EN

2

ATTENTION! Follow all safety precautions and instructions as outlined in this manual in its

entirety. If any portion of this manual is not completely understood, please contact an authorized

service dealer near you for installation, starting, operating and servicing procedures or contact us at

No.. Common sense and strict compliance with these special instructions while performing service

are essential to preventing accidents.

For professional advice on this product and its operating requirements, please contact a dealer near

you or contact us directly at the information provided below. If you have any questions or sugges-

tions, please contact us any time between 8:00 AM and 5:00 PM.

Warning Announcements!

Because this generator can be used as a single fuel or multi-fuel unit, pay close attention to factory

settings. This unit can run on natural gas (NG) or propane (LPG).

Please pay attention to all factory settings! Unit comes already preset to one fuel or the other.

Before starting generator

:

●

Read the user manual carefully and operate generator according to factory recommendations.

●

If you do not operate according to the instructions, it can cause personal injury or loss of life.

Tips and Warning Labels

Warning, Danger and Attention labels are provided to indicate the possibility of damage and perso-

nal injury when using generator. In addition, this information can indicate what kind of damage you

could experience.

If you don’t follow the operational requirements, it could result in damage to the engine or rela-

ted generator equipment.

If you don’t follow the instructions of the operating requirements, it could result in personal

injury or other equipment damage.

If you don’t follow the instructions closely outlined in the operating requirements, it could result

in serious injury or loss of life.

Users must operate in accordance with all requirements; otherwise it could damage the engine and

genset.

This manual contains the following International ISO Graphical Symbols:

Nota

Save These Instructions – The manufacture suggest that these rules for safe operation be copied

and posted in potential hazard areas. Safety should be stressed to all operators, potential operators

and service technicians for this equipment.

Nota

Save These Instructions – This manual contains important instructions that should be followed

during installation and maintenance of the generator and battery.

1. TECHNICAL FEATURES

I. Technical Features of the Single Phase Dual-Fuel Generator

This gas generator is Dual-fuel and able to utilize both Natural Gas (NG) and Liquid Propane (LPG). It

is a versatile multi-fuel engine. Based on our standards, we have designed this unit to operate in an

environmentally safe and user friendly manor:

1. Speed Regulating System: This gas generator uses an internally designed electronic speed con-

trol system, allowing for quick and easy adjustments to the engine speed that can be set to specific

speed ranges. This control system allows the engine to run more smoothly and respond quickly to

sudden increases or decreases in required engine speed.

2. Silent Air In-take System: Extra-large air intake cross-sections in the housing enclosure ensures

ample air flow for the engine and air in-take. This unique housing enclosure structure leads to a

significant reduction operating noise.

3. Large Liquid Cooled Radiator and Reservoir: The use of an over-sized radiator and coolant reser-

voir, like those used in automobile engines, allows for additional radiator coil surface and helps

maintain a more ambient and stable engine temperature even in the hottest climates. Utilizing this

liquid cooled system adds to the life and long term operating dependability of your gas generator

investment.

4. Automatic Transfer Switch (ATS) and Function: Automatic Transfer Switches are critical compo-

nents of any emergency or standby power system. They are used for transferring essential loads

and electrical distribution from one power source to another automatically, without personal involve-

ment.

5. Intelligent Hazard Control System and Function: The Intelligent Hazard Control System warns of

dangerous conditions that exist to the engine or generator. This system continually checks and

monitors the unit’s operating conditions and will automatically shut down if detected, to help avoid

costly damage. This system uses a visual control panel that can be preset according to the user's

needs.

Important Safety Instructions

SAVE THESE INSTRUCTIONS – This manual contains important instructions for the following

models BNL20SE single-phase and BNL20SE-3 three-phase units that should be followed comple-

tely during installation and maintenance of the generator and battery.

