User manual in Original

Doc. ref: 500A_GTS-E65_am_en_210608

DISPERATOR AB

Tel: 08-724 0160

E-mail: [email protected]

Mälarvägen 9, 141 71 Segeltorp

Web page: www.disperator.se

25 / 48

24 / 48

6.5. Start Up and Final Testing

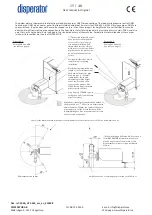

Fasten the laminated operating and safety instructions (included in delivery) in a

place on the wall / bulkhead where they are easily seen by the operator before the

start of the machine.

6.5.1. Check before Start Up

Disconnect the power on the main electrical security breaker (placed on the

wall/bulkhead) and lock it with a padlock if you need to leave the machine

before this section 6.5 is completed.

Check that the rotary shredder in the inlet opening of the disposer turns freely 360° in both

directions by hand, and make sure that no foreign object has been dropped into the grinding unit

during installation.

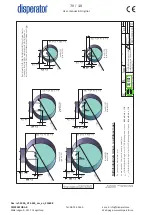

6.5.3. Checks during Start-up

a) Start the GTS-processor and determine that the grinder and pump rotate. For correct

function anti-clockwise rotation of the pump is a must (see item 6.4.7.b above).

b) Check for automatic flushing water pulse at predetermined intervals (from factory

recommended and adjusted to every 15 sec). The first water pulse should come directly

when starting the machine.

c) Also check that extra flushing water flows when pushing blue springback push button.

d) When the yellow springback push button is pressed, check that only the pump is running and

that it then empties the inlet hopper on liquid into the drain line.

e) Check assembly, flushing water connections and drain connections for possible leaks.

f) Make sure that the safety interlock switch works properly according to section 6.4.8 above.

6.5.2. Important Preparations before Starting-up the Machine

In case there is a shut-off valve in the machine´s outlet pipe (drainpipe), this valve must be

opened before starting the machine. The pump of the machine must never run against a closed

valve.

Pour a bucket of water mixed with 1 dl of hand dishwashing detergent into the inlet opening of

the machine. This liquid mixture will give the pump the necessary lubrication during start up.

The pump should never run dry.

6.5.4. Setting the Monitoring of the Pump’s Temperature

See section 6.4.9. above. The display for the monitoring of the pump’s operating temperature is

in

the enclosure placed on the inside of the cabinet’s right-hand door

, and managed as follows:

a) If no key is pressed, the measured operating temperature in the pump stator is given on the

display.

b) Press the SET-key, and the pump switch-off temperature is indicated.

c) Press the SET-key and simultaneously the up arrow-key

↑,

or the down arrow-key

↓

, and

the pump switch-off temperature is increased or decreased. Release the arrow-key before

releasing the SET-key, and the new set temperature will be stored.

d) Check the function of the temperature guard for the pump stator by adjusting the display

to the room temperature where the machine is installed. Restart the machine. If the

temperature guard is operating as required, the machine after a while shall stop.

e) In order for the machine to operate without stop also when processing hot food waste, it

is recommended that the monitor is adjusted to a switch-off temperature of +50

°C.

The

monitor may never be adjusted to a higher value than +69

°C

switch-off temperature.

f) If the switch-off temperature is exceeded, or power failure or short circuit occurs, the

machine is turned off, and the display will flash while a buzzer will sound. The flash and

summer signals are switched off by pressing the down arrow-key

↓

.

g) Sensor failure code is stored and shown on the display also after the defect has been

corrected, and is erased by pressing the down arrow-key

↓

.

Summary of Contents for 500A-GTS-E65 EXCELLENT SERIES

Page 2: ......