engine coolant, maintaining the coolant

inhibitors, and servicing the cooling system. This system will operate with a water/antifreeze

mixture or inhibited water as a coolant. Never use water alone because water will allow rust, scale

deposits, and corrosion to occur within the system.

5.8.1. WATER

Use water which has a low mineral content. Water used in conjunction with antifreeze, coolant

filters and inhibited water must meet the following standards:

Total hardness:

Not to exceed 170 parts per million to prevent scale deposits. Water containing

dissolved magnesium and calcium (the usual reason for water hardness) above the specified

amount will cause scale deposits to develop in the engine.

Chlorides

- Not to exceed 100 parts per million to prevent corrosion.

Dissolved solids

- Not to exceed 340 parts per million to minimize sludge deposits, scale deposits

and corrosion.

If any of the requirements cannot be met, use distilled, de-ionized or de-mineralized water. To

determine if the local water supplies meet these standards, water samples can be tested by water

treatment laboratories. Softened water that is prepared using common salt (sodium chloride)

contains excessive amounts of chlorides and should not be used.

5.8.2. ANTIFREEZE

Low silicate ethylene glycol antifreeze is recommended. The antifreeze should contain no more that

0.1% anhydrous alkali metasilicate. Low silicate antifreeze is recommended to avoid the formation

of silica-gel (hydro-gel). This gel formation can occur when the cooling system contains an over

concentration of high silicate antifreeze and/or supplemental coolant additive. DO NOT use

methanol or alcohol as an antifreeze because of its low boiling point. Antifreeze may retain its

freeze protection for more than one season but coolant conditioners must be added to maintain

corrosion protection. Antifreeze formulated with metoxy propanol, or propylene glycol is not

recommended for this system.

Summary of Contents for 560C

Page 1: ...OM560C99 1E OPERATOR S MANUAL 560C SERIAL NUMBERS 15001 AND UP ...

Page 3: ......

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 16: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 18: ......

Page 32: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 34: ......

Page 42: ...SECTION 4 OPERATING ...

Page 43: ......

Page 45: ......

Page 49: ...SECTION 4 OPERATING Page 6 OM560C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Page 88: ...SECTION 5 MAINTENANCE ...

Page 141: ...SECTION 6 SPECIFICATIONS ...

Page 143: ......