I. Warnings

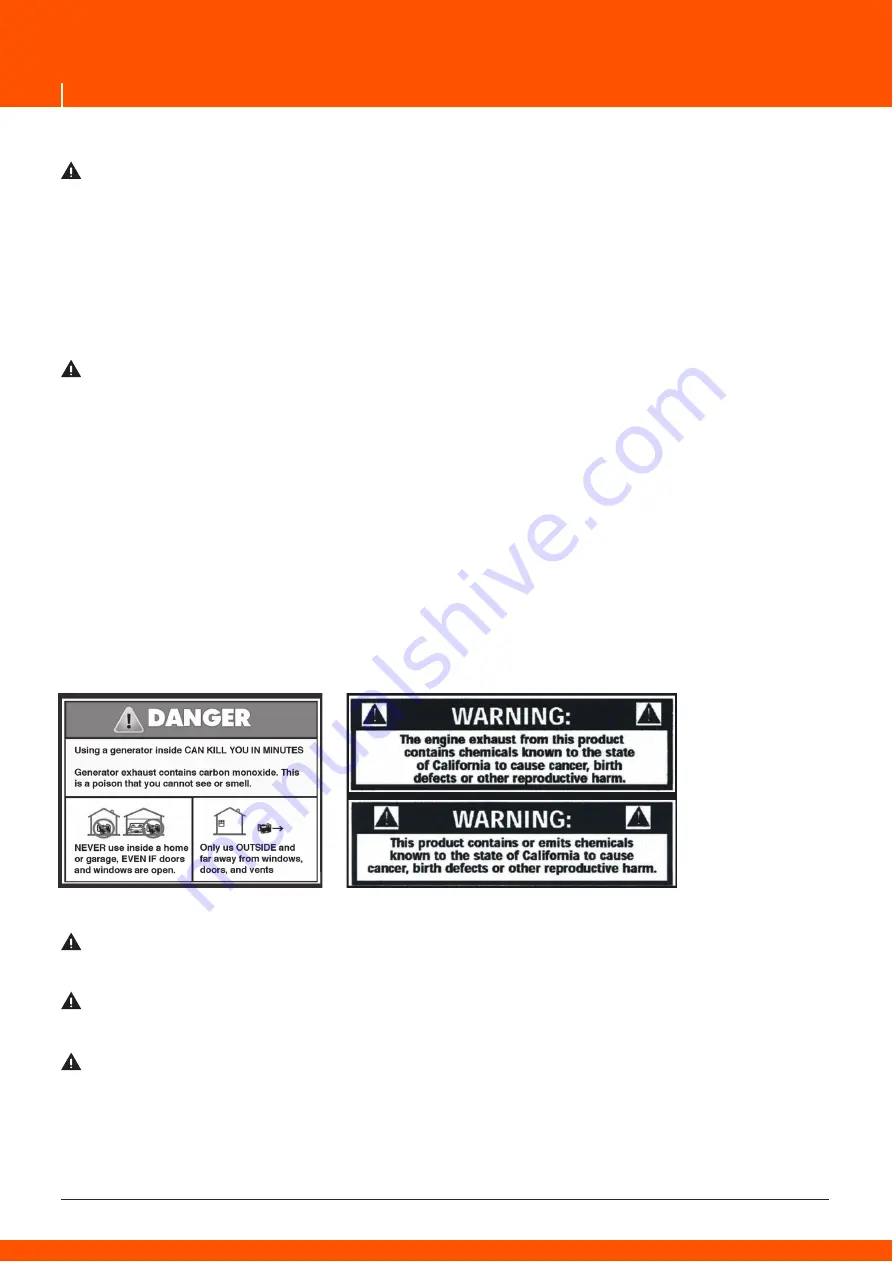

1. Generator Set Operation. Carbon monoxide can cause severe nausea, fainting, or even death.

Carbon monoxide is an odorless, colorless, tasteless, nonirritating gas that can cause death if

inhaled for even a short time. Avoid breathing exhaust fumes when working on or near the generator

set. Never operate the generator set inside a building. Never operate the generator set where

exhaust gas could seep inside or be drawn into a potentially occupied building through windows, air

intake vents, or other openings.

