VLT

®

6000 HVAC Series

Programming

116 DC brake cut-in frequency

(DC BRAKE CUT-IN)

Value:

0.0 (OFF) - par. 202

Output frequency high limit, f

MAX

✭

OFF

Function:

This parameter is used for setting the DC brake cut-in

frequency at which DC braking is to be activated

in connection with a stop command.

Description of choice:

Set the desired frequency.

117 Motor thermal protection

(MOT. THERM PROTEC)

Value:

No protection (NO PROTECTION)

[0]

Thermistor warning (THERMISTOR WARNING)

[1]

Thermistor trip (THERMISTOR FAULT)

[2]

ETR Warning 1 (ETR WARNING 1)

[3]

✭

ETR Trip 1 (ETR TRIP 1)

[4]

ETR Warning 2 (ETR WARNING 2)

[5]

ETR Trip 2 (ETR TRIP 2)

[6]

ETR Warning 3 (ETR WARNING 3)

[7]

ETR Trip 3 (ETR TRIP 3)

[8]

ETR Warning 4 (ETR WARNING 4)

[9]

ETR Trip 4 (ETR TRIP 4)

[10]

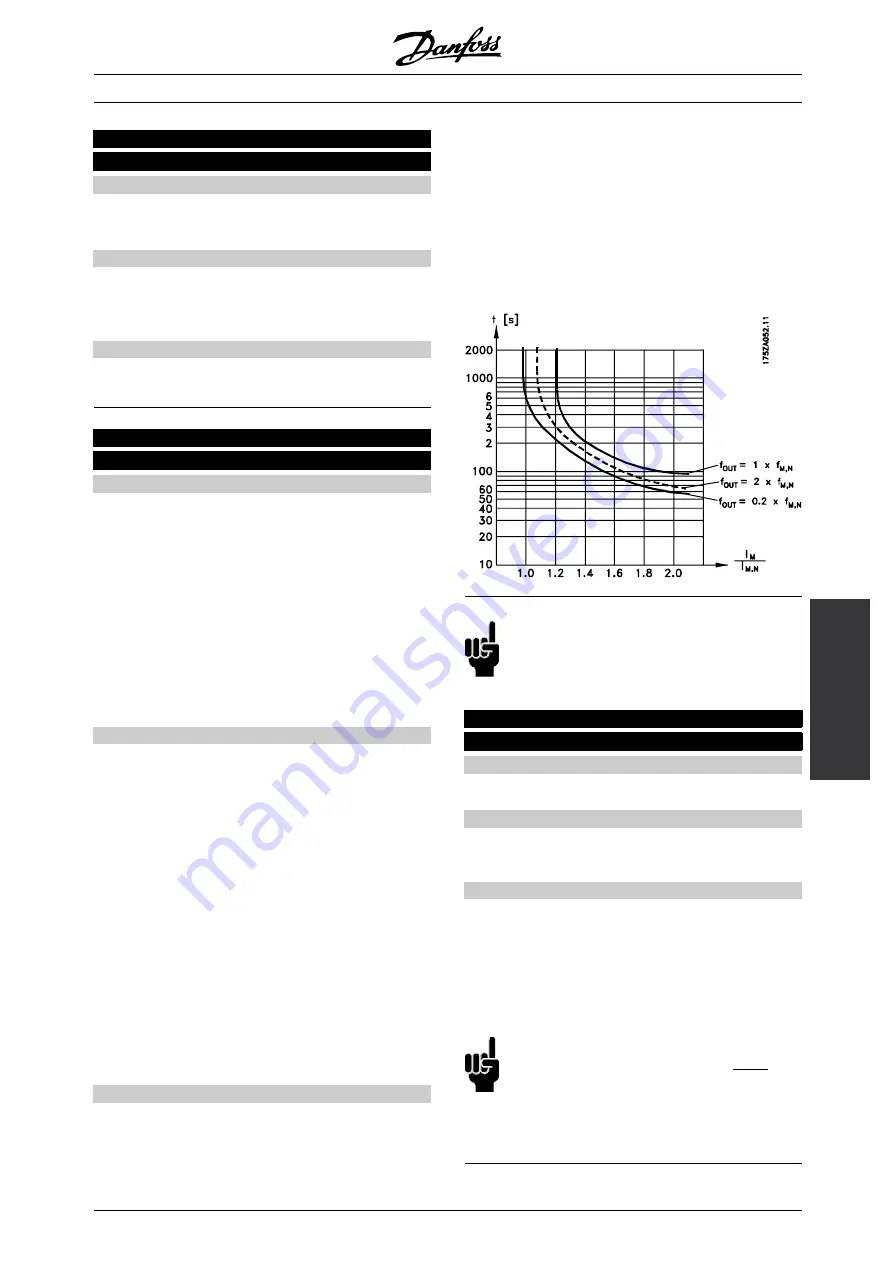

Function:

The frequency converter is able to monitor the motor

temperature in two different ways:

-

Via a thermistor sensor fitted to the motor. The

thermistor is connected to one of the analog

input terminals 53 and 54.

-

Calculation of the thermal load (ETR - Electronic

Thermal Relay), based on the current load and

the time. This is compared with the rated motor

current I

M,N

and the rated motor frequency f

M,N

.

The calculations made take into account the

need for a lower load at lower speeds because

of less cooling in the motor itself.

ETR functions 1-4 do not start calculating the load until

there is a switch-over to the Setup in which they were

selected. This enables the use of the ETR function,

even where two or several motors alternate.

Description of choice:

Select

No protection

[0] if no warning or tripping is

required when the motor is overloaded.

Select

Thermistor warning

[1] if a warning is desired

when the connected thermistor gets too hot.

Select

Thermistor trip

[2] if cutting out (trip) is desired

when the connected thermistor overheats.

Select

ETR Warning 1-4

, if a warning is to come

up on the display when the motor is overloaded

according to the calculations.

The frequency converter can also be programmed to

give off a warning signal via one of the digital outputs.

Select

ETR Trip 1-4

if tripping is desired when the

motor is overloaded according to the calculations.

NB!:

In UL / cUL applications ETR provides class

20 motor overload profection in accordance

with National Electrical Code.

118 Motor power factor (Cos

ϕ

)

(MOTOR PWR FACT)

Value:

0.50 - 0.99

✭

0.75

Function:

This parameter calibrates and optimizes the AEO

function for motors of different power factor (Cos

ϕ

).

Description of choice:

Motors having > 4 poles have a lower power factor

which would restrict or prevent use of the AEO function

for energy savings. This parameter allows the user

to calibrate the AEO function to the power factor of

the motor so that AEO can be used with motors of

6, 8, and 12 poles as well as 4 and 2 poles.

NB!:

The default value is 0.75 and should

NOT

be changed unless the specific motor

has power factor lower than 0.75. This

is typically the case for motors having more than

4 poles or low efficiency motors.

✭

= factory setting. () = display text [] = value for use in communication via serial communication port

MG.61.A5.02 - VLT is a registered Danfoss trademark

91