If the superheat fluctuates

When the refrigerating system has been made to work steadily,

the controller’s factory-set control parameters should in most

cases provide a stable and relatively fast regulating system.

If the system, however, fluctuates this may be due to the fact that

superheat parameters that are too low have been selected. Before

starting any adjustment of the factory settings check the S2 sensor

location – see page 9:

If adaptive superheat has been selected (n21 = 1):

Adjust: n09, n10 and n18.

If load-defined superheat MSS has been selected (n21 = 2):

Adjust: n09, n10 and n22.

Alternatively it may be due to the fact that the set regulation

parameters are not optimal.

If the time of oscillation is longer than the integration time:

(T

p

> T

n

(T

n

is e.g. 240 seconds))

1. Increase T

n

to 1.2 times T

p

2. Wait until the system is in balance again

3. If there is still oscillation, reduce K

p

by e.g. 20%

4. Wait until the system is in balance

5. If it continues to oscillate, repeat 3 and 4

If the time of oscillation is shorter than the integration time:

(T

p

< T

n

(T

n

is e.g. 240 seconds))

1. Reduce K

p

by e.g. 20% of the scale reading

2. Wait until the system is in balance

3. If it continues to oscillate, repeat 1 and 2.

©Danfoss A/S (AC-MCI / sw), 2014-03

DKRCC.PS.RP0.A1.02/520H7142

15

14

DKRCC.PS.RP0.A1.02/520H7142

©Danfoss A/S (AC-MCI / sw), 2014-03

Manual Superheat controller type EKD 316

Manual Superheat controller type EKD 316

Finding the optimum settings

Details on the controller algorithm and settings

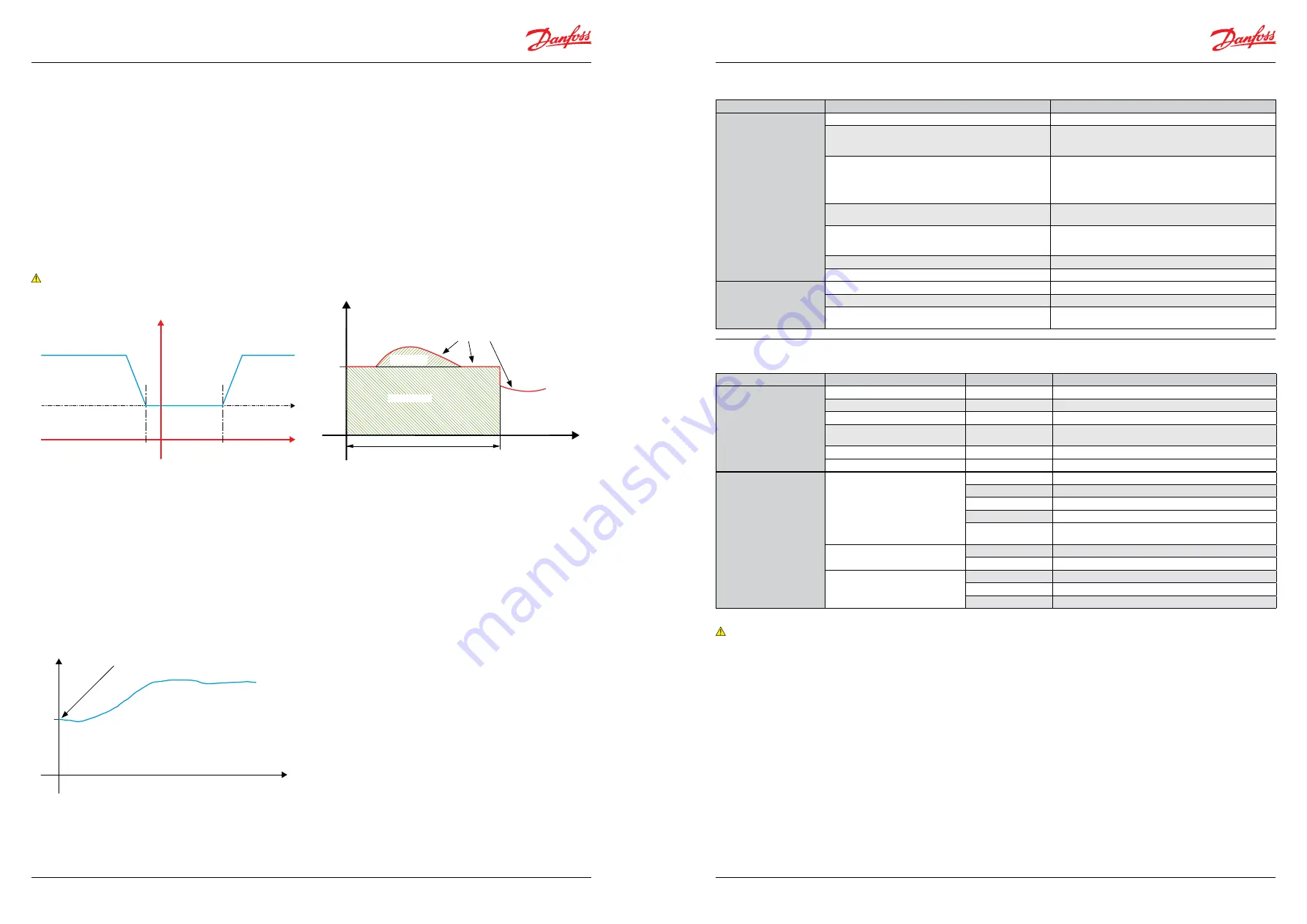

Kp factor (n04) and Kp min (n19)

