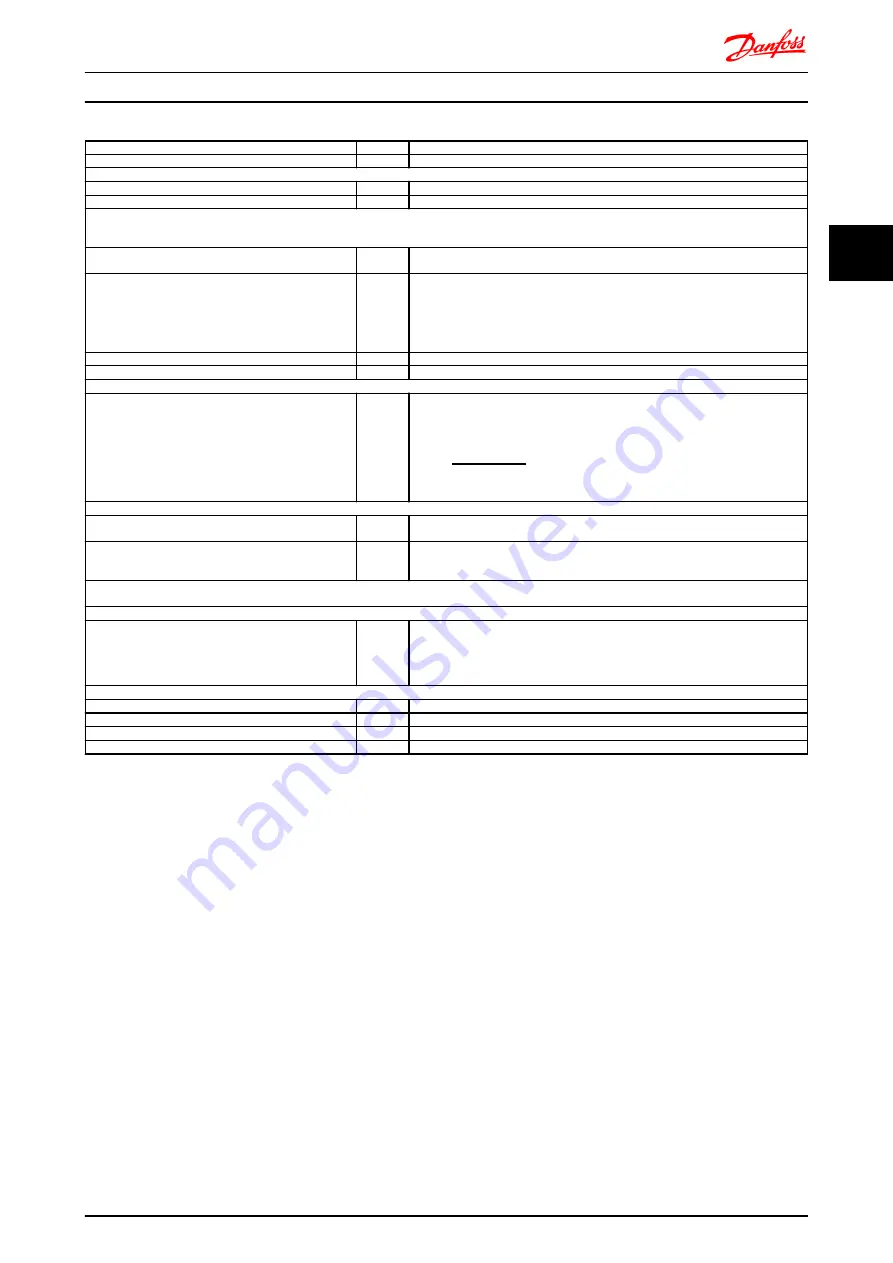

Function

Par. no.

Setting

Initialize the frequency converter

14-22

[2] Initialization - make a power cycling - press reset

1) Set motor parameters:

Set the motor parameters according to name plate data

1-2*

As stated on motor name plate

Perform a full Automation Motor Adaptation

1-29

[1] Enable complete AMA

2) Check that motor is running in the right direction.

