109

<

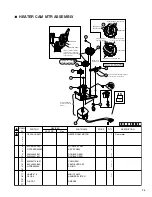

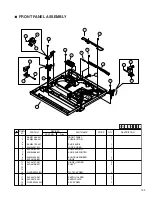

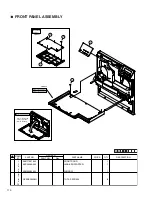

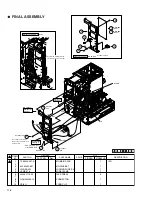

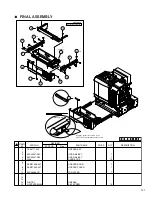

FRONT PANEL ASSEMBLY

1

KKM11036-001

FRONT PANEL

1

2

KKM34086-001

PUSH BUTTON

1

3

4

KKM34139-001

SLIDE KNOB

1

5

KJM34087-001

LOCK SLIDER

1

6

KJS46162-001

COMP. SPRING

1

7

KJM34088-001

SLIDE SUPPORTER

1

8

9

KJM34090-001

SHOCK ABSORBER

2

10

KJP46156-B01

HINGE

2

11

KJP46157-A01

HINGE HOLDER

2

12

KJD46158-001

SHAFT

2

13

14

15

QYSDSF3008N

TH. TAP SCREW

9

16

17

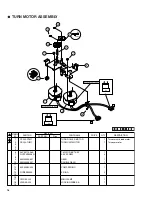

KJP46274-A01

EARTH HOLDER

1

18

KJP46275-001

EARTH PLATE

1

19

QYSPSPL2004N

ASY SCREW

2

20

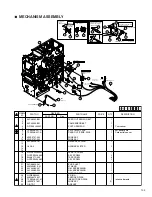

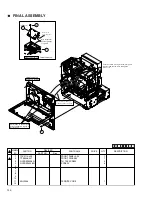

SYMBOL

NO.

PRICE

PART NO.

PART NAME

QTY

DESCRIPTION

REVISED

PART NO.

Rev.

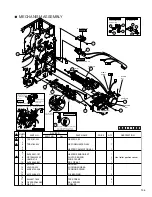

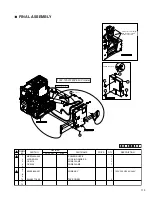

1

2

4

5

7

6

9

9

10

11

12

15

15

15

15

15

10

11

12

18

17

19