– 8 –

2

FIG.

(11.1)

(11.2)

(11.3)

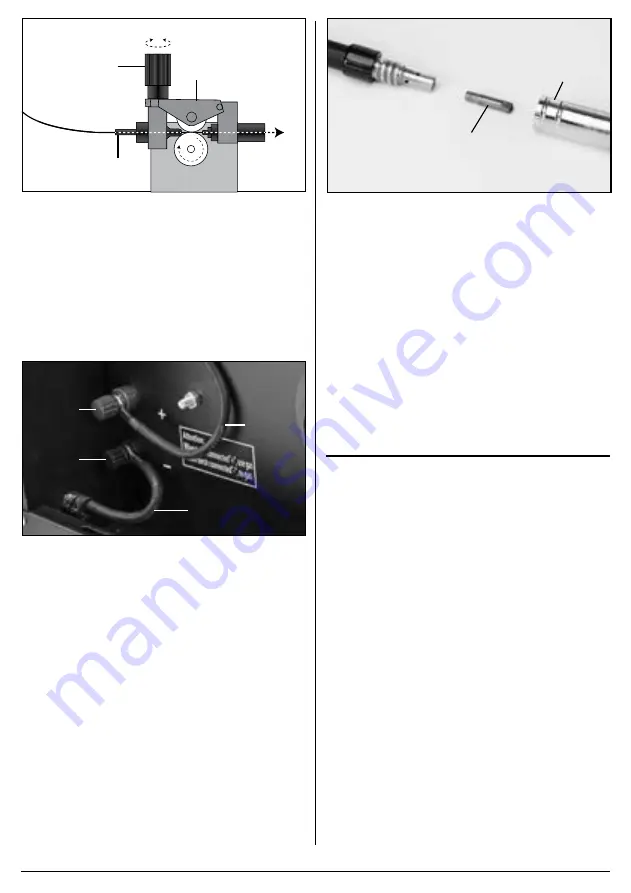

8. GASLESS (no-gas / flux cored).

The polarity of the torch and earth clamp must be

made correctly to suit the gas setup.

i. Attach the earth clamp connector

(10.1)

to the

positive terminal

(16.1)

.

ii. Attach the welding torch connector

(11.1)

to the

negative terminal

(16.2)

.

Note:Reverse the torch and earth clamp for gas

welding.

3

FIG.

(16.1)

(10.1)

(11.1)

(16.2)

9. Press the feed trigger on gun and observe the wire

feed mechanism. If the wire is being fed correctly it

will come out of the swan neck. If it jams you will

need to remove the gas shroud

(2.1)

and with a

small spanner unscrew and remove the tip

(2.2)

.

Pass the tip over the wire and secure back onto the

swan neck. Do not over tighten. Resecure the gas

shroud and trim the wire back as required.

Note: Ensure the tip size matches the wire size prior to

installing.

4

FIG.

(2.2)

(2.1)

7.5 NO GAS WELDING PRINCIPLE

For a successful weld joint, the molten metal must be

protected from contaminating gases found in the air.

This is achieved by using a flux cored filler wire. The flux

is produced as the wire melts.

The flux creates a coating over the weld and once

cooled will need to be removed by chipping it off.

If allowed to cool naturally some areas of the flux may

ping off of the weld by themselves due to thermal

contraction for this reason it is recommended that eye

protection is worn.

8. BASIC WELDING

OPERATION

NOTE: Although this machine is medium weight and

portable take care.

Note: Welding is a mix of science and art and due to the

complex principles and vast differences in parameters

(ie. Material type, position, condition etc.) That

information is well beyond the scope of this manual.

Draper Tools suggest training be obtained from a third

party or refer to a suitable reference book on the subject

additionally; nothing can beat practice using the welder

on scrap material to get a better understanding.

8.1 ON/OFF SWITCH - FIG. 5

The on/off switch is a rocker switch. Press the top half in

to switch the welder ‘on’ and the bottom half in to switch

the welder ‘off’.