When motor is connected to frequency converter with straight forward phase order as U - U; V- V; W - W motor shaft usually turns clockwise seen into shaft

end.

Press “Hand On” LCP key. Check shaft direction by

applying a manual reference.

If motor turns opposite of required direction:

1. Change motor direction in

4-10 Motor Speed Direction

2. Turn off mains - wait for DC link to discharge - switch

two of the motor phases

4-10

Select correct motor shaft direction

Set configuration mode

1-00

[3] Process

Set Local Mode Configuration

1-05

[0] Speed Open Loop

3) Set reference configuration, ie. the range for reference handling. Set scaling of analog input in par. 6-xx

Set reference/feedback units

Set min. reference (10

°

C)

Set max. reference (80

°

C)

If set value is determined from a preset value (array

parameter), set other reference sources to No Function

3-01

3-02

3-03

3-10

[60]

°

C Unit shown on display

-5

°

C

35

°

C

[0] 35%

Ref

=

Par

. 3 − 10(0)

100

× ((

Par

. 3 − 03) − (

par

. 3 − 02)) = 24, 5°

C

3-14 Preset Relative Reference

to

3-18 Relative Scaling Reference Resource

[0] = No

Function

4) Adjust limits for the frequency converter:

Set ramp times to an appropriate value as 20 sec.

3-41

3-42

20 sec.

20 sec.

Set min. speed limits

Set motor speed max. limit

Set max. output frequency

4-11

4-13

4-19

300 RPM

1500 RPM

60 Hz

Set S201 or S202 to wanted analog input function (Voltage (V) or milli-Amps (I))

NOTE! Switches are sensitive - Make a power cycling keeping default setting of V

5) Scale analog inputs used for reference and feedback

Set terminal 53 low voltage

Set terminal 53 high voltage

Set terminal 54 low feedback value

Set terminal 54 high feedback value

Set feedback source

6-10

6-11

6-24

6-25

7-20

0V

10V

-5

°

C

35

°

C

[2] Analog input 54

6) Basic PID settings

Process PID Normal/Inverse

7-30

[0] Normal

Process PID Anti Wind-up

7-31

[1] On

Process PID start speed

7-32

300 rpm

Save parameters to LCP

0-50

[1] All to LCP

Table 3.3 Example of Process PID Control set-up

Optimisation of the process regulator

The basic settings have now been made; all that needs to

be done is to optimise the proportional gain, the

integration time and the differentiation time (

7-33 Process

PID Proportional Gain

,

7-34 Process PID Integral Time

,

7-35 Process PID Differentiation Time

). In most processes,

this can be done by following the guidelines given below.

1.

Start the motor

2.

Set

7-33 Process PID Proportional Gain

to 0.3 and

increase it until the feedback signal again begins

to vary continuously. Then reduce the value until

the feedback signal has stabilised. Now lower the

proportional gain by 40-60%.

3.

Set

7-34 Process PID Integral Time

to 20 sec. and

reduce the value until the feedback signal again

begins to vary continuously. Increase the

integration time until the feedback signal

stabilises, followed by an increase of 15-50%.

4.

Only use

7-35 Process PID Differentiation Time

for

very fast-acting systems only (differentiation

time). The typical value is four times the set

integration time. The differentiator should only be

used when the setting of the proportional gain

and the integration time has been fully

optimised. Make sure that oscillations on the

feedback signal is sufficiently dampened by the

lowpass filter on the feedback signal.

If necessary, start/stop can be activated a number of times

in order to provoke a variation of the feedback signal.

3.4.5 Ziegler Nichols Tuning Method

In order to tune the PID controls of the frequency

converter, several tuning methods can be used. One

approach is to use a technique which was developed in

Introduction to FC 300

FC 300 Design Guide

MG.33.BD.02 - VLT

®

is a registered Danfoss trademark

35

3

3