Arc-Zone.com, Inc.

2091 Las Palmas Drive, Ste. F

Carlsbad, CA 92011 - Tel. 1.760.931.1500

Email: [email protected]

Copyright©2017, Arc-Zone.com®, Inc. All Rights Reserved

11 / 13

Document: DGP-MANUAL-P3-V2 | DGP-PG3-V2 Product User Manual | Released: 7/11 Rev. C

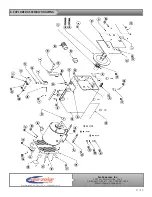

10. VACUUM SYSTEM OVERVIEW

The DGP-PG3-V2 comes with a tool cabinet and integrated vacuum system for the collection of tungsten

dust. This feature has become very popular due to the disclosures in the past few years about the danger of

inhaling dust from the commonly used 2% Thoriated tungsten. This danger is because 2% Thoriated tungsten

is radioactive and is a known cancer causing element. Please contact your local OSHA office if you would like

more information about this issue. In addition, we offer free samples of non-radioactive alternative tungsten,

which performs better in most applications.

It is impossible to contain all of the lightweight dust particles that deflect quickly off the wheels from grinding.

The vacuum system offers a way of collecting the majority of the dust that is produced while grinding and

cutting tungsten electrodes. Replacement vacuum filters are in stock at the factory and ready for immediate

shipment. Installation instructions come with replacment filters. Filter replacement is a very quick and easy

process.

Page 11

TROUBLESHOOTING CHART

SYMPTOMS

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Grinder won’t start

1. Blown line or tripped circuit breaker

1. If fuse is blown, replace

with fuse of proper size.

If breaker is tripped reset it.

2. Low line voltage

2. If voltage is less than rated,

check size of wiring from

main switch on property. If

OK, contact power company.

3. Material wedged between wheel & guard

3. Remove material wedged

between wheel and guard.

Excessive vibration

1. Improper mounting of grinder or accessories

1. Remount

2. Improper wheel mounting

2. Remount wheels but rotate one

wheel 1/4 turn with respect to its

previous position. Other wheel

would retain its original position.

Grooved wheel

1. Electrode pushed with excessive force.

1. Use recommended grinding

times table

2. On steep angled tungsten,

2. Use short collets availabe from

collet touching wheel

Diamond Ground Products.

Motor is overheating

1. Motor not turning freely (without power)

1. Clean around wheels & shaft.

Then replace bearing.

Document: DGP-MANUAL-P3-V2 | DGP-PG3-V2 Product User Manual | Released: 7/11 Rev. C

10. VACUUM SYSTEM OVERVIEW

The DGP-PG3-V2 comes with a tool cabinet and integrated vacuum system for the collection of tungsten

dust. This feature has become very popular due to the disclosures in the past few years about the danger of

inhaling dust from the commonly used 2% Thoriated tungsten. This danger is because 2% Thoriated tungsten

is radioactive and is a known cancer causing element. Please contact your local OSHA office if you would like

more information about this issue. In addition, we offer free samples of non-radioactive alternative tungsten,

which performs better in most applications.

It is impossible to contain all of the lightweight dust particles that deflect quickly off the wheels from grinding.

The vacuum system offers a way of collecting the majority of the dust that is produced while grinding and

cutting tungsten electrodes. Replacement vacuum filters are in stock at the factory and ready for immediate

shipment. Installation instructions come with replacment filters. Filter replacement is a very quick and easy

process.

Page 11

TROUBLESHOOTING CHART

SYMPTOMS

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Grinder won’t start

1. Blown line or tripped circuit breaker

1. If fuse is blown, replace

with fuse of proper size.

If breaker is tripped reset it.

2. Low line voltage

2. If voltage is less than rated,

check size of wiring from

main switch on property. If

OK, contact power company.

3. Material wedged between wheel & guard

3. Remove material wedged

between wheel and guard.

Excessive vibration

1. Improper mounting of grinder or accessories

1. Remount

2. Improper wheel mounting

2. Remount wheels but rotate one

wheel 1/4 turn with respect to its

previous position. Other wheel

would retain its original position.

Grooved wheel

1. Electrode pushed with excessive force.

1. Use recommended grinding

times table

2. On steep angled tungsten,

2. Use short collets availabe from

collet touching wheel

Diamond Ground Products.

Motor is overheating

1. Motor not turning freely (without power)

1. Clean around wheels & shaft.

Then replace bearing.

t

10. VACUUM SYSTEM OVERVIEW