44

OPTIONS

7/20, P65

DESCRIPTION

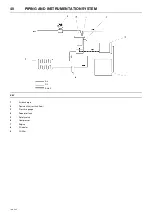

The internal air line lubricator is used to release a lubricant into the

internal compressed air piping before it exits the compressor, from

there the air/oil mixture will flow to the compressed air operated

appliance; one that requires an external source of pneumatic oil for

proper operation.

SAFETY

GENERAL INFORMATION

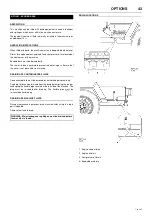

Oil capacity:

2 litres

Oil specification:

Refer to the Tool Manufacturer’s Manual.

OPERATING INSTRUCTIONS

COMMISSIONING

Check the lubricator oil level and fill as necessary.

PRIOR TO STARTING

Check the lubricator oil level and replenish as necessary.

MAINTENANCE

Check the lubricator oil level and replenish as necessary.

FAULT FINDING

OPTION - LUBRICATOR

WARNING: Ensure that the lubricator filler cap is re-tightened

correctly after replenishing with oil.

WARNING: Do not replenish the lubricator oil, or service the lu-

bricator without first making sure that the machine is stopped

and the system has been completely relieved of all air pressure

(Refer to STOPPING THE UNIT in the OPERATING INSTRUC-

TIONS section of this manual).

CAUTION:

If the nylon tubes to the lubricator are disconnected then

ensure that each tube is re-connected in its original location.

FAULT

CAUSE

REMEDY

No oil flow.

Incorrect

connection.

Reverse the nylon tube

connections to the lubricator.

Summary of Contents for 7/20

Page 9: ...DECALS 7 7 20 P65 Engine oil drain Cold Start Procedure...

Page 18: ...16 GENERAL INFORMATION 7 20 P65 VARIABLE HEIGHT RUNNING GEAR FIXED HEIGHT RUNNING GEAR...

Page 50: ......

Page 51: ......

Page 52: ......