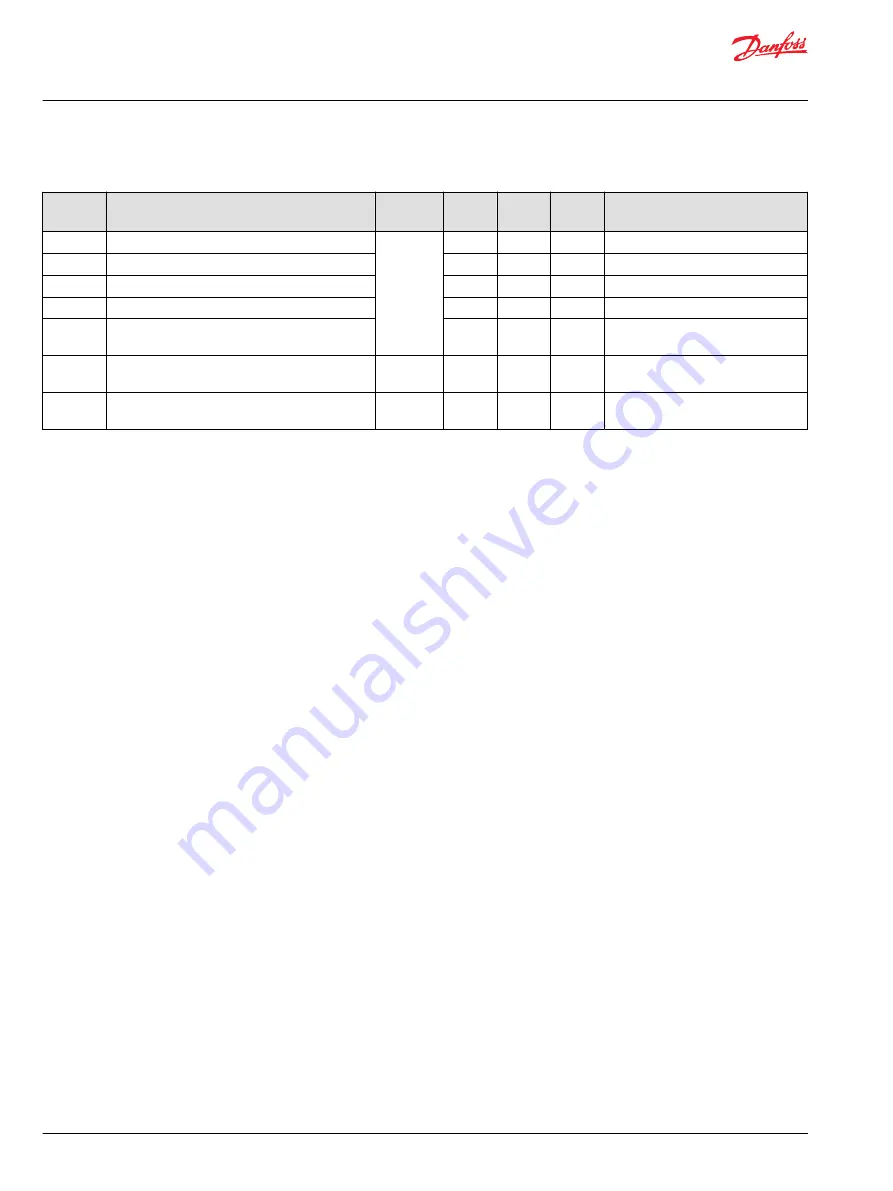

Available J1939 Diagnostic Trouble Codes (continued)

SPN

Description

Lamp

Status

FMI

CM

OC

Corresponding

PVED-CL Error Code

627

Power supply voltage below min. threshold value

Red

4

0

Yes

13030

627

Power supply voltage exceeds max. threshold value

3

0

Yes

13031

1079

Sensor supply voltage below min. threshold value

4

0

Yes

13032

1079

Sensor supply voltage exceeds max. threshold value

3

0

Yes

13033

614

Loss of main spool control or spool position

plausibility check failure

14

0

Yes

13053, 13054

615 (1)

Vehicle speed CAN sensor data plausibility check

failure

Red/Amber 14

0

Yes

13064

615 (2)

Internal PVED-CL error (= any other classified as

critical)

Red

14

0

Yes

any other classified as critical

1. This has been separated from the next row SPN 615 as this is the only case when the DTC with SPN

615 can signal the Lamp status set to Amber.

2. SPN 615 with the Lamp status set to Red indicates that other critical EHPS error has happened. The

user must retrieve an error code from the EHPS error buffer and use the table in section 2 to locate

the source of a problem.

The PVED-CL supports DM1, DM2 and DM3 according to SAE J1939-73 diagnostic protocol (see

PVED-CL

Communication Protocol Technical Information

, 11079551).

A sub-set of all possible PVED-CL fault codes are represented as standardized J1939-73 Suspect

Parameter Numbers (SPN). The sub-set is limited to interface-related faults, which are typically causing

most troubles.

AD1 and/or AD2 Short-circuit

Each of the two analog input ports are monitored for short-circuits to GND, VCC or positive battery

supply. The Failure Mode Identifier (FMI) differentiates between the two type of short-circuits. An internal

pull-down resistor on both analog input ports will pull the input level to GND if an analog input port is

left open. No analog input diagnostic is active if the analog input is not mapped.

Missing CAN Sensor Set-points

SPN 611 indicates a fault due to invalid timing or missing input signals from the sensors, most likely due

to a failing CAN sensor or cable tree fault. In this context, input signals are both CAN messages and

analog samples from sensors. However, missing analog samples or invalid timing of analog samples can

only be caused by an internal PVED-CL fault – nothing can be concluded about the analog sensors from

this SPN.

Invalid timing means that the requirements to the period that data has to be received within, has not

been met. This could again be caused by an incorrectly configured CAN sensor or a heavy CAN bus-load,

restricting the CAN sensor messages to be transmitted at their expected time.

Operation Manual

PVED-CL Controller for Electro-Hydraulic Steering, Version 1.38

Diagnostic & Troubleshooting

104 |

©

Danfoss | May 2016

11025583 | AQ00000216en-US0302