6.2.4 CAN-ID Setting

The

General.BaseCanId

and

General.DefaultCanId

are preset

to 100. All the settings can also be read from the object

dictionary.

There are several ways to set/change the CAN-ID. The

easiest way is setting via the BCD switch.

BCD switch is set to 0

•

The CAN-ID specified as

General.DefaultCanId

on

the SD card will be used.

•

The ISD ID distribution protocol can be used to

give another ID to the box. Note that the ID will

be stored on the SD card as the new

General.DefaultCanId

BCD switch is set to between 1 and 9

•

The CAN-ID is calculated by

General.BaseCanId

+

the value of the BCD switch.

The message for the ID setting over CAN bus is shown in

the table below. Note that the first 4 bytes have to be 0,

otherwise the encoder box ignores the ID setting message.

This is also the case if the BCD switch is not set to 0. After

this message is sent, the new CAN-ID will start flashing on

the encoder box display. Press the <SET> button on the

encoder box to accept the new ID. The encoder box will

only leave this ID setting mode following the acceptance

of the new ID or after an NMT reset.

Note that the other ISD servo system components will also

be in ID setting mode after this message is sent, so an

“NMT reset communication” message has to be sent to

release all devices from this mode.

Note that whilst in ID setting mode, it is not possible to

communicate with the device.

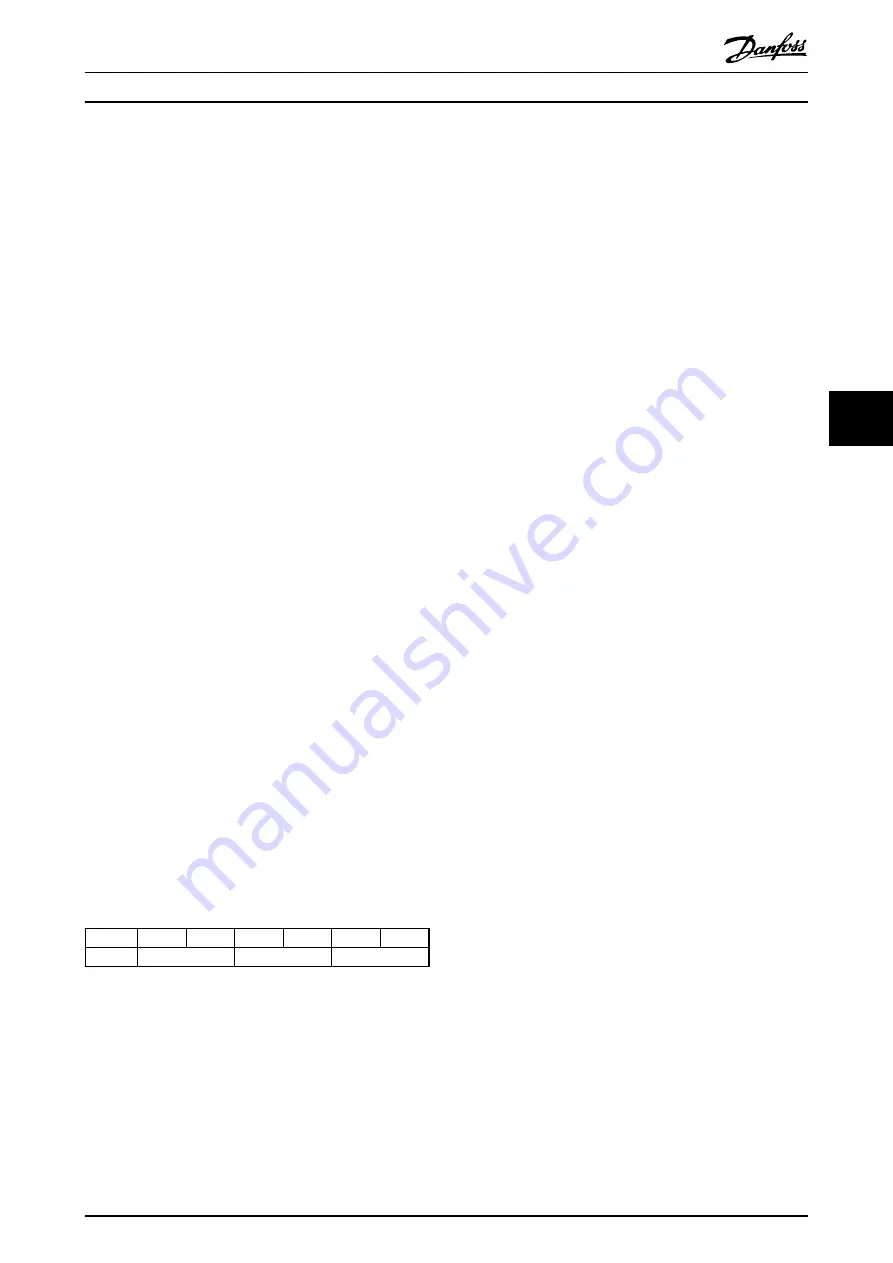

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

0x7F2

0

0

new CAN-ID

Table 6.1 ISD ID Setting Message

6.3 Switching the Encoder Box on

Ensure that the SD card is inserted and that the encoder

box parameter file (MPARAM.dat) exists before switching

on the encoder box. If not, the encoder box cannot be

started and error code “Err2” is shown on the 7-segment

display.

This error can only be reset by inserting an SD card (with a

valid parameter file) and carrying out a re-start (removing

and replacing the mains supply plug).

Furthermore, the CAN bus and the encoder must be

connected to the encoder box correctly.

For the servo system to function correctly, all components

must be wired correctly. Read the operating instructions of

the other ISD components carefully.

Switching on (booting up)

The encoder box parameter file (MPARAM.dat) contains the

parameter list and is automatically read after the encoder

box is switched on.

The pre-configuration of the defined objects for the

chosen encoder takes place. During this initialisation

phase, the LED "Run / Err." flashes green.

CAUTION

Do not remove or replace the SD card during operation,

otherwise the contents of the SD card could be destroyed.

Switch the encoder box off and wait 10 seconds before

removing the SD card.

Commissioning

VLT

®

ISD Encoder Box Operating Instructions

MG75F102 - VLT

®

is a registered Danfoss trademark

21

6

6