The Proportional Gain is dependent on the value of the measured

superheat SH relative to Reference superheat SH ref. The

Proportional Gain has the following values relative to superheat SH:

If SH is more than 2.5K greater than SH ref, then Gain equals Kp

factor.

If SH is within the range -0.5 and 2.5K from SH ref, then Gain equals

Kp factor times Kp min.

The reason for this variable Gain is to provide stable superheat for

values near the superheat reference.

Note:

The value of Gain does not change suddenly but gradually when

SH gets close to SH ref.

Initial "Kick start" startup

In general the valve opening degree is controlled by the measured

value of the superheat SH. This means that during certain

situations during startup, the valve will be slow to open due to

the built-up of superheat from a small value. To prevent this from

happening, the valve is given an initial opening degree dependent

on the Kp factor, the measured superheat SH and SH close, as

given in the following relationship:

Initial OD% = kp factor*(SH – SH close)

This procedure is not to be confused with the force opening of the

valve given in the “Problems with startup” section.

Dan

fo

ss

84N375.11

Dan

fo

ss

84N376.11

Problems with startup

Sometimes in one-to-one applications, the valve does not open

sufficiently on startup, and troublesome low pressure trips may

occur. This problem is typical when using the single loop control

where only the SH controls the opening of the valve.

The

force opening of valve

function has been implemented in

the EKD 316 controller. After startup, this function will provide a

constant, set minimum opening degree during a set time period,

regardless of the superheat value. The setting parameters are

called

Start OD%

(n17) and

StartUp time

(n15).

Please observe that the

Start OD%

is a minimum value after

startup and if the measured superheat (u21) produces a value

greater than

Start OD%

then the value will be valve opening

degree (u24) – see the diagram.

Dan

fo

ss

84N378.11

Troubleshooting

Symptom

Possible Cause

Remedy

Suction pressure too low

Pressure drop across the evaporator too high

Lack of subcooling ahead of expansion valve

Check refrigerant ahead of expansion valve.

If the valve is placed much higher than condenser outlet,

check pressure difference.

Evaporator superheat too high

1. Check superheat performance, the settings

SH min and SH max.

2. Check valve capacity.

3. Check that the maximum number of steps of

valve is same as parameter n37.

Pressure drop across the expansion valve less than valve is

sized for

Check pressure drop across expansion valve. Replace with

larger valve.

Expansion valve too small

Check refrigeration system capacity and compare with

expansion valve capacity. Replace with larger valve if

necessary.

Expansion valve block with foreign material

Remove valve and examine the orifice.

Evaporator wholly or partly iced up

De-ice evaporator

Liquid hammer

in compressor

Superheat of expansion valve too low

Increase the values of SH close and SH min.

Superheat reference set too low

Increase the value of SH min

The S2 sensor not in good contact with the suction line

Ensure that S2 sensor is secured on suction line. Insulate

sensor.

Alarms

Symptom

Possible Cause

Fault Message

Remedy

All Light emitting diodes

flashing

E24

S2 sensor fault

E25

S4 sensor fault

Analog input outside range.

E19

Pressure transmitter outside range.

E20

Check pressure transmitter, connections at 14-15 and

pressure.

No refrigerant selected

A11

Select refrigerant

Battery alarm

A44

Check the battery voltage is the nominal voltage.

The controller can give the

following messages

Error message

E1

Fault in controller

E24

S2 Sensor error

E25

S4 Sensor error

E19

The input signal on terminals 21-22 is outside the range.

E20

The input signal on terminals 17-19 is below

minumum limit (P0 signal)

Alarm message

A11

No refrigerant has been selected

A44

Battery alarm (no voltage or too low voltage)

Status codes

S5

MOP

S10

Refrigeration stopped r12=off

non

Regulation, no fault

Note:

1. Only one alarm is displayed at a time in the controller display and are shown in the

order given above. All alarms are displayed in the AKM system.

2. The alarm E19 will only be active if address o10 is set to 1 or more.

3. EKD 316 with change over relay ( 3 terminals 24-25-26)

4. The battery alarm A44 is only active when battery alarm address A34 is set to ON.

Proportional Gain

Reg.OD%

OD%

Start OD%

Start

Start Up time*

Time from start

Normal Reg.

Valve OD%

Forced OD%

Kp factor

Kp factor multiplied Kp min.

SH ref

-0.5

2.5

SH

Start

Time

Kp factor* (SH - SH Close)

When Kp factor = 3, SH = 12, Close = 2

Initial OD % = 30%

OD%