DMS Manual

■

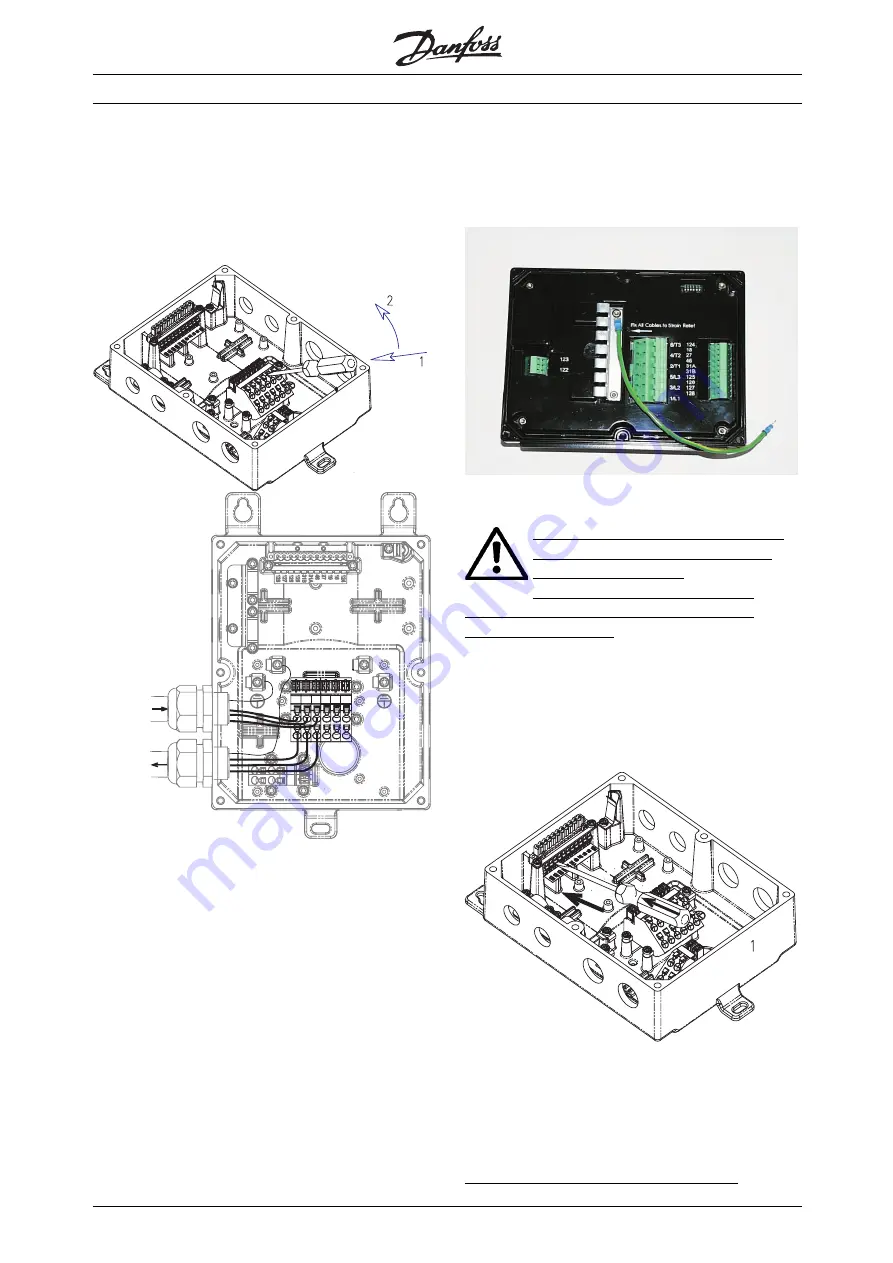

Power Wiring

Connect the Supply voltage to the DMS input

terminals 1/L1, 3/L2 & 5/L3.The terminals in the

Extended versions of the DMS allow two cables

to loop the power line as shown.

177ha011.10

Use of screw driver to open the connector clamp

3-phase Mains from

power-bus/

previous unit

3-phase Mains to

next unit

e77ha013.eps

Looping the power line - 3-phase mains

Connect the Motor terminals to the DMS output

terminals 2/T1, 4/T2 & 6/T3. Take care of the phase

sequence to have the correct direction of rotation.

The terminals in the Extended versions of the

DMS allow two cables to connect two motors

in parallel to one DMS.

Maximum cross section: 4 mm sq. (10 AWG)

For ST & SB versions, provide strain relief for power

and control cables by using the cable support

provided in the DMS unit, as shown.

■

Power factor correction

If a DMS is used with static power factor

correction it must be connected to the

supply side of the DMS.

Connecting power factor correction

capacitors to the output of the DMS will result

in damage to the DMS.

■

Control Wiring

Complete the Control wiring as shown in the

Electrical Schematic diagram.

177ha012.10

Use of a screw driver to open the connector clamp

for control terminals [Press to open the clamp]

Rev310103

Connect Control Supply / AS-i Interface at

the terminals provided.

Contacts used for controlling these inputs should be

low voltage, low current rated (Gold flash or similar)

Maximum cross section: 2.5 mm2 (12 AWG)

Use cables complying with local regulations.

MG.05.A2.02 - VLT is a registered Danfoss trademark

6