C1000X & C3000X PRINT HEAD POSITIONING

77144 Issue 8 August 2009

137

C1000X & C3000X

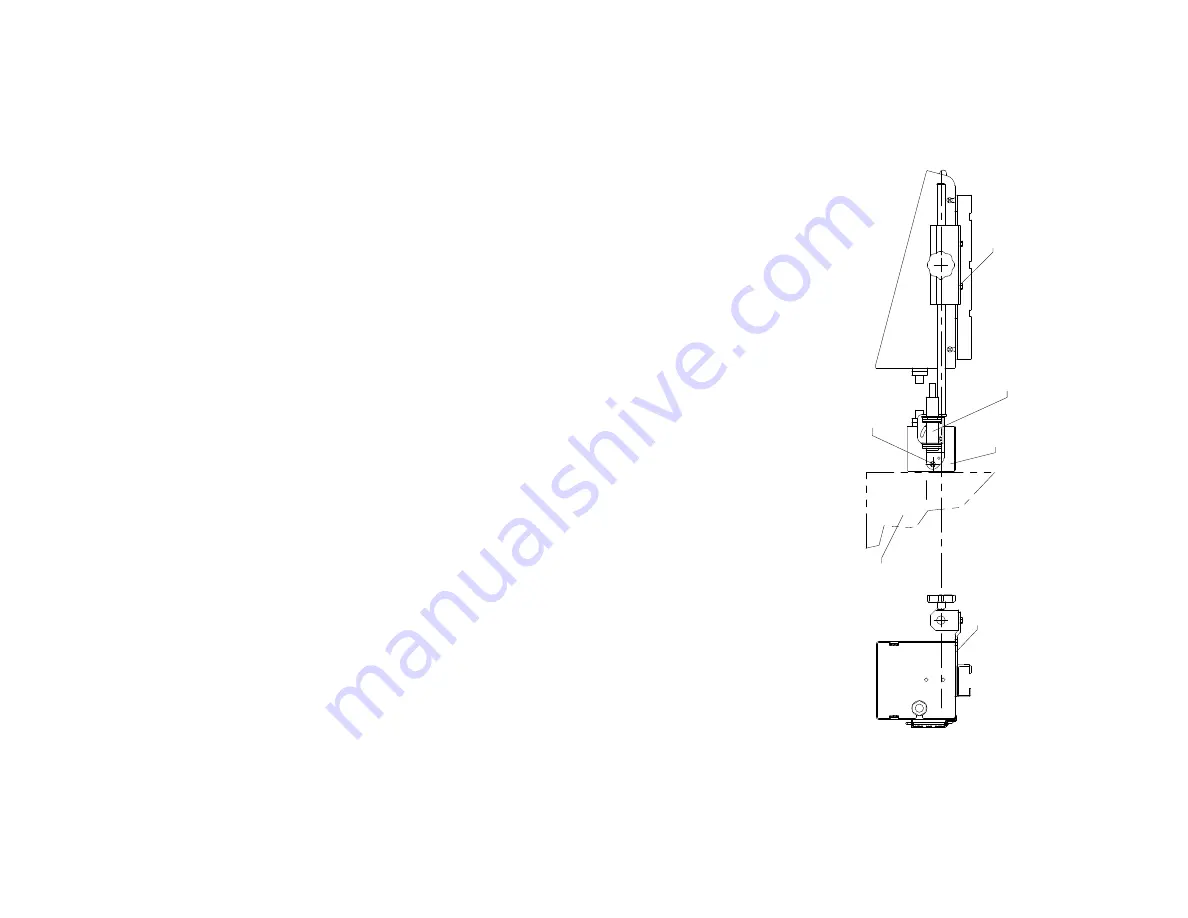

PRINT HEAD POSITIONING

Mounting Plate

Mounting Plate

Print Head Mounting Position When Printing Horizontal

When printing horizontal − Head is mounted in

position "A" and mounting plate is off−set downwards

as shown. Product sensor (if head mounted) is set horizontal.

Product/

Subtrate

Position A

Head

Product

Sensor

Summary of Contents for C1000 plus

Page 1: ...C Seriesplus Printer Operation and Maintenance Manual ...

Page 2: ...2 77144 Issue 8 August 2009 THIS PAGE INTENTIONALLY BLANK ...

Page 12: ...INTRODUCTION 12 77144 Issue 8 August 2009 THIS PAGE INTENTIONALLY BLANK ...

Page 17: ...BASIC OPERATIONS 77144 Issue 8 August 2009 17 2 Litre Base Unit ...

Page 18: ...BASIC OPERATIONS 18 77144 Issue 8 August 2009 200ml Base Unit ...

Page 24: ...BASIC OPERATIONS 24 77144 Issue 8 August 2009 Conveyor ...

Page 62: ...BASIC OPERATIONS 62 77144 Issue 8 August 2009 THIS PAGE INTENTIONALLY BLANK ...

Page 64: ...BASIC OPERATIONS 64 77144 Issue 8 August 2009 THIS PAGE INTENTIONALLY BLANK ...

Page 145: ...DIMENSION DRAWINGS 77144 Issue 8 August 2009 145 Base Unit Width 162 0 6 37 200ml Base Unit ...

Page 147: ...DIMENSION DRAWINGS 77144 Issue 8 August 2009 147 C6000 MF ...

Page 148: ...DIMENSION DRAWINGS 148 77144 Issue 8 August 2009 C6000 MF ...

Page 149: ...DIMENSION DRAWINGS 77144 Issue 8 August 2009 149 C6000i ...

Page 150: ...DIMENSION DRAWINGS 150 77144 Issue 8 August 2009 C6000i ...

Page 151: ...DIMENSION DRAWINGS 77144 Issue 8 August 2009 151 C3000 ...

Page 152: ...DIMENSION DRAWINGS 152 77144 Issue 8 August 2009 C3000 ...

Page 153: ...DIMENSION DRAWINGS 77144 Issue 8 August 2009 153 C3000X ...

Page 154: ...DIMENSION DRAWINGS 154 77144 Issue 8 August 2009 C3000X ...

Page 155: ...DIMENSION DRAWINGS 77144 Issue 8 August 2009 155 C1000 ...

Page 156: ...DIMENSION DRAWINGS 156 77144 Issue 8 August 2009 C1000 ...

Page 158: ...DIMENSION DRAWINGS 158 77144 Issue 8 August 2009 C1000X ...

Page 165: ...OPERATOR NOTES 77144 Issue 8 August 2009 165 ...

Page 166: ...166 77144 Issue 8 August 2009 ...

Page 170: ...THIS PAGE INTENTIONALLY BLANK ...