8.4.3

Brake

8.4.3.1

General

DANGER

Inappropriate maintenance work

Danger to life and limb. Risk of material damage.

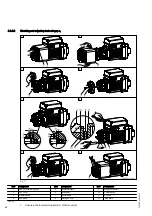

Check brake air gap s

1

at certain intervals and adjust it, as required.

If the brake is not adjusted, it will no longer release after further wear. If the motor then operates against the

applied brake, the brake and motor may be damaged.

Apart from wear, the brake is virtually maintenance-free.

The organic/mineral brake lining is designed in such a way that worn surface particles are only given off as mini‐

mal abrasion. This built-in regeneration of the brake lining surface ensures that the braking characteristics remain

constant. To ensure the brake releases reliably, air gap s

1

must be regularly checked and adjusted, as required.

Brake air gap s

1min

= 0,35 mm - s

1max

= 1,2 mm

The brake disc can be freely turned when the brake is released (power applied to brake coil).

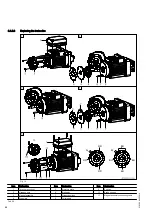

Brake size

B004

B020

Remaining thickness b

min

5

6

Adjusting angle α

1

120°

120°

Tab. 27

When the brake has been adjusted several times, the remaining thickness b

min

of the brake disc must be checked.

The guide pins feature an easily visible mark (x) which clearly indicates the minimum dimension. The brake rotor

must be replaced when this mark is exceeded. A maintenance and spare parts set is available to do this.

The air gap must be adjusted when the max. permissible value s

1

has been reached, (however, immediately if the

brake no longer releases).

For DRF units fitted with KBF motors, see "KBA, KBF motor assembly instructions"

214

39

5 44/120

914

41

Summary of Contents for DRF 200

Page 51: ...214 395 44 120914 51...