N'employezjamais à l'intérieurd'unemaisonou d'un garage, MÊME SI les portes et les fenêtresson-

touvertes.

Employezseulement EN DEHORS et loin des fenêtresouvertes, des portes, et des passages.

Risquetoxique de vapeurs. Les moteurs courants dégagent le carbone oxyde, un gaztoxiqueinodore

qui peut causer la nausée, l'évanouissement, ou la mort. Ne mettez pas enmarcheou ne courez pas

le moteur à l'intérieuroudans un secteurinclus, mêmesi les fenêtres et les portessontouvertes.

2. Fuel System. Fuel Vapors are highly explosive and can cause severe injury or death. Use extreme

care when handling and storing fuels. Store fuels in a well-ventilated area away from spark-produ-

cing equipment, gas hot water heaters and out of the reach of children. Never add fuel while the

engine is running or hot, fuel spills may ignite on contact with hot parts and muffler. Do not smoke

or operate around sparks or open flames. Keep fuel lines and connections tight and in good working

condition.

3. Servicing the Exhaust System. Hot parts can cause severe injury. Do not touch hot engine parts.

The engine and exhaust system components become extremely hot during operation.

4. Servicing the Engine. Hot parts can cause personal injury or property damage. Install (optional

feature, sold separately) engine block heater for extreme cold weather before connecting it to power

(See separate installation instructions). Operating the engine block heater before installation can

cause burns and component damage. Disconnect power to the engine block heater and allow it to

cool before servicing the heater or nearby parts. Keep the generator at least 2m

(

6ft

)

distance from

other devices.

Grounding Generator

5. Grounding Electrical Equipment Hazardous voltage can cause severe injury or death. Electrocu-

tion is possible whenever electricity is present. Ensure you comply with all applicable state and local

codes and standards. Electrically ground the generator set, transfer switch, and related equipment

and electrical circuits. Turn off the main circuit breakers of all power sources before servicing the

equipment. Never contact electrical leads or appliances when standing in water or on wet ground

because these conditions increase the risk of electrocution. It is highly recommended that a barrier

exist between you and the ground surface. We recommend using a wooden pallet with rubber mat

on top to stand on while working or servicing the standby generator.

Grounding is required of all AC circuits, use terminal (identify terminal)for bonding this circuit to the

enclosure with a grounding rod (Not provided with unit). Ground the enclosure to a grounding elec-

trode in accordance with state and local code requirements

6. Gas Vapors and Fuel Leaks. Explosive fuel vapors can cause severe injury or death. Fuel leaks

can cause an explosion. Use digital gas leak detector on all gas connections for no less than 1

minuet per connection. Leak detector not included with generator. Contact Service provider.

7. Engine Noise. Hazardous noise can cause hearing loss. Generator sets not equipped with sound

enclosures can produce noise levels greater than 105 dB. Prolonged exposure to noise levels grea-

ter than 85 dB can cause permanent hearing loss! Wear hearing protection at all times when wor-

king near an operating generator set.

8. Short Circuits. Hazardous voltage/current can cause severe injury or death. Short circuits can

cause bodily injury and/or equipment damage. Do not connect electrical contacts with tools or while

wearing jewelry when making adjustments or repairs. Remove all jewelry before servicing the equip-

ment.

Electrical back-feed through the utility power supply can cause severe injury or death. You must

install a manual or automatic transfer switch on all standby power applications and installations.

This is to prevent the back-feeding of electrical current through power lines causing fire, severe

injury or death to utility personnel working on power lines.

9. Moving Parts. When the generator set is in operation, the cooling fan is rotating. Do not open the

maintenance cover and make adjustment while generator is running. Please shut down the engine

and turn electrical breaker in off position before maintenance or operation. Before restarting, close

all service panels.

10. Caution: for standby electrical output, connect generator to suitably rated transfer switch in

accordance with the canadian.

Electrical code, part i. this unit requires a 200amp transfer switch.

