22. Lubricate piston sleeve and piston glide

surface in the housing lightly with sili-

cone-free oil.

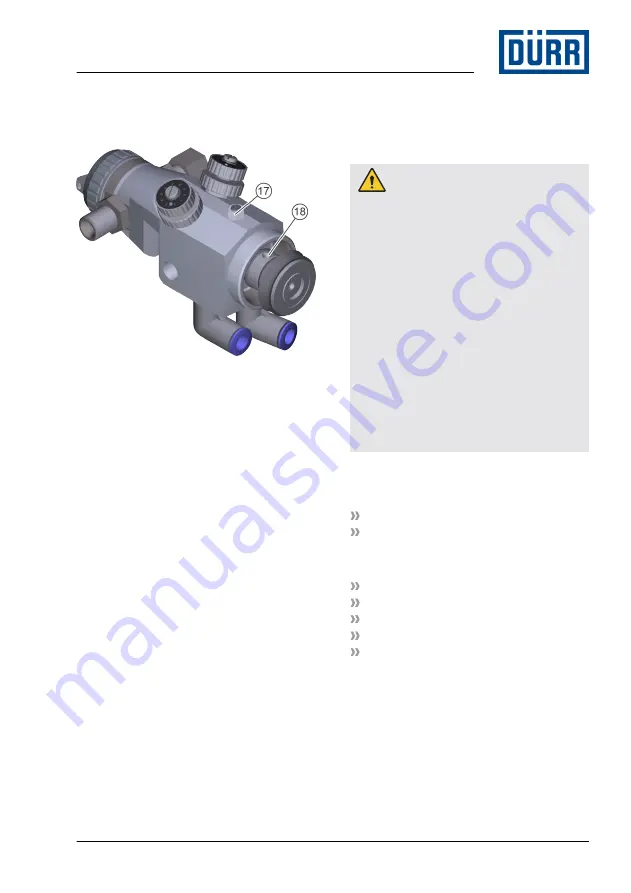

Fig. 26: Insert piston axis

23. Ensure that the tapering bore of the

piston axis (18) is perpendicular to the

tapped hole (17) in the housing.

24. Push in complete piston axis from

behind into the housing.

25. Thread in the screw (2).

26. Screw on hex nut (1) and tighten it.

27. Lubricate needle shank lightly with sili-

cone-free oil. Push in needle (4) care-

fully into the housing from the back.

28. Insert needle spring (5) and plunger

spring (6).

29. Fit end cap (7).

30. Fit cap nut (8). Tighten by hand.

10

Disassembly and Disposal

10.1 Safety recommendations

WARNING!

Material escaping under pressure

Material leaking under high pressure can

penetrate the body. Even if the injury looks

like a harmless cut wound, the penetrating

material leads to amputation, serious inju-

ries can cause death.

– Do not try to seal leakages using body

parts, gloves or towels.

– If there are injuries, seek medical

attention immediately.

Before working on the product:

– Disconnect the system, in which the

product is installed, from compressed

air and material supply.

– Secure the system against being

switched on again.

– Depressurize the lines.

10.2 Disassembly

Personnel:

Operator

+ additional qualification explosion pro-

tection

Protective equipment:

Use ear protection

Eye protection

Respiratory protection device

Protective workwear

Protective gloves

1. Rinsing

2. Disconnect the compressed air supply

and material feed. Secure against recon-

nection.

Disassembly and Disposal

02/2020

EcoGun AA AUTO - MSG00008EN

27/48