4 Installation

Installation manual

9

EABH/9W

Daikin Altherma 3 H W

4P644479-1 – 2020.12

If…

Then…

The system does NOT contain a

domestic hot water tank

You can use either propylene

glycol

(a)

or ethylene glycol

(a)

Propylene glycol, including the necessary inhibitors, classified as

Category III according to EN1717.

Required concentration of glycol

The required concentration of glycol depends on the lowest

expected outdoor temperature, and on whether you want to protect

the system from bursting or from freezing. To prevent the system

from freezing, more glycol is required.

Add glycol according to the table below.

Lowest expected

outdoor

temperature

Prevent from

bursting

Prevent from

freezing

–5°C

10%

15%

–10°C

15%

25%

–15°C

20%

35%

–20°C

25%

—

–25°C

30%

—

–30°C

35%

—

INFORMATION

▪ Protection against bursting: the glycol will prevent the

piping from bursting, but NOT the liquid inside the

piping from freezing.

▪ Protection against freezing: the glycol will prevent the

liquid inside the piping from freezing.

NOTICE

▪ The required concentration might differ depending on

the type of glycol. ALWAYS compare the requirements

from the table above with the specifications provided by

the glycol manufacturer. If necessary, meet the

requirements set by the glycol manufacturer.

▪ The added concentration of glycol should NEVER

exceed 35%.

▪ If the liquid in the system is frozen, the pump will NOT

be able to start. Mind that if you only prevent the

system from bursting, the liquid inside might still freeze.

▪ When water is at standstill inside the system, the

system is very likely to freeze and get damaged.

Glycol and the maximum allowed water volume

Adding glycol to the water circuit reduces the maximum allowed

water volume of the system. For more information, see the installer

reference guide (topic "To check the water volume and flow rate").

Glycol setting

NOTICE

If glycol is present in the system, setting [E-0D] must be

set to 1. If the glycol setting is NOT set correctly, the liquid

inside the piping can freeze.

Freeze protection by freeze protection valves

About freeze protection valves

When no glycol is added to the water, you can use freeze protection

valves to drain the water from the system before it can freeze.

▪ Install freeze protection valves (field supply) at all lowest points of

the field piping.

▪ Normally closed valves (located indoors near the piping entry/exit

points) can prevent that all water from indoor piping is drained

when the freeze protection valves open.

NOTICE

When freeze protection valves are installed, set the

minimum cooling setpoint (default=8°C) at least 2°C higher

than the maximum opening temperature of the freeze

protection valve. If lower, freeze protection valves can

open during cooling operation.

For more information, see the installer reference guide.

Heater tape (field supply)

1

Install heater tape to the outdoor field piping.

2

Provide external power supply for the heater tape.

NOTICE

▪ For the internal heater tape to operate, the power to the

unit MUST be ON. For this reason, during cold periods,

never disconnect the power, nor turn off the main

switch.

▪ In case of a power failure, power to the heater tape

(both internal and external) will be aborted and the

water circuit will NOT be protected. To guarantee a full

protection, it is always possible to add glycol to the

water circuit or to use freeze protection valves, even

when installing heater tape to the outdoor field piping.

4.3.4

To fill the domestic hot water tank

See the installation manual of the domestic hot water tank.

4.3.5

To insulate the water piping

The piping in the complete water circuit MUST be insulated to

prevent condensation during cooling operation and reduction of the

heating and cooling capacity.

Outdoor water piping insulation

See the installation manual of the outdoor unit, or the installer

reference guide.

4.4

Connecting the electrical wiring

DANGER: RISK OF ELECTROCUTION

WARNING

ALWAYS use multicore cable for power supply cables.

4.4.1

About electrical compliance

Only for the backup heater of the indoor unit

See

"To connect the backup heater power supply"

11].

4.4.2

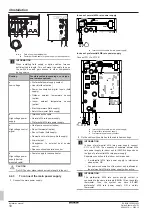

To connect the electrical wiring to the

indoor unit

1

Open the switch box so that you can access the back of the

switch box. See

2

Route the wiring as follows:

▪ Enter the unit from the bottom.

▪ Route the wiring via the back of the switch box.

▪ Fix the cables with cable ties to the cable tie mountings at

the back of the switch box.