Attention: pour l’alimentation de réserve, connecter la sortie de la génératrice à un commutateur de

calibre approprié conformément au code canadien de l’électricité, première partie.

11. TThere is a permanent conductor between the generator (stator winding) and the frame.

il y a un conducteur permanent entre la génératrice (enroulement du stator) et le cadre.

II. Operating System Functions and Definitions

Depending on the generator unit model, control button functions may vary significantly. Refer to the

following functions:

1. Operating System

Power Switch

:

Function

:

The power switch controls the entire generator set control system. If this switch is placed

in the OFF (O push in down mode) position, the internal electrical control circuit of the unit will not

have any electrical power. When this switch is placed in the ON (I in the up mode) position, the

control system can be automatically started with ATS, tested and run.

Fuel Switch

:

Function

:

The fuel switch allows the fuel to flow to the engine when placed in the ON or ( I ) is in the

up position. Likewise, the switch turns the flow of fuel off to the engine when placed in the OFF (O)

push down position.

Emergency Stop Switch:

Function

:

The photo above shows Emergency Stop Switch on outside corner of unit.

Locate on the side corner of generator. When depressed, all generator control systems will imme-

diately shut down, including the engine and generator head. The Emergency Stop Switch should be

pressed immediately should any unexpected emergencies occur. Depressing this button will help

minimize dangerous damage to persons, pets, property, plants, or to the generator unit itself.

Use

:

When an emergency situation occurs, immediately press the Emergency Stop Switch. The unit

will automatically shut down. Once the switch has been depressed and the emergency situation has

passed, to re-start the generator unit, rotate clockwise 90 ° to pop up into the normal operational

position.

Circuit Breaker:

Function

:

The circuit breaker controls the ON/OFF functions of the generators electrical power

output. When this switch is in the up (ON) position, electrical power output will be produced and

flow normally. When this switch is placed in the down (OFF) position, electrical power output will be

broken, or turned off. However, as a safety function, when this switch is placed in the ON position,

the production of a too large of an electrical load or a short circuit due to faulty operation, the

switch will immediately and automatically switch to the OFF position in order to protect the genera-

tor from damage. Should this occur, turn off the generator unit and correct the cause before restar-

ting and placing the circuit breaker in the ON position.

Use

:

When starting manually, always start the generator before placing the circuit breaker in the ON

position. Likewise, when operating manually, place the circuit breaker in the OFF position before

shutting the generator down.

III. Engine Pre-start and Preparation

All necessary installation and maintenance must be conducted and performed by authorized licen-

sed personnel.

Before starting engine for the first time, engine oil and radiator coolant must be added. An initial

fluid inspection and pre-check is recommended before starting genset for the first time or when unit

has been in operation for over 20 hours. It can also be used as a quick review of all fluids. Check all

of the following items before running system for the first time.

I

MPORTANT NOTE!

Unit is not shipped with engine oil or coolant from Factory!!

After installment of generator, fill engine with recommended oil weight based on ambient temperatu-

re shown below and add radiator coolant. Prior to initial start-up, replace all service panels and

close lid. Start engine and allow 10 minutes for system to warm-up. After this has been performed

remove service panels rise lid and check for any leaks or drips. If found, tighten lose hoses, clamps

or plugs. Recheck all fluid levels and top off as necessary.

1. Engine Oil. The unit is not shipped with oil from factory!!! Use high-quality detergent oil “Classified

for Service in CC, SD, SE, or SF use” Only use oil having the following SAE viscosity ratings. Fill with

the recommended amount of oil as specified. Overfilling or under filling can cause damage to the

engine. Use the following recommended or similar type engine oil.

Temperature

Recommended Oil Grade

Below 32° F (0° C)

SAE 10W or 15W-40

32° to 80° F (-1° to 27° C) SAE 20W or 15W-40

Above 80° F (27° C) SAE 30W or 15W-40

-

Place funnel in engine oil inlet.

-

First time operation will require 4 liters or (4.25qts) of oil.

-

Check oil gauge dipstick regularly, oil level should be kept between top and bottom lines, at all

times. It is preferred to be at the top mark but not over.

