Site Requirements

15

Humidity

The output device requires relative humidity of 55% ±5%.

An industrial steam humidifier can be used to meet specified humidity.

UV Light

Some plates, such as Kodak DITP, are sensitive to UV light. When such plates are

used or when the Lotem 400 / Lotem 400 Quantum output device is directly

connected to a plate stacker, you need an appropriate safe light.

Air Conditioning

Sufficient air conditioning should be present to provide heat dissipation for the

output device,

plus

all additional equipment residing in the system room, and an

additional minimum 25% safety margin. Ensure that the ventilation system can

circulate the entire volume of air in the room 16 times per hour.

The output device requires a constant temperature of 23

×

C ±2

×

C

(73.5

×

F ±3

×

F).

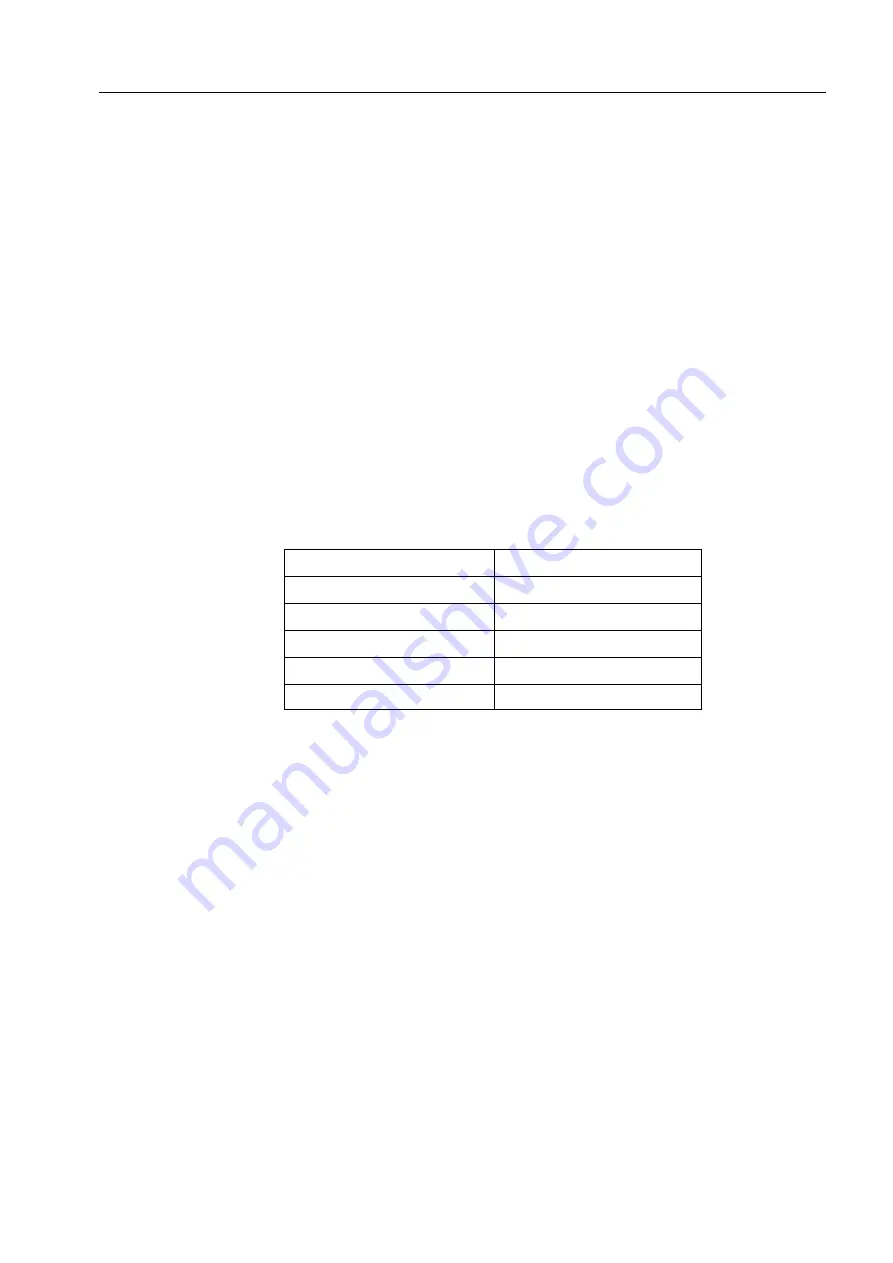

The calculated air conditioning requirements for the output device (in