OM/SM-AH-CE

13

d.

Remove the low water sensor from the

g.

Once the burners ignite, ensure that the

jacket.

sparking sequence stops and the burners

e.

Replace in reverse order.

f.

Ensure a suitable sealant is used to seal the

not remain lit, then adjustment to the

low water level sensor coupling.

sparking or sensing electrode is required.

g.

Once the low water level sensor is in place,

check the jacket water level. See Paragraph

3.3, Jacket Fillings.

3.14

Removal of Burners

-

(Turn the gas

and electricity mains off)

a.

Undo union on gas pipe to burner manifold.

glass.

b.

Remove the two retaining nuts securing the

c.

Replace with new pressure gauge ensuring

burner manifold to the combustion chamber.

that an adequate sealing compound is used.

c.

Carefully support the weight of the burner

d.

Once the pressure gauge has been

manifold and lower the assembly to a safe

replaced, the kettle jacket will need to be

position.

vented. See Paragraph 3.2, Jacket

d.

The burner is accessible and the orifice can

be changed as required.

e.

Replace in reverse order.

Always check for gas soundness when any part

of the gas circuit has been disturbed.

3.15

Removal of Pilot Assembly

(Spark/Sensing Electrodes)

-

(Turn

the gas and electricity mains off)

a.

Undo the compression fitting on the pilot

line attached to the burner.

b.

Remove the two retaining screws securing

the spark electrode/pilot bracket on the

burner.

c.

Withdraw the pilot assembly from the burner

chamber. The pilot orifice can now be

changed as required

d.

Disconnect the high temperature lead wire

connection to the sparking electrode or the

sensing electrode as required.

e.

Replace in reverse order.

f.

Ensure that there is an adequate spark at

the sparking electrode and that the burners

light smoothly and without delay.

remain lit.

h.

If the burners do not light, or ignite but do

3.16

Removal of Pressure Gauge

-

(Turn

the gas and electricity mains off)

a.

Remove control panel (Paragraph 3.5).

b.

Using the correctly sized spanner remove

the pressure gauge from the top of the sight

Vacuum.

3.17

Removal of Sight Glass - (Turn the

gas and electricity mains off)

a.

Remove control panel (Paragraph 3.5).

b.

Remove sight glass protection bars.

c.

Undo top and bottom compression fittings.

d.

Allow the water in the sight glass to drain.

e.

Remove the sight glass.

f.

Replace in reverse order.

g.

Once the sight glass has been replaced,

the lost jacket water needs to be replaced.

See Paragraph 3.3. Jacket Filling.

3.18

Removal of Safety Valve

-

(Turn the

gas and electricity mains off)

See detailed Instructions on Page 8 pertaining

to Safety Valve installation and operation.

a.

Remove the elbow from the safety valve.

b.

Remove the safety valve from kettle jacket

pipework.

c.

Replace in reverse order

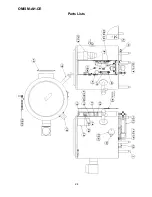

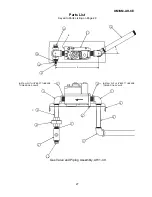

Summary of Contents for GROEN AH-20

Page 23: ...OM SM AH CE 23 ...

Page 24: ...OM SM AH CE 24 Parts Lists ...