User manual in Original

Doc. ref: 500A_MB_am_en_210602

DISPERATOR AB

Tel: 08-724 0160

E-mail: [email protected]

Mälarvägen 9, 141 71 Segeltorp

We page: www.disperator.se

36 / 41

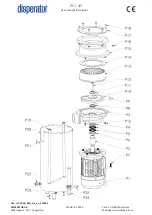

16. Examine the contact surfaces of the carrier (P2) for wear caused by the axle seals. There should

only be two small symmetrical (

barely noticeable)

tracks on the carrier (P2) if it is to be reused. If

the tracks are noticeable, asymmetrical or more than two, replace the carrier.

17. Terminate dismantling here if carrier (P2) and motor (P1) are not to be replaced. Start the

reassembling of the disposer from item 5 in section 9.5. below.

The V-ring seal (P8) and the two axle seals (P5) with special grease (P26) together with

stationary seals (P14) and (P17) must be replaced at each dismantling.

18. In Service Package 2 a

disassembly screw

(P31)

for the carrier

(P2) is included. Use this screw on

top of the carrier and screw it down. This will remove the carrier from the motor axle. If needed,

use the rotary shredder (P10) as a handle to prevent the motor axle from rotating. Alternatively,

hold the carrier with a pair of pliers and a soft cloth in between as shown in the photo below.

19. When changing the motor (P1), make sure that the new motor has the same classification

and quality as the original. The motor must have two holes in the upper flange to allow for

ventilation and drainage of water condensation (see arrows on photo below and original motor).

When drilling these holes in the motor upper flange, it is important to drill at the correct angle,

so that it does not penetrate the motor winding. All replacement motors delivered by Disperator

have premade drainage holes.

Summary of Contents for EXCELLENT 500A-MB Series

Page 2: ......