3 Preparation

Installation manual

5

EABH/9W

Daikin Altherma 3 H W

4P644479-1 – 2020.12

3.2.1

To check the water volume and flow rate

Minimum water volume

Check that the total water volume in the installation is minimum 20

litres, the internal water volume of the outdoor unit NOT included.

NOTICE

When circulation in each space heating/cooling loop is

controlled by remotely controlled valves, it is important that

the minimum water volume is guaranteed, even if all of the

valves are closed.

Minimum flow rate

Check that the minimum flow rate in the installation is guaranteed in

all conditions. This minimum flow rate is required during defrost/

backup heater operation. For this purpose, use the overpressure

bypass valve delivered with the unit, and respect the minimum water

volume.

Minimum required flow rate

20 l/min

NOTICE

To guarantee proper operation it is recommended to have

a minimum flow of 28 l/min during DHW.

NOTICE

If glycol was added to the water circuit, and the

temperature of the water circuit is low, the flow rate will

NOT be displayed on the user interface. In this case, the

minimum flow rate can be checked by way of the pump

test (check that the user interface does NOT display error

7H).

NOTICE

When circulation in each or certain space heating loops is

controlled by remotely controlled valves, it is important that

the minimum flow rate is guaranteed, even if all valves are

closed. In case the minimum flow rate cannot be reached,

a flow error 7H will be generated (no heating or operation).

See the installer reference guide for more information.

See the recommended procedure as described in

22].

3.2.2

Third-party tank requirements

In case of a third-party tank, the tank shall adhere to the following

requirements:

▪ The heat exchanger coil of the tank is ≥1.05 m².

▪ The tank thermistor must be located above the heat exchanger

coil.

▪ The booster heater must be located above the heat exchanger

coil.

NOTICE

Performance.

Performance data for third-party tanks

CANNOT be provided, and performance CANNOT be

guaranteed.

NOTICE

Configuration.

Configuration of a third-party tank depends

on the size of the heat exchanger coil of the tank. For more

information, see the installer reference guide.

3.3

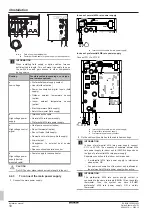

Preparing electrical wiring

3.3.1

Overview of electrical connections for

external and internal actuators

Item

Description

Wires

Maximum

running

current

Outdoor unit and indoor unit power supply

1

Power supply for

outdoor unit

2+GND

(a)

2

Power supply and

interconnection cable to

indoor unit

3

(g)

3

Power supply for

backup heater

See table below. —

4

Preferential kWh rate

power supply (voltage

free contact)

2

(e)

5

Normal kWh rate power

supply

2

6.3 A

Optional equipment

6

3‑way valve

3

100 mA

(b)

7

Power supply for

booster heater and

thermal protection

(from indoor unit)

4+GND

(c)

8

Power supply for

booster heater (to

indoor unit)

2+GND

13 A

9

Domestic hot water

tank thermistor

2

(d)

10

User interface used as

room thermostat

2

(f)

11

Room thermostat

3 or 4

100 mA

(b)

12

Outdoor ambient

temperature sensor

2

(b)

13

Indoor ambient

temperature sensor

2

(b)

14

Heat pump convector

2

100 mA

(b)

Field supplied components

15

Shut-off valve

2

100 mA

(b)

16

Electricity meter

2 (per meter)

(b)

17

Domestic hot water

pump

2

(b)

18

Alarm output

2

(b)

19

Changeover to external

heat source control

2

(b)

20

Space cool/heat

operation control

2

(b)

21

Power consumption

digital inputs

2 (per input

signal)

(b)

22

Safety thermostat

2

(e)

(a)

Refer to name plate on outdoor unit.

(b)

Minimum cable section 0.75 mm².

(c)

Cable section 2.5 mm².

(d)

The thermistor and connection wire (12 m) are delivered

with the domestic hot water tank.

(e)

Cable section 0.75 mm² till 1.25 mm²; maximum length:

50 m. Voltage-free contact shall ensure the minimum

applicable load of 15 V DC, 10 mA.

(f)

Cable section 0.75 mm² till 1.25 mm²; maximum length:

500 m. Applicable for both single user interface and dual

user interface connection.

(g)

Cable section 1.5 mm².