12/2008 - Art. Nr. 4200 1013 9300A

36

Maintenance

Maintenance works

Important

The burner should be serviced at least

once a year by a qualified specialist.

• Turn off the power supply at the all

pole switch.

• Check the absence of voltage.

• Close the fuel valve.

The setting values are indicated in the

paragraph entitled

“start-up”

Use only original parts.

• Remove the burner housing.

Cleaning

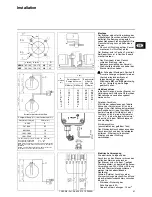

Shared access to the base plate

• Loosen the four plate mounting screws

on the housing by five turns.

• Dislodge the base plate and pull it

towards you until it is completely

released from the nozzle line.

• Hook the plate on the housing; there

are two options (see photos).

Dismantling the blast-tube

• Disconnect the power supply

connector.

• Unscrew the clamp screw.

• Remove the burner and place it on the

ground.

• Loosen the four screws for the

connecting nozzle by two turns and

remove the connecting nozzle.

• Replace, index and secure the

connecting nozzle.

• Reassemble all parts in the reverse

sequence to disassembly.

• Check the position of the hoses.

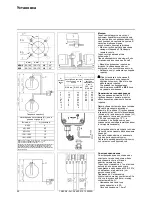

Cleaning the pump filter

The filter is located inside the pump

housing. It must be cleaned as part of

any maintenance work.

• Close the fuel oil intake valve.

• Place a container under the pump to

collect the fuel oil.

• Remove the screws and cover.

• Pull out the filter, clean or replace.

• Refit the filter and the cover using a

new seal.

• Screw down firmly.

• Open the fuel valve.

• Check it is airtight.

Cleaning the cover

• Clean the cover with a water and

detergent mixture. Do not use

chlorine-based or abrasive cleaning

products.

Note:

After each operation:

• Check the combustion parameters

under actual operating conditions

(doors closed, cover in place etc.),

and test the various circuits.

• Record the results in the relevant

documents.

Air box

• Remove the screw

K

.

• Remove the air box

• Remove any dust with a

dry

brush.

• Reassemble.

Combustion components

• Disconnect the ignition cables on the

electrodes.

• Remove and clean, or replace the

electrodes.

• Remove and clean the turbulator.

• Remove and replace the nozzle, using

the two wrenches (one to hold the

nozzle holder steady).

• Reassemble.

• Check the settings.

Volute

• Use a brush to remove dust from the

inside of the volute, the blower, the

connecting nozzle and the air flap.

Blower turbine setting

If the motor or the blower turbine are

replaced, the dimension

0

between

A

and

B

must be respected (see diagram).

• Tighten the turbine. Check that there is

no friction.

• Refit the base plate assembly on the

housing.

• Tighten the four screws in a cross

formation.

• Check the joints.

Cleaning the cell

• Remove the cell and wipe it with a dry,

clean cloth.

• Reassemble the cell.

Summary of Contents for NC4

Page 52: ...12 2008 Art Nr 4200 1013 9300A 52 R 1 2 9 BP1 BP1 B 2 BP2 R A4...

Page 54: ...12 2008 Art Nr 4200 1013 9300A 54 K 0 A B...

Page 55: ...12 2008 Art Nr 4200 1013 9300A 55 BP1 c 400...

Page 57: ...12 2008 Art Nr 4200 1013 9300A 57...

Page 58: ...12 2008 Art Nr 4200 1013 9300A 58...