16

GB

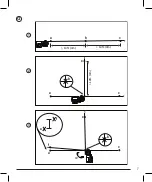

Ceiling Height

Allowable Distance

Between Marks

2.5 m

1.7 mm

3.0 m

2.1 mm

4.0 m

2.8 mm

6.0 m

4.1 mm

9.0 m

6.2 mm

90º Accuracy Between Vertical Beams

Checking 90º accuracy requires an open floor area

at least 33’ x 18’ (10m x 5m). Refer to Fig.e

A

for the

position of the laser at each step and for the location of

the marks made at each step. Always mark the center

of the beam’s thickness.

1.

Place the laser on a smooth, flat, stable surface

that is level in both directions.

2.

Move the Power/Transport Lock switch to the right

to turn the laser ON.

3.

Press to turn on the side vertical beam.

4.

Mark the center of the beam at three locations

(

a

,

b

,

c

) on the floor along the side laser line.

Mark

b

should be at the midpoint of the laser line

(Fig.

G

1

).

5.

Pick up and move the laser to

b

.

6.

Press to turn on the front vertical beam too

(Fig.

G

2

).

7.

Position the front vertical beam so it crosses

precisely at

b

, with the side beam aligned with

c

(Fig.

G

2

).

8.

Mark a location

e

along the front vertical beam at

least 14’ (4m) away from the unit (Fig.

G

2

).

9.

Rotate the laser 90º so the side vertical beam now

passes through

b

and

e

(Fig.

G

3

).

10.

Directly above or below

a

, mark

f

along the

front vertical beam.

Distance

Between Walls

Allowable Distance

Between

a

and

c

10.0 m

6.0 mm

12.0 m

7.2 mm

15.0 m

9.0 mm

Vertical Beam

Checking the vertical (plumb) calibration of the

laser can be most accurately done when there is a

substantial amount of vertical height available, ideally

30’ (9m), with one person on the floor positioning

the laser and another person near a ceiling to mark

the position of the beam. It is important to conduct

a calibration check using a distance no shorter than

the distance of the applications for which the tool will

be used.

1.

Place the laser on a smooth, flat, stable surface

that is level in both directions (Fig.

F

1

).

2.

Move the Power/Transport Lock switch to the right

to turn the laser ON.

3.

Press and to turn on both vertical beams.

4.

Mark two short lines where the beams cross

a

,

b

and also on the ceiling

c

,

d

. Always mark

the center of the beam’s thickness (Fig.

F

2

).

5.

Pick up and rotate the laser 180º, and position it

so the beams line up with the marked lines on the

level surface (

e

,

f

) (Fig.

F

3

).

6.

Mark two short lines where the beams cross on

the ceiling

g

,

h

.

7.

Measure the distance between each set of marked

lines on the ceiling (

c

,

g

and

d

,

h

). If the

measurement is greater than the values shown

below, the laser must be serviced at an authorized

service center.

Summary of Contents for DCE089D1G18

Page 1: ...DCE089G18 3x360 12V 18VLineLaser GB NL GR I FIN D DK ES NO F SE PT TR www 2helpU com ...

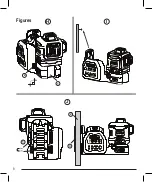

Page 2: ...Figures 2 A B ...

Page 3: ...3 3 1 2 6 4 7 5 C 8 ...

Page 4: ...Figures 4 a b a c a b a b 30 9m _ c b 1 2 3 D ...

Page 5: ...5 a b b a 30 9m _ b c b a c c a c 1 2 3 E ...

Page 6: ...Figures 6 c g 8 2 5m _ 2 d 2 1 2 3 F ...

Page 7: ...7 90 a a a f b c a f c b c e e 14 4m _ 14 4m _ 14 4m _ b 1 2 3 G ...

Page 8: ...Figures 8 3 H 1 I J 2 2 1 ...

Page 9: ...9 5 8 11 1 4 20 K L 1 6 5 2 4 3 ...

Page 10: ...Figures 10 N M ...

Page 149: ...Notes ...

Page 150: ......

Page 151: ......