AKD 2800

■

Special conditions

■

Aggressive environments

As all other electronic equipment, a frequency

converter contains a number of mechanical and

electronic components, which to a varying extent

are vulnerable to environmental impact.

Consequently, the frequency converter is

not to be installed in environments, where

liquids, particles or gases are in the air that

would impact and damage the electronics. Unless the

necessary measures are taken to protect the frequency

converter, there is a risk of stoppages, which reduce

the service life of the frequency converter.

Liquids can be carried through the air and condense

in the frequency converter. In addition, liquids may

facilitate galvanic corrosion of components and metal

parts. Steam, oil and brine may cause corrosion of

components and metal parts. In these areas, it is

recommended to fit units in cabinets. As a minimum,

cabinets should be enclosure IP 54.

Particles in the air, such as dust particles, may lead

to mechanical, electrical and thermal faults on the

frequency converter. Typical indicators that there

are too many particles in the air are dust particles

around the frequency converter fan. In very dusty

areas, cabinet fitting of units is recommended. As a

minimum, cabinets should be enclosure IP 54.

Aggressive gases, such as sulphur, nitrogen and

chlorine compounds, together with high humidity and

temperature, facilitate possible chemical processes on

the components of the frequency converter. These

chemical processes quickly impact and damage

the electronics. In these areas, cabinet fitting with

fresh-air circulation in the cabinet is recommended,

thereby ensuring that aggressive gases are kept

away from the frequency converter.

NB!:

Fitting of frequency converters in aggressive

environments increases the risk of stoppages,

in addition to considerably reducing the

service life of the unit.

Before the frequency converter is installed, it must be

checked whether there are liquids, particles or gases

in the air. This can be done by looking at existing

installations in the same environment. Typical indicators

of harmful airborne liquids are water or oil on metal parts

or corrosion of metal parts. Too many dust particles are

typically observed on top of installation cabinets and on

existing electrical installations. Indicators that there are

aggressive gases in the air are copper rails and cable

ends that are black on existing electrical installations.

■

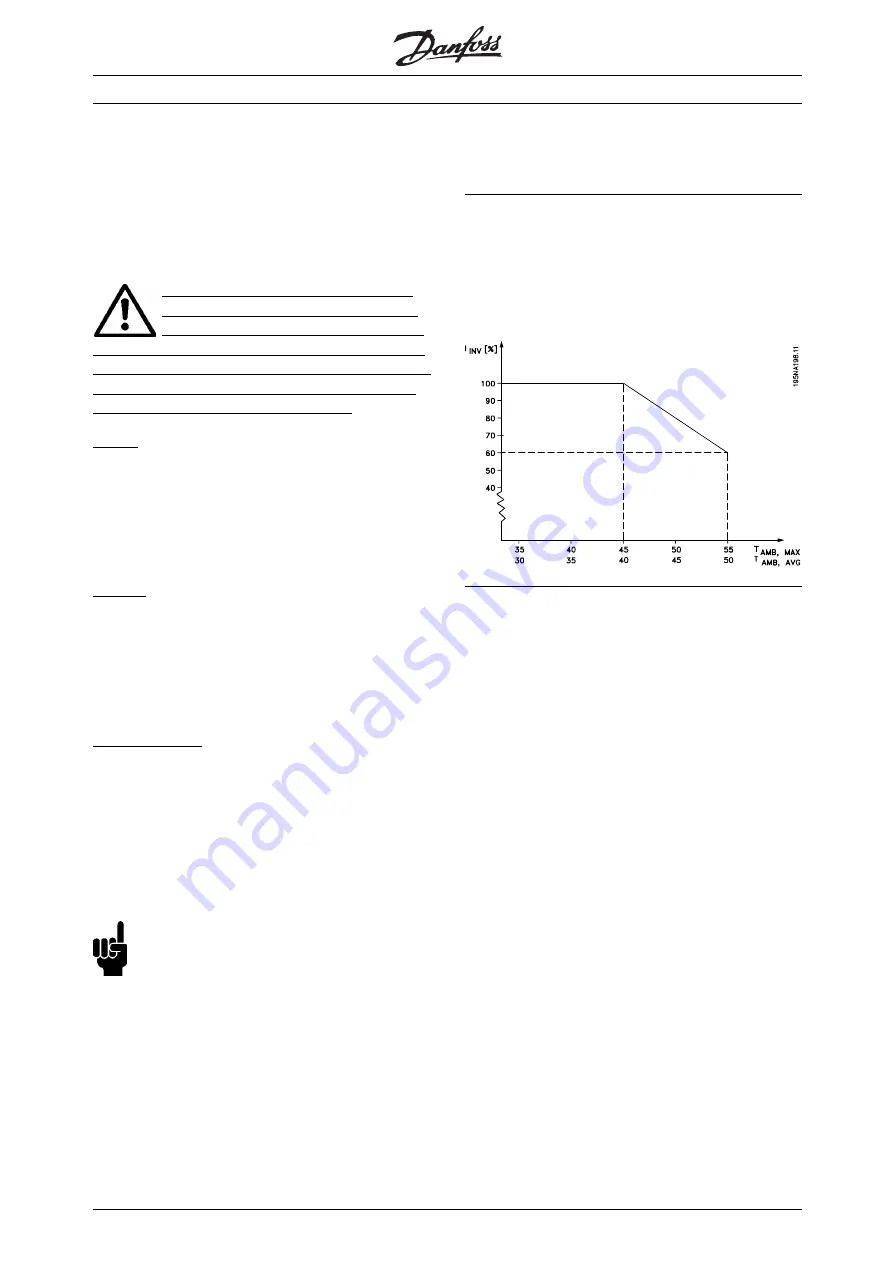

Derating for ambient temperature

The ambient temperature (T

AMB,MAX

) is the maximum

temperature allowed. The average (T

AMB,AVG

) measured

over 24 hours, must be at least 5 °C lower. If the

frequency converter operates at temperatures above 45

°C, a derating of the rated output current is necessary.

■

Galvanic Isolation (PELV)

PELV (Protective Extra Low Voltage) insulation is

achieved by inserting galvanic isolators between the

control circuits and circuits that are connected to the

mains potential. The frequency converter is designed

to meet the requirements for protective separation

by means of having the necessary creepage and

clearance distances. These requirements are described

in standard EN 50 178. It is also a requirement

that the installation is carried out as described in

local/national regulations regarding PELV.

All control terminals, terminals for serial communication

and relay terminals are safely separated from the

mains potential, i.e. they comply with the PELV

requirements. Circuits that are connected to control

terminals 12, 18, 19, 20, 27, 29, 33, 42, 46, 50,

53, 55 and 60 are galvanically connected to one

another. Serial communication connected to fieldbus

is galvanically insulated from the control terminals,

although this is only a functional insulation.

The relay contacts on terminals 1 - 3 are insulated

from the other control circuits with reinforced/double

isolation, i.e. PELV is observed for these, even though

there is mains potential at the relay terminals.

The circuit elements described below form the safe

electric separation. They fulfill the requirements

for reinforced/double insulation and associated

testing pursuant to EN 50 178.

MG.28.H2.02 -

62