16

Check list

Check list

Checking of the

assembled

machine

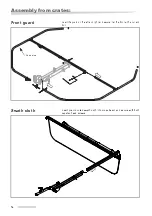

Upon completion of assembly check the following:

>

Check all fastening torques (see table below).

>

Tighten all capstan head screws

>

Tighten all hydraulic connections

>

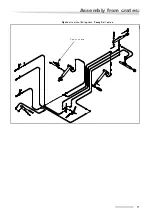

Safe run of hydraulic tubes and cables.

>

Safe connection of all cables.

>

PTO drive shaft connections engaged

>

Check lights

>

Check air pressure (1.5 bar)

Trial run

To fill the hydraulic system with oil requires about 3 litres of hydraulic

oil (SAE 90 API GL4).

Keep slewing range clear

Nobody must be within the slewing range of the machine. Moving parts

can cause injuries.

>

Operate all hydraulic functions of the machine ten times to the limit stops,

in order to remove any air from the system.

>

Upon completion check hydraulic system for leakages