16

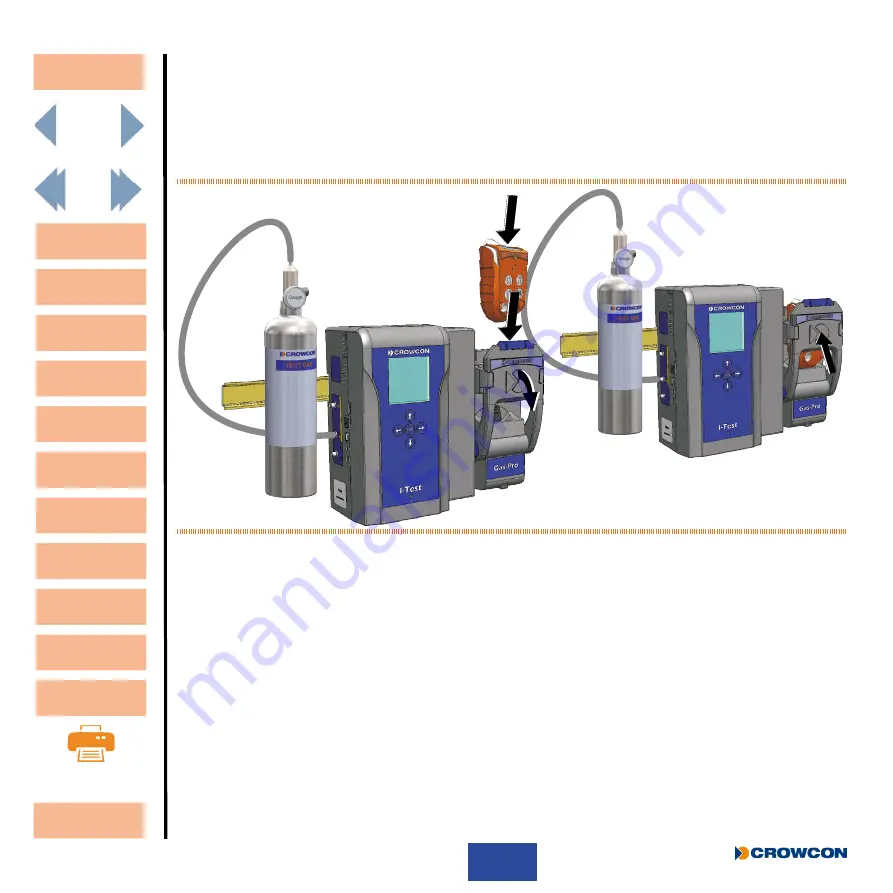

2.2 Loading a monitor into an I-Test

i

Before inserting the gas monitor ensure it is not in fault mode.

Turn the gas monitor on, wait for it to finish the start up process and then press the release button

À

, lower the module’s front flap

Á

, place the gas monitor into it’s holder

Â

and close the front flap

Ã

(see below):

Figure 6: Opening the I-Test

i

Once I-Test has been configured to carry out a test or sequence of test (e.g. bump test or

calibration) this will start as soon as the door is closed.

Do not remove the gas monitor from I-Test until the test sequence has completely finished.

The gas monitor audible alarm will be muted for the duration of the test, at the end of the

test the audible alarm will be reinstated.

Once a test has completed allow the monitor sensors to recover to ambient levels before

a retest. Failure to do so may cause the monitor be tested/calibrated incorrectly.

The first gas test after a prolonged period of inactivity may not be successful as I-Test will

need to be primed with the test gas, the test should be repeated.

!

Gas cylinders must be used with demand flow regulators.

À

Á

Â

Ã

Contents

Exit

Unpacking

Set-up

Operating I-Test

I-Test

Manager

Configuring

I-Test

Warranty

Overview

Contacts

Appendices

Troubleshooting

Specification