4.10.17

Instruction manual UNIGATE

®

FC - PROFINET 2Port V. 1.5

19

Deutschmann Automation GmbH & Co. KG

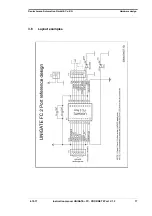

Hardware design

3.7

Handling (mounting the UNIGATE

®

FC on the carrier board)

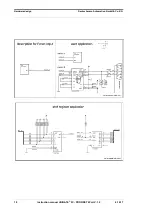

Depending on the application and the expected shock- and vibration-conditions you can choose

from the following possibilities for the UNIGATE

®

FC’s installation on the carrier board:

•

Mounting on a socket in the carrier board. If necessary solder the UNIGATE

®

FC to 2 or 4 pins

in the socket. Normally the FC can easily be pulled out after the soldering points have been re-

moved.

•

Mounting via hole (drilling 3 mm) in the FC board. At the same time a good PE connection is

obtained.

•

Make arrangements for two holes next to the socket in the layout. After the UNIGATE

®

FC was

plugged in the socket pull an isolated wire over the FC and solder it on the carrier board at the

specified holes.

•

Fasten the UNIGATE

®

FC With a wire or a tie wrap on the socket.

•

Manual soldering directly on the carrier board.

•

Automatic soldering directly on the carrier board, whereas „selective“ soldering is essential (no

wave soldering)

The advantage of the socketed variant is the easy download of Script- and Firmware-updates, if

the carrier board is not designed for it. Besides, that way the Fieldbus can be changed easily by

changing the UNIGATE

®

FC. Another advantage is, that - normally - only a reflow soldering of

the carrier board is necessary.

The advantage of the soldered variant is, that the installation height is lower and a higher shock-

and vibration-safety is provided.