2. Cooling System

Use only automotive grade antifreeze and distilled water in cooling system.

Do not use water that contains salt or alkalis (Tap Water)! Using non-distilled water creates scale in

the radiator causing corrosion and premature wear.

3. Fuel Conversion

Do not touch hot engine parts. The engine and exhaust system components become extremely hot

during operation.

Two fuel connections on the fuel block allow field conversion between natural gas (NG) and Liquid

Propane (LPG). The fuel metering valves are factory-set and sealed to provide the best possible hot

and cold starting.

Use the following procedure to convert fuel from one type to another:

Natural Gas (NG) and Liquid Propane (LPG) Conversion

-

Use a pressure reducing valve to reduce LP pressure supply.

-

Pushing the button as attached pictures below to the natural gas or LP vapor per the fuel which

you want to use.

Summary of Contents for DAPD15REG-EB

Page 1: ...DAPD REG EB www daewoopowerproducts com Gas generator USER S MANUAL...

Page 39: ...39 EN Three Phase ATS Wiring Diagram...

Page 40: ...40 Controller Wiring Diagram...

Page 61: ...61 8 SPARE PARTS LIST...

Page 62: ...62 EN...

Page 63: ...63...

Page 64: ...64 EN...

Page 65: ...65...

Page 66: ...66 EN...

Page 68: ...PR...

Page 69: ...NG LPG ISO...

Page 70: ...PR NG LPG ATS BNL SE BNL SE I...

Page 71: ...35...

Page 72: ...AC...

Page 73: ...35 ON OFF OFF CC SD SE SF SAE F C SAE W or W F to C SAE W or W F C SAE W or W...

Page 74: ...qts NG LPG LP LP...

Page 75: ...35 A LP ATS...

Page 76: ...ATS...

Page 77: ...35...

Page 78: ...OFF x...

Page 79: ...PR x NG LPG x API SE SP SG...

Page 80: ...x x x x x A B B A B...

Page 81: ...PR x...

Page 82: ...FULL...

Page 83: ...PR kgf lbs LCD...

Page 84: ...CFR I...

Page 85: ...PR AUTO OFF MANUAL ABC...

Page 86: ...NG LPG ETL ATS ETL AC NEC NEC AFCI...

Page 87: ...PR...

Page 88: ......

Page 89: ...PR F C SAE W W F C SAE W W F C SAE W W qts...

Page 90: ...LPG NG NG LPG LPG LP LPG NG LPG NG...

Page 91: ...35 LP AGA LP UL Listed AGA...

Page 92: ......

Page 93: ...35...

Page 94: ......

Page 95: ...35 GND GND AC ATS AC AWG...

Page 96: ...Controller O AUTO LED Close Gen...

Page 97: ...35 WTH STOP by cool LCD XX s LCD LCD Safety On LCD...

Page 98: ...Fail to stop LCD AWG AWG AWG AWG AWG AWG...

Page 99: ...35 DC AC AC DC...

Page 100: ...ATS...

Page 101: ...35 Three Phase ATS Wiring Diagram...

Page 102: ......

Page 105: ...35 ATS UL EZ...

Page 106: ...ATS EZ AC ATS...

Page 107: ...35 ATS OFF AUTO ON ON...

Page 108: ...x x x x ATS GND GND AC ATS AC AWG...

Page 109: ...35 NFPA E...

Page 110: ...MANUAL ATS BNL SE OFF OFF ON ATS AUTO ON...

Page 111: ...35 A B N M N M...

Page 112: ...B B...

Page 113: ...35 FULL...

Page 114: ......

Page 118: ......

Page 119: ...EN AC AVR 35...

Page 121: ...EN HSC IP ft M dB A PET NG m hr LPG kg hr NG kPa LPG kPa mm mm kg kg...

Page 122: ......

Page 123: ......

Page 124: ...35...

Page 125: ......

Page 126: ...35...

Page 127: ......

Page 128: ...ration Korea...