SECTION 5

MAINTENANCE

Page 46

OM515C520C99/1E

DRESSTA

HYDRAULIC SYSTEM

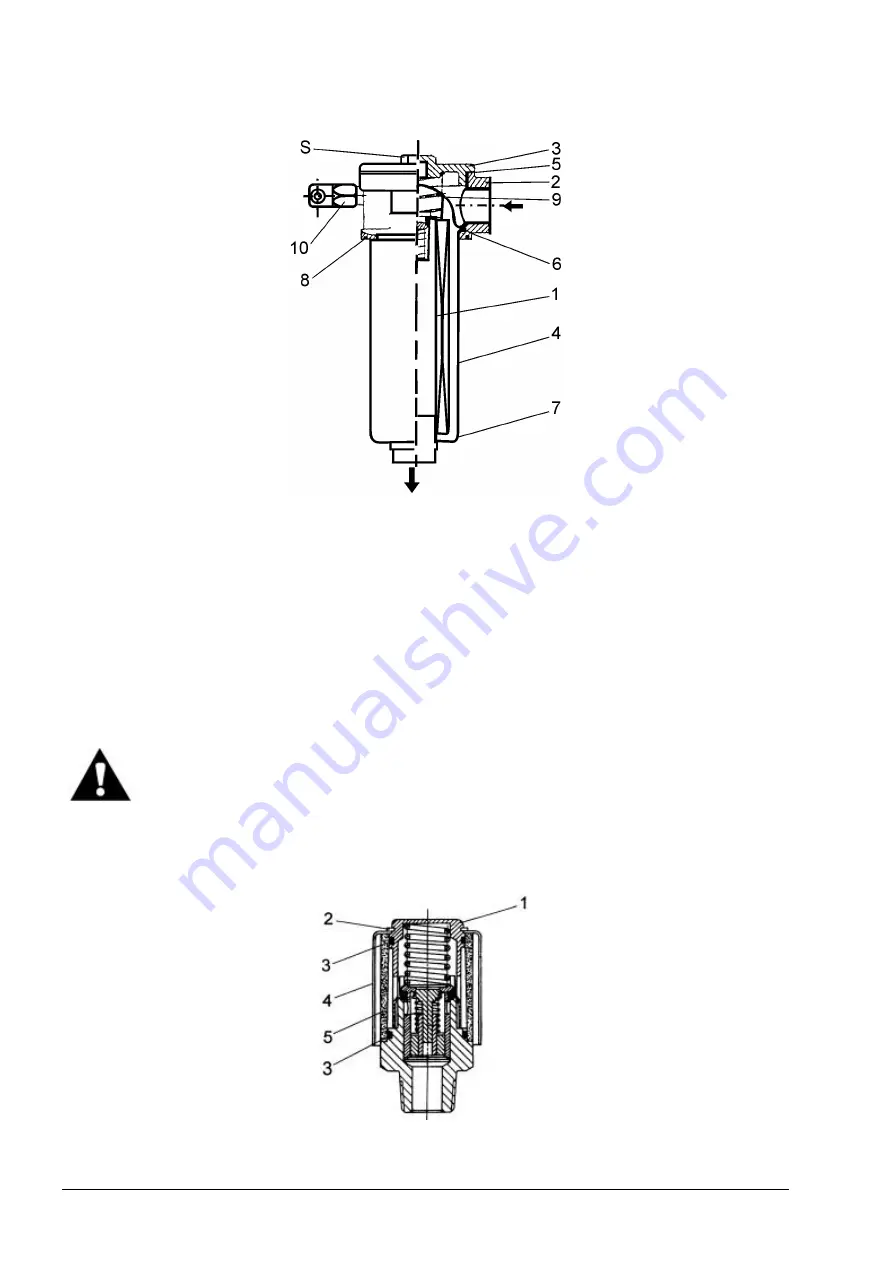

Fig. 5.37A. Hydraulic Reservoir Return Filter (CE Machine)

1. Filter Element

2. Filter Header

3. Cover

4. Filter Housing

5. Gasket

6, 7, 8. O-Rings

9. Spring

10. Oil Filter Restriction Switch

S = 30 mm

5.14.4. SERVICING THE HYDRAULIC RESERVOIR BREATHER

Breather filter (5) should be either cleaned or replaced periodically (Fig. 5.38).

1. Loosen the filter cap on the reservoir to relieve system pressure.

2. Remove retaining ring (2) and cover (4).

WARNING! Wear eye protection when using air or water under pressure to clean

parts. Limit air pressure to 200 kPa and water pressure to 270 kPa.

3. Remove filter (5) and clean in a commercial solvent and dry with compressed air (or replace).

4. Check seal rings (3) for wear or deterioration. Replace if necessary.

5. Reinstall filter (5) (cleaned or new) and cover (4). Secure with ring (2).

6. Tighten the reservoir filler cap.

Fig. 5.38. Hydraulic Reservoir Breather

1. Cap

2. Retaining Ring

3. Filter Seal

4. Cover

5. Filter

Summary of Contents for 515C

Page 3: ...OM515C520C99 1E DRESSTA ...

Page 5: ......

Page 7: ......

Page 10: ...SECTION 1 INTRODUCTION ...

Page 12: ......

Page 17: ...SECTION 2 SAFETY PRECAUTIONS ...

Page 19: ......

Page 37: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Page 39: ......

Page 49: ...SECTION 4 OPERATING ...

Page 51: ......

Page 107: ...SECTION 5 MAINTENANCE ...

Page 165: ...SECTION 6 SPECIFICATIONS ...

Page 167: ......

Page 181: ...SECTION 6 SPECIFICATIONS Page 16 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Page 182: ...SPECIFICATIONS SECTION 6 Page 17 DRESSTA OM515C520C99 1E WIRING DIAGRAMS ...

Page 187: ...SECTION 6 SPECIFICATIONS Page 22 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...