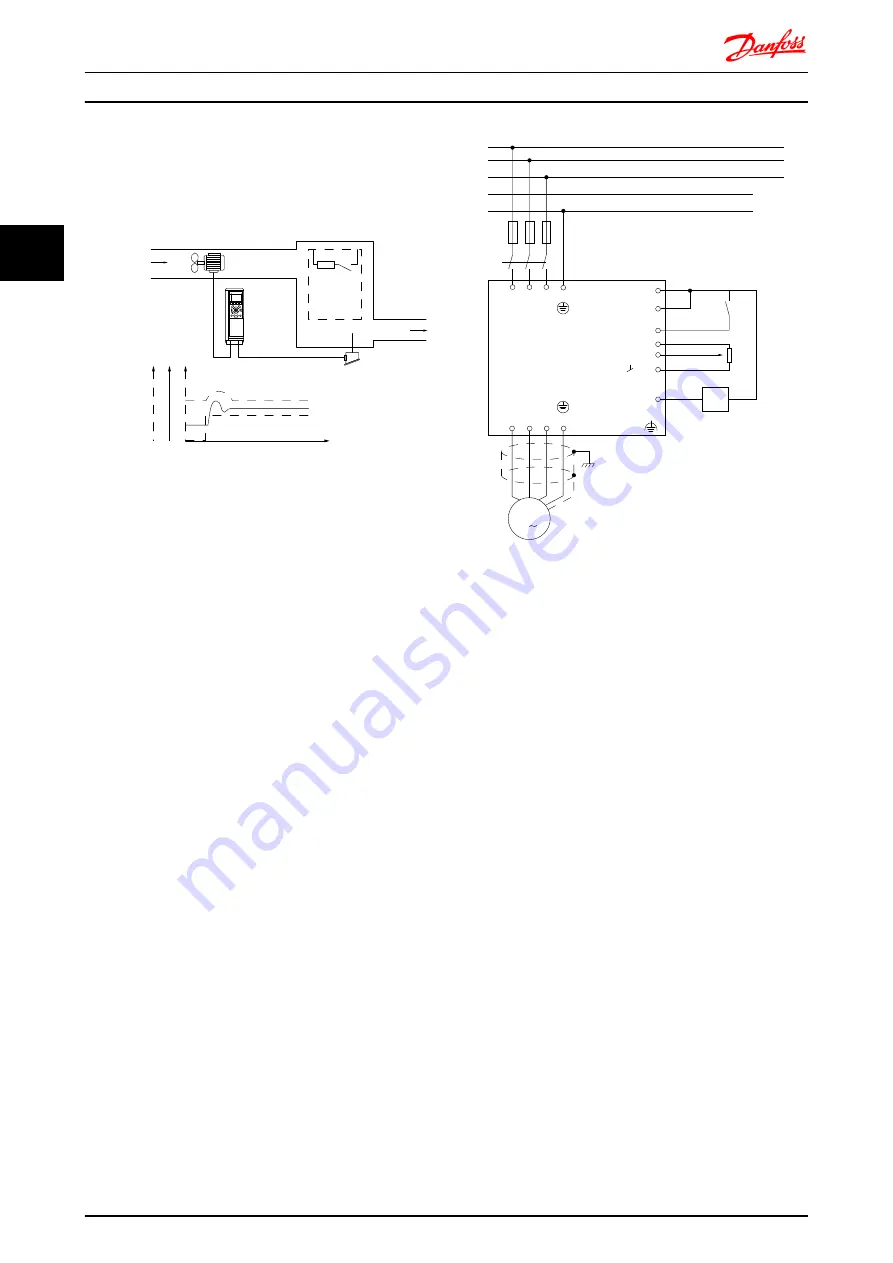

3.4.4 Example of Process PID Control

The following is an example of a Process PID Control used

in a ventilation system:

Temper

atur

e

Fan speed

Temperature

transmitter

Hea

t

Heat

generating

process

Cold air

130BA218.10

100kW

n °C

W

In a ventilation system, the temperature is to be settable

from - 5 - 35°C with a potentiometer of 0-10V. The set

temperature must be kept constant, for which purpose the

Process Control is to be used.

The control is of the inverse type, which means that when

the temperature increases, the ventilation speed is

increased as well, so as to generate more air. When the

temperature drops, the speed is reduced. The transmitter

used is a temperature sensor with a working range of

-10-40

°

C, 4-20 mA. Min. / Max. speed 300 / 1500 RPM.

Transmitter

96 97

99

98

91 92 93 95

50

12

L1 L2

L1

PE

L3

W PE

V

U

F1

L2

L3

N

PE

130BA175.11

18

53

37

55

54

M

3

Illustration 3.7 Two-wire transmitter

1.

Start/Stop via switch connected to terminal 18.

2.

Temperature reference via potentiometer

(-5-35

°

C, 0-10 VDC) connected to terminal 53.

3.

Temperature feedback via transmitter (-10-40

°

C,

4-20 mA) connected to terminal 54. Switch S202

set to ON (current input).

Introduction to FC 300

FC 300 Design Guide

34

MG.33.BD.02 - VLT

®

is a registered Danfoss trademark

3

3