Operation

Superheat function

You may choose between two kinds of superheat regulation,

either:

Minimum stable superheat (MSS)

Load-defined superheat

The regulation modes for controlling superheat

There are two different ways of controlling superheat, i.e.

controlling according to the minimum stable superheat (MSS) and

Load Defined superheat.

The parameter SH mode selects the controlling form where it can

be set to MSS when set to 1, or Load Defined superheat when set

to 2.

Minimum stable superheat (MSS)

The superheat control algorithm will attempt to regulate the

superheat down to the lowest stable value between the minimum

superheat setting, "Min SH" and the maximum superheat setting,

"Max SH".

The superheat reference SH ref is adaptive and adjusted.

When using this form of control, there are three settings that have

major affect on this mode of control.

Max SH – The maximum limit of SH ref.

Min SH – The minimum limit of SH ref. Care should be taken not

to set this value too low in order to avoid flooding back into the

compressor.

Stability – This factor determines how much instability can be

accepted. Small values will cause the SH ref to increase if the

slightest instability in SH is detected. Higher values will accept a

higher degree of instability.

Function

Parameter

Default value

Superheat control -MSS

n21

1

Min Superheat Reference

n10

1 - 12 K

Max Superheat Reference

n09

2 - 15 K

Load define application

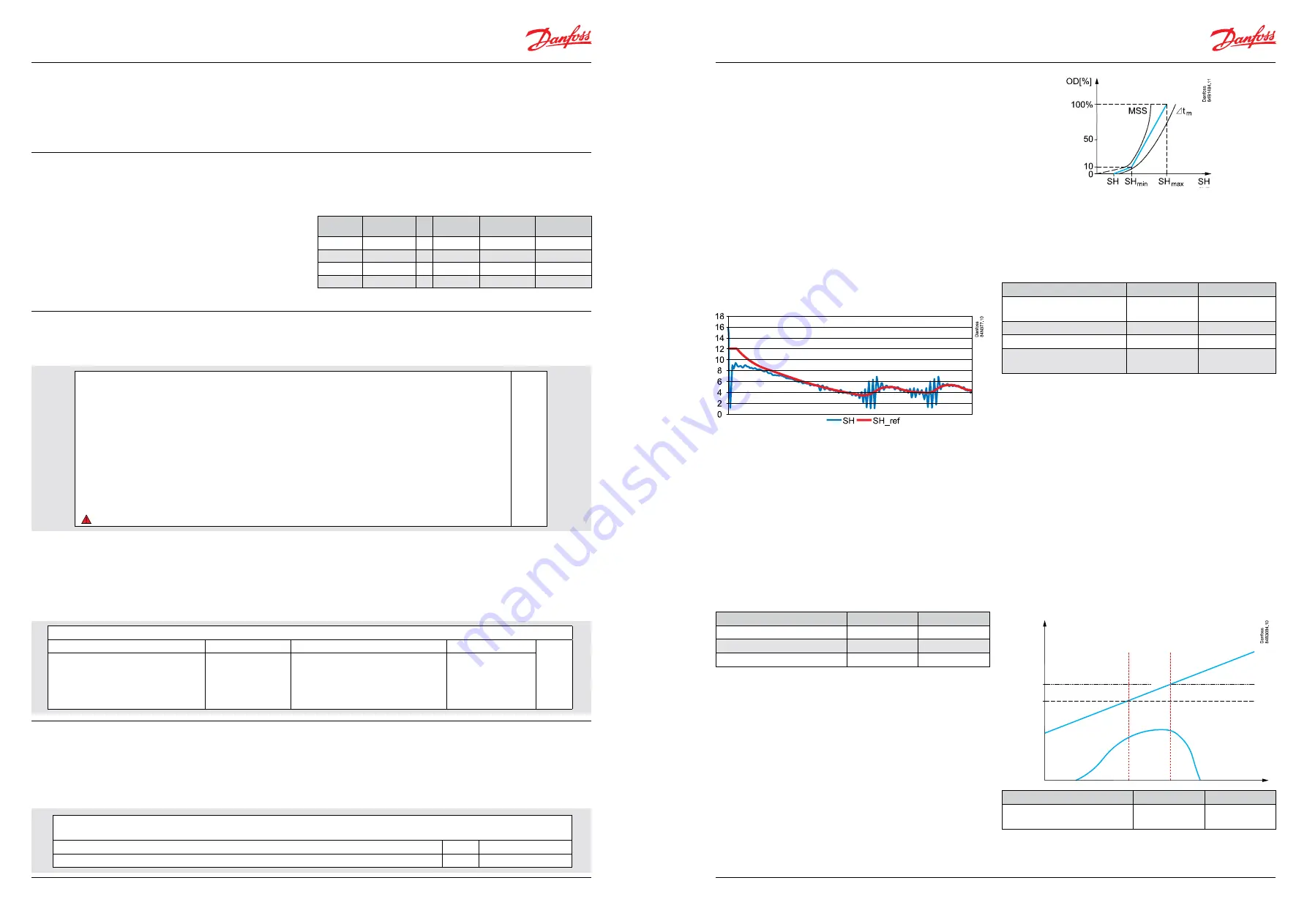

SH ref follows a defined curve as shown below. This curve is

defined by three values: SH close SH max and SH min.

This form of regulation is similar to the thermostatic valve where

the spring force can be adjusted to keep the SH (superheat) in the

stable region to the right of the curve.

The advantage over the thermostatic valve is that there are three

settings to define the operating curve.

The reference follows a defined curve. This curve is defined by

three values: the closing value, the min. value and the max. value.

These three values must be selected in such a way that the curve

is situated between the MSS curve and the curve for average

temperature difference

∆

Tm (temperature difference between

media temperature and evaporating temperature.

Setting example = n22=4, n10=6 and n09=10 K).

Function

Parameter

Value

Superheat control mode -2

= Load define

n21

2

Min Superheat Reference

n10

1 K

Max Superheat Reference

n09

2 K

Value of min. SH ref for loads

under 10%

n22

Must be between

Min and Max SH

Using the MOP

In order to reduce the current to the compressor it is possible to

control the maximum operating pressure of the evaporator.

Evaporator pressure exceeds the "MOP" limit, the valve opening

degree is controlled by the MOP function which will keep the

pressure below the "MOP" limit. This function takes precedence

over the superheat control, so during MOP control the superheat is

not controlled.

The MOP function (address n11) is active when it is set to values

less than 200 bar (200 bar corresponds to off). The pressure value

is converted to the corresponding temperature value and when

the MOP is active, the controller will prevent the evaporating

temperature T1 from exceeding this value.

If Maximum Operating suction Pressure MOP parameter n11 is

reset from factory setting 20 to 1 bar (gauge) From the MOP i.e 1

bar point the OD increases slower and slower until the pressure

reaches MOP + 0.5 i.e 1.5 bar. Subsequently the OD decreases

rapidly as the pressure increases.

Function

Parameter

Value

Maximum operating pressure

MOP

n11

0-200 bar

©Danfoss A/S (AC-MCI / sw), 2014-03

DKRCC.PS.RP0.A1.02/520H7142

11

10

DKRCC.PS.RP0.A1.02/520H7142

©Danfoss A/S (AC-MCI / sw), 2014-03

Manual Superheat controller type EKD 316

Manual Superheat controller type EKD 316

Valve definition

Valve type

Display EKA 164A Valve type

Display EKA 164A

n03

0 = ETS 12.5, ETS 25, KVS 15

1 = ETS 50, CCM 10, CCM 20, CCM 30

2 = ETS 100, CCM 40

3 = ETS 250, KVS 42

4 = ETS 400

25

50

100

250

400

5 = user-defined

6 = Saginomiya UKV/SKV/VKV/PKV

7 = ETS 6

8 = CCMT 2, CCMT 4, CCMT 8

uSr

SA9

6

CC

Working range for pressure transmitter

Depending on the application a pressure transmitter with a given working range is used.

For the range of (-1 to 12 bar), the min. value is set to -1 bar

o20

MinTransPres.

For the range of (-1 to 12 bar), the max. value is set to 12 bar

o21

MaxTransPres.

Pressure transmitter

The range of the pressure transmitter can be set by entering the

transmitter’s minimum value at address o20 and maximum value

at address o21. The pressure sensor input is set up by default to

accept an AKS 32R pressure transducer. If another sensor is to be

used, it is important to note that it needs to be a 5 V ratiometric

type (10%-90% of supply voltage).

The default range for the typical pressure transducer is 0 to 16 bar.

This can be changed by setting the minimum transducer pressure,

"o20 MinTransPres", and the maximum transducer pressure, "o21

MaxTransPres", to the new values.

Settings and checks to be made before

start

Basic settings

Before using the EKD 316 controller, there are settings that have to

be made for each individual application. These are the refrigerant

type, the pressure transducer range and the total number of steps

for the ETS valve.

It is good practice and in some cases necessary to set the Main

Switch r12 to OFF when making these changes.

If terminal 20-21 has been used as a start/stop regulation, then the

interaction between internal and external start/stop function is, as

shown on the following table:

Internal

Start/stop

External

start/stop (DI)

Regulation

Sensor

monitoring

Configuration

settings

Off

Off

=>

Off

No

Yes

Off

On

=>

Off

No

Yes

On

Off

=>

Off

Yes

No

On

On

=>

Yes

Yes

No

Refrigerant type

It is possible to choose from a list of 37 different refrigerants in the

controller.

If the refrigerant is not found on the list, it is possible to enter the

Antione constants for the unlisted refrigerant using MODBUS

communication and setting o30 to 13.

ETS valve type

It is important to select the right valve type as listed under Valve

definition. On using external display EKA 164A, the valve selection

will be displayed as 25, 50, 100, 250, 400, uSr, Sa9, 6 and CC.

The number of steps and steps/sec can also be set in the controller

at addresses n37 and n38 respectively:

In practise, the EKD 316 external display can only manage three

digits. Therefore the set value at address n37 is always 10 times

greater, i.e. if n37 is set to 263 then the true value is 2630. The same

applies to the n37 address in the MODBUS communication system.

Refrigerant setting

Before refrigeration can be started, the refrigerant must be defined.

You can select the following refrigerants:

o30

1 = R12

2 = R22

3 = R134a

4 = R502

5 = R717

6 = R13

7 = R13b1

8 = R23

9 = R500

10 = R503

11 = R114

12 = R142b

13 = User-defined

14 = R32

15 = R227

16 = R401

17 = R507

18 = R402A

19 = R404A

20 = R407C

21 = R407A

22 = R407B

23 = R410A

24 = R170

25 = R290

26 = R600

27 = R600a

28 = R744

29 = R1270

30 = R417A

31 = R422A

32 = R413A

33 = R422D

34 = 427A

35 = R438A

R36 = Opteon XP10

37 = R407F

(

Warning

: Wrong selection of refrigerant may cause damage to the compressor).

Start of controller

When the electric wires have been connected to the controller, the

following points have to be attended to before the regulation starts:

1. Switch off the external ON/OFF switch that starts and stops the

regulation.

2. Follow the menu survey in Appendix I, and set the various

parameters to the required values.

3. Switch on the external switch, and regulation will start.

4. Follow the actual superheat on the display.

Pressure Pe

MOP + 0.5

MOP

OD

At this pressure the OD

increases slower and

slower.

At this pressure the OD

no longer increases.

Beyond it the OD

decreases.