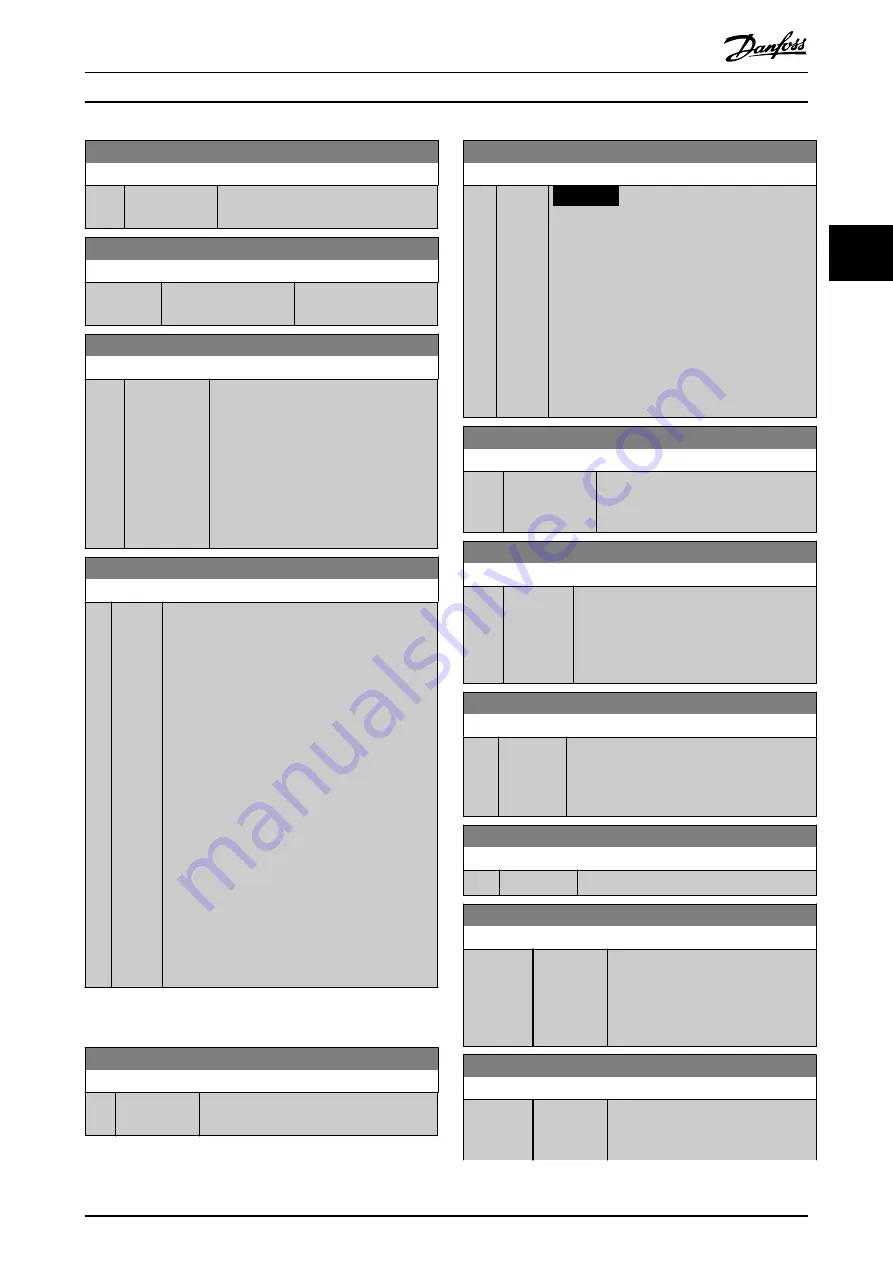

16-23 Motor Shaft Power [kW]

Range:

Function:

0 kW

*

[0 - 10000 kW] Readout of the mechanical power

applied to the motor shaft.

16-24 Calibrated Stator Resistance

Range:

Function:

0.0000 Ohm

*

[0.0000 - 100.0000

Ohm]

Shows the calibrated

stator resistance.

16-25 Torque [Nm] High

Range:

Function:

0

Nm

*

[-200000000

- 200000000

Nm]

View the torque value with sign, applied

to the motor shaft. Some motors supply

more than 160% torque. Therefore, the

minimum value and the maximum value

depend on the maximum motor current

as well as the motor used. This specific

readout has been adapted to be able to

show higher values than the standard

readout in

16-28 Angle Error

Range:

Function:

0 °

*

[-180 -

180 °]

Readout of deviation between sensor less rotor

angle estimation by motor controller and real rotor

angle based on encoder reading. The parameter is

only activated if options in

is set to

[2] Flux Sensorless

and

parameter 1-10 Motor Construction

is set to

[1] PM,

non salient SPM

or

[2] PM, salient IPM

.

The encoder source used for comparison must be

selected in

chapter 3.8.2 7-00 Speed PID Feedback

. To obtain an accurate reading of parameter

16-28, the motor angle offset must be set in

parameter 1-41 Motor Angle Offset

. Rotor detection

is configured in

chapter 3.8.12 7-90 Position PI

which is activated using the

setting in

in

Flux with

motor feedback

.

Parameter 7-90

must be set to

[0]

Motor feedb.P1-02

. The encoder is then only used

for comparison while position control is based on

the estimated sensor less position. This enables to

measure the accuracy of position control in sensor

less mode.

3.16.3 16-3* Drive Status

16-30 DC Link Voltage

Range:

Function:

0 V

*

[0 - 10000 V] View a measured value. The value is filtered

with a 30 ms time constant.

16-31 System Temp.

Range:

Function:

0 °C

*

[-128 -

127 °C]

NOTICE

Valid for FC 302 only.

Shows the highest internal system temperature.

In the smaller enclosure sizes (A–C), the system

temperature matches the control card

temperature measurement in

parameter 16-39 Control Card Temp.

In the larger

enclosure sizes (D–F), the system temperature is

the highest temperature measured on hardware

components with temperature sensors, for

example, the power card(s).

16-32 Brake Energy /s

Range:

Function:

0 kW

*

[0 - 10000 kW] View the brake power transmitted to an

external brake resistor, stated as an

instant value.

16-33 Brake Energy Average

Range:

Function:

0 kW

*

[0 - 10000

kW]

View the brake power transmitted to an

external brake resistor. The mean power is

calculated on an average level based on the

selected time period within

parameter 2-13 Brake Power Monitoring

16-34 Heatsink Temp.

Range:

Function:

0 °C

*

[0 -

255 °C]

View the frequency converter heat sink

temperature. The cutout limit is 90

±

5

°

C (194

±

9

°

F), and the motor cuts back in at 60

±

5

°

C (140

±

9

°

F).

16-35 Inverter Thermal

Range:

Function:

0 %

*

[0 - 100 %] View the percentage load on the inverter.

16-36 Inv. Nom. Current

Range:

Function:

Size

related

*

[0.01 -

10000 A]

View the inverter nominal current,

which must match the nameplate

data on the connected motor. The

data is used for calculation of torque,

motor overload protection, and so on.

16-37 Inv. Max. Current

Range:

Function:

Size

related

*

[0.01 -

10000 A]

View the inverter maximum current,

which must match the nameplate

data on the connected motor. The

Parameter Descriptions

Programming Guide

MG33MP02

Danfoss A/S © 10/2018 All rights reserved.

211

3

3

Summary of Contents for VLT AutomationDrive FC 302

Page 2: ......