+

_

+

_

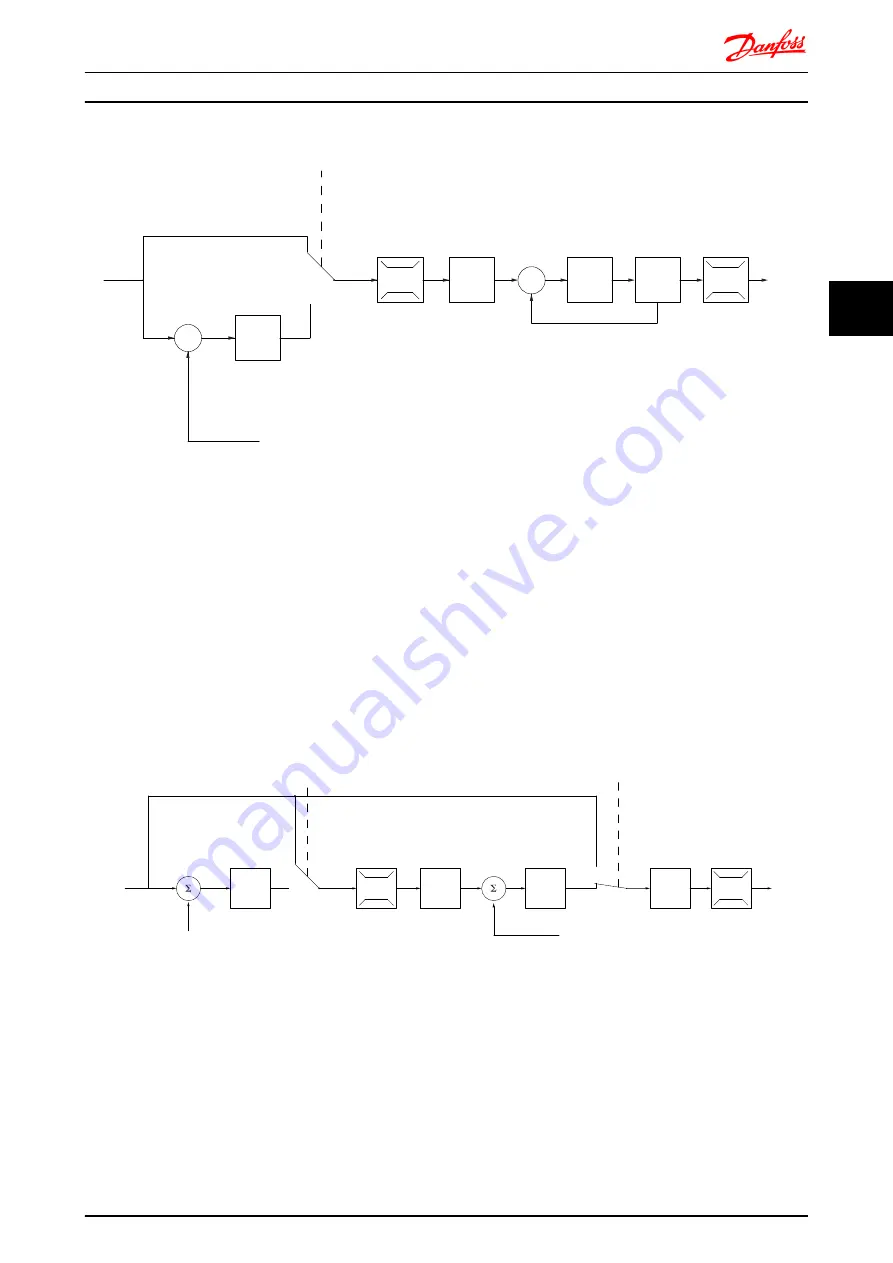

130BA053.11

Ref.

Config. mode

P 1-00

P 7-20 Process feedback

1 source

P 7-22 Process feedback

2 source

Process

PID

P 4-11 Motor speed

low limit [RPM]

P 4-12 Motor speed

low limit [Hz]

P 4-14 Motor speed

high limit [Hz]

P 4-13 Motor speed

high limit [RPM]

Low

High

Ramp

P 3-**

+f max.

P 4-19

Max. output

freq.

Motor

controller

-f max.

Speed

PID

P 7-0*

Illustration 4.16 Control Structure in Flux Sensorless

In the configuration shown,

1-01 Motor Control Principle

is

set to

[2] Flux sensorless

and

1-00 Configuration Mode

is set

to

[0] Speed open loop

. The resulting reference from the

reference handling system is fed through the ramp and

speed limitations as determined by the parameter settings

indicated.

An estimated speed feedback is generated to the Speed

PID to control the output frequency.

The Speed PID must be set with its P,I, and D parameters

(parameter group 7-0*).

Select

[3] Process

in

1-00 Configuration Mode

to use the

process PID control for closed loop control of speed or

pressure in the controlled application. The Process PID

parameters are found in parameter group 7-2* and 7-3*.

4.5.3 Control Structure in Flux with Motor Feedback

130BA054.11

P 3-**

P 7-0*

P 7-2*

+

_

+

_

P 7-20 Process feedback

1 source

P 7-22 Process feedback

2 source

P 4-11 Motor speed

low limit (RPM)

P 4-12 Motor speed

low limit (Hz)

P 4-13 Motor speed

high limit (RPM)

P 4-14 Motor speed

high limit (Hz)

High

Low

Ref.

Process

PID

Speed

PID

Ramp

P 7-00

PID source

Motor

controller

-f max.

+f max.

P 4-19

Max. output

freq.

P 1-00

Config. mode

P 1-00

Config. mode

Torque

Illustration 4.17 Control Structure in Flux with Motor Feedback

In the configuration shown,

1-01 Motor Control Principle

is

set to

[3] Flux w motor feedb

and

1-00 Configuration Mode

is set to

[1] Speed closed loop

.

The motor control in this configuration relies on a

feedback signal from an encoder mounted directly on the

motor (set in

1-02 Flux Motor Feedback Source

).

Select

[1] Speed closed loop

in

1-00 Configuration Mode

to

use the resulting reference as an input for the Speed PID

control. The Speed PID control parameters are located in

parameter group 7-0*.

Select

[2] Torque

in

1-00 Configuration Mode

to use the

resulting reference directly as a torque reference. Torque

Application Examples

VLT

®

Decentral Drive FCD 302

MG04H102 - VLT

®

is a registered Danfoss trademark

63

4

4