EWAP400~540MBYNN

Packaged air-cooled water chillers

4PW22678-1B

Installation manual

4

A field supplied blow down port for flushing fluid and

accumulated material from inside the filter can be connected on

the filter end cap.

■

Connecting the counter pipes

Weld the supplied counter pipes to the ends of the water circuit

and connect to the unit with the provided

couplings.

2

Drain taps must be provided at all low points of the system to

permit complete drainage of the circuit during maintenance or in

case of shut down.

3

Air vents must be provided at all high points of the system. The

vents should be located at points which are easily accessible for

servicing.

4

Shut-off valves should be provided at the unit so that normal

servicing can be accomplished without draining the system.

5

Vibration eliminators in all water piping connected to the chiller

are recommended to avoid straining the piping and transmitting

vibration and noise.

6

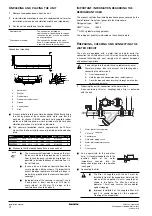

For units in a DICN configuration with common leaving water

control, be sure to foresee an insertion hole for the additional

water temperature sensor. Sensor and sensor holder are

optional parts.

The insertion hole shall be 1/4"GAS female thread and should

be located in the mixed waterflow of the chillers.

Make sure that the sensortip is in the waterflow and that you

have a length of straight pipe (L) of at least 5x the pipe diameter

(A) before the sensor.

Choose the position of insertion in a way that the cable length of

the sensor (12 m) is long enough to be attached to the master

PCB.

C

ONNECTING

THE

WATER

CIRCUIT

The evaporator is foreseen of flexible joints for the water inlet and

outlet (refer to the outlook diagram). Evaporator water connections

are to be made in accordance with the outlook diagram, respecting

the water in- and outlet.

If air or dust gets in the water circuit, problems may occur. Therefore,

always take into account the following when connecting the water

circuit:

1.

Use clean pipes only.

2.

Hold the pipe end downwards when removing burrs.

3.

Cover the pipe end when inserting it through a wall so that no dust

and dirt enter.

W

ATER

CHARGE

,

FLOW

AND

QUALITY

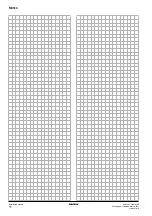

To assure proper operation of the unit, the water flow through the

evaporator must be within the operation range as specified in the

table below and a minimum water volume is required in the system.

The minimum water volume v [l] in the system should fullfill the

criteria below:

The water quality must be in accordance with the specifications listed

in the table below.

P

IPING

INSULATION

The complete water circuit, inclusive all piping, must be insulated to

prevent condensation and reduction of the cooling capacity.

Protect the water piping against water freezing during winter period

(e.g. by using a glycol solution or heatertape).

Minimum water flow

Maximum water flow

EWAP400

565 l/min

2265 l/min

EWAP460

670 l/min

2680 l/min

EWAP540

775 l/min

3100 l/min

Victaulic

®

ØA

L

≥

5 x ØA

>30m

m

>3

0m

m

69m

m

69

m

m

>30m

m

69m

m

v>(Q/2)xt/(Cx

∆

T)

Q

highest cooling capacity of the unit in lowest capacity step within

the range of application (kW)

t

antirecycling timer of unit (AREC)/2(s)=300 s

C

specific heat capacity of the fluidum (kJ/kg°C)=4.186 kJ/kg°C for

water

∆

T

temperature difference between starting and stopping of the

compressor.

∆

T=a+2b+c

(for designation of a, b and c, refer to the operation manual)

NOTE

For units in a DICN configuration, the minimum

required water volume in the system must equal the

biggest required minimum volume of every individual

chiller in the system.

circulating

water

supply

water

tendency if

out of criteria

Items to be controlled

pH

at 25°C

6.8~8.0

6.8~8.0

co

scale

Electrical conductivity

[mS/m]

at 25°C

<40

<30

co

scale

Chloride ion

[mg Cl

–

/l]

<50

<50

corrosion

Sulfate ion

[mg SO

4

2

–

/l]

<50

<50

corrosion

M-alkalinity (pH 4.8)

[mg CaCO

3

/l]

<50

<50

scale

Total hardness

[mg CaCO

3

/l]

<70

<70

scale

Calcium hardness

[mg CaCO

3

/l]

<50

<50

scale

Silica ion

[mg SiO

2

/l]

<30

<30

scale

Items to be referred to

Iron

[mg Fe/l]

<1.0

<0.3

cor

scale

Copper

[mg Cu/l]

<1.0

<0.1

corrosion

Sulfide ion

[mg S

2–

/l]

not

detectable

not

detectable

corrosion

Ammonium ion

[mg NH

4

+

/l]

<1.0

<0.1

corrosion

Remaining chloride

[mg Cl/l]

<0.3

<0.3

corrosion

Free carbide

[mg CO

2

/l]

<4.0

<4.0

corrosion

Stability index

—

—

cor

scale

The water pressure should not exceed the maximum

working pressure of 10 bar.

NOTE

Provide adequate safeguards in the water circuit to

make sure that the water pressure will never exceed

the maximum allowable working pressure.