23

23

Danfoss District Energy

VI.GP.P1.02

DKDHR

Instructions

VX Solo II

8.0 Filling, Start-up

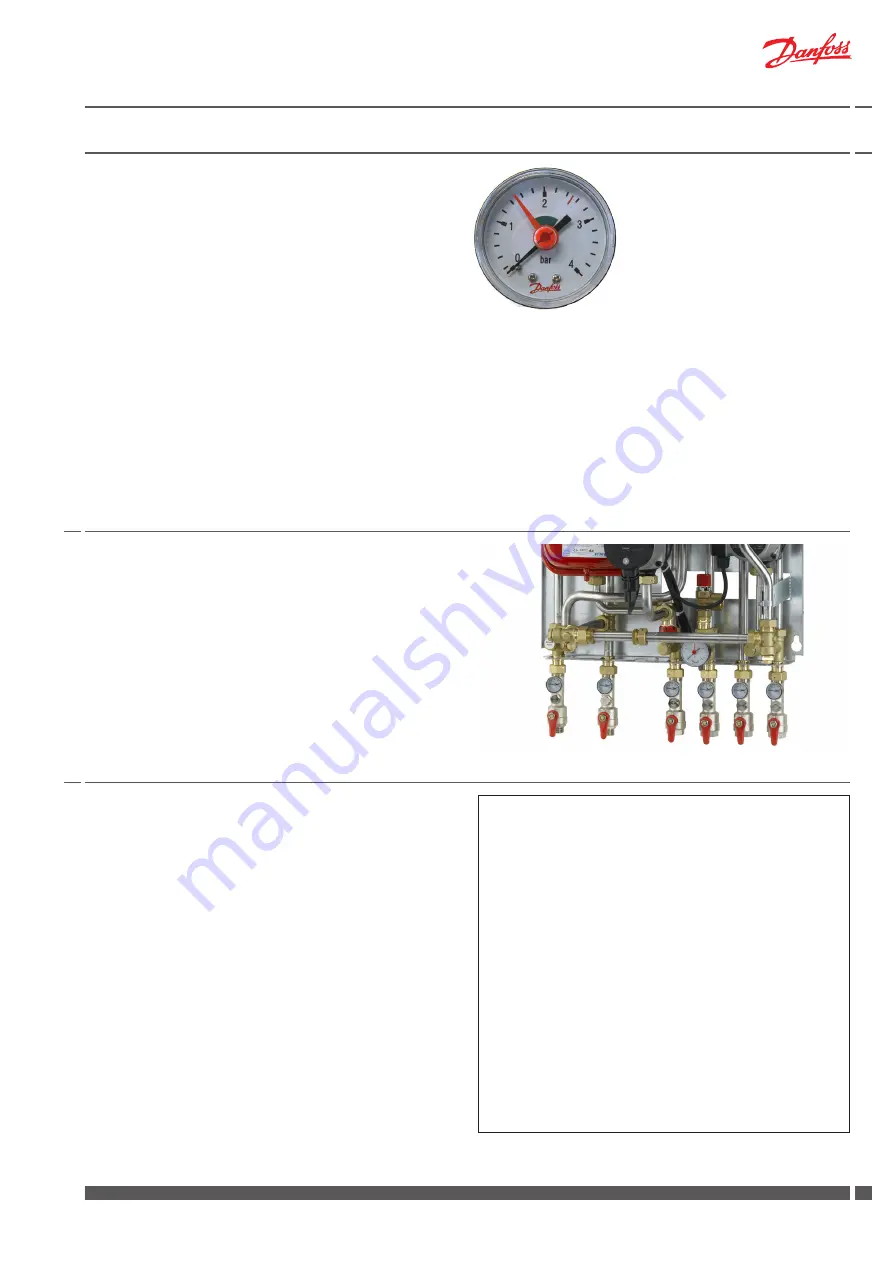

9.0 Manometer and filling

10.0 Electrical connections

Controller ECL 210/310

Supply voltage:

230 V a.c. - 50 Hz

Voltage range:

207 bis 244 V a.c. (IEC 60038)

Power consumption

5 VA

Load on relay outputs:

4(2) A - 230 V a.c

Load on triac outputs:

0,2 A - 230 V a.c.

Actuator AMV10 / AMV13 / AMV 150

Supply voltage:

230 V a.c. - 50 Hz

Power consumption:

2 / 7 VA

For further information please refer to the enclosed instructions.

Pump(s) (Alpha2 L)

Supply voltage:

230 V a.c. - 50 Hz

Protection class:

IP42

Power consumption:

Max. 25 Watt

(UPS pump max. 45 Watt)

For further information please refer to the enclosed installation and

operating instructions for the pump(s).

Check and tighten all connections before adding water to the system,

as vibrations during transport may have caused leaks.

After having added water to the system, tighten all the connections

before performing leak test.

Then heat up the system and tighten the connections once again.

Before adding water to the system and first start-up, check if:

- pipes are connected according to the circuit diagram,

- expansion vessel, if any, is connected,

- heat meter is mounted,

- shut-off valves are closed,

- threaded and flanged connections are tightened.

Adding water to the system:

1. Pump must be switched off when water is added to the system.

2. Fill heat exchanger and system with water until the manometer

shows a working pressure, which corresponds to the system

5 m (approx. 1.5 - 2.0 bar)

3. Deaerate the system completely.

4. Start the pump.

If the pressure drops below 1 bar, water must be added to the system.

The operating pressure should never exceed 2.5 bar.

(The safety valves open at 3 bar)

If system pressure drops dramatically within a short time, heating

system should be examined for leakage, - this includes checking

the factory set pressure of the expansion vessel.

Note;

Filling of water to the heating system must be done outside the

substation.

The station is wired and tested in the factory.

Electrical connections between the controller, pump (s), sensor and

actuator (s) are made.

The electrical connection of the substation must be performed by a

qualified and authorised electrician in compliance with all applicable

rules and regulations.

The station should be connected to a 230 V AC power supply.

Connection of power supply must be established in accordance with

current regulations and local standards.

The station must be wired and connected to an external main switch

so that it can be turned off during maintenance, cleaning or repair

work.