8 Commissioning

Installation manual

31

ET9W

Daikin Altherma 3 H HT F

4P644730-1 – 2021.02

1

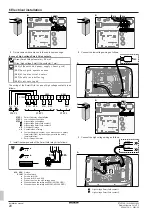

Check with the hydraulic configuration which space

heating loops can be closed by mechanical,

electronic, or other valves.

—

2

Close all space heating loops that can be closed

(see previous step).

—

3

Create a thermo request on the main zone only.

—

4

Wait 1 minute until the unit is stabilized.

—

5

If the additional pump is still assisting (the green

LED on the right hand sided pump is ON) increase

the flow until the additional pump is not assisting

anymore (LED is OFF).

—

6

Go to [8.4.A]:

Information

>

Sensors

>

Flow

rate

.

7

Read out the flow rate and modify the bypass valve

setting to reach the minimum required flow rate + 2 l/

min.

—

Minimum required flow rate

25 l/min

8.2.2

To perform an air purge

1

Set the user permission level to Installer. See

change the user permission level"

—

2

Go to [A.3]:

Commissioning

>

Air purge

.

3

Select

OK

to confirm.

Result:

The air purge starts. It stops automatically

when air purge cycle is finished.

To stop the air purge manually:

—

1

Go to

Stop air purge

.

2

Select

OK

to confirm.

INFORMATION

When air purging in automatic mode, the first air purge is

always for the main zone, the second started air purge is

always for the additional zone. To air purge the domestic

hot water tank circuit, choose [A.3.1.5.2]

Circuit

=

Tank

at

the start of the manual air purge of the main zone or

additional zone.

8.2.3

To perform an operation test run

INFORMATION

The test run only applies to the additional temperature

zone.

1

Set the user permission level to

Installer

change the user permission level"

—

2

Go to [A.1]:

Commissioning

>

Operation test

run

.

3

Select a test from the list.

Example:

Heating

.

4

Select

OK

to confirm.

Result:

The test run starts. It stops automatically

when ready (±30 min).

To stop the test run manually:

—

1

In the menu, go to

Stop test run

.

2

Select

OK

to confirm.

INFORMATION

If the outdoor temperature is outside the range of

operation, the unit may NOT operate or may NOT deliver

the required capacity.

To monitor leaving water and tank temperatures

During test run, the correct operation of the unit can be checked by

monitoring its leaving water temperature (heating/cooling mode) and

tank temperature (domestic hot water mode).

To monitor the temperatures:

1

In the menu, go to

Sensors

.

2

Select the temperature information.

8.2.4

To perform an actuator test run

Purpose

Perform an actuator test run to confirm the operation of the different

actuators. For example, when you select

Pump

, a test run of the

pump will start.

1

Set the user permission level to Installer. See

change the user permission level"

21].

—

2

Go to [A.2]:

Commissioning

>

Actuator test run

.

3

Select a test from the list.

Example:

Pump

.

4

Select

OK

to confirm.

Result:

The actuator test run starts. It stops

automatically when ready (±30 min).

To stop the test run manually:

—

1

In the menu, go to

Stop test run

.

2

Select

OK

to confirm.

Possible actuator test runs

▪

Backup heater 1

test

▪

Backup heater 2

test

▪

Pump

test

INFORMATION

Make sure that all air is purged before executing the test

run. Also avoid disturbances in the water circuit during the

test run.

▪

Shut off valve

test

▪

Diverter valve

test (3-way valve for switching between space

heating and tank heating)

▪

Bivalent signal

test

▪

Alarm output

test

▪

C/H signal

test

▪

DHW pump

test

▪

Bizone kit direct pump

test (bizone kit EKMIKPOA or

EKMIKPHA)

▪

Bizone kit mixed pump

test (bizone kit EKMIKPOA or

EKMIKPHA)

▪

Bizone kit mixing valve

test (bizone kit EKMIKPOA or

EKMIKPHA)

8.2.5

To perform an underfloor heating screed

dryout

1

Set the user permission level to Installer. See

change the user permission level"

21].

—

2

Go to [A.4]:

Commissioning

>

UFH screed dryout

.

3

Set a dryout program: go to

Program

and use the

UFH screed dryout programming screen.

4

Select the zone where you want to perform the UFH

screed dryout program: go to the

Zone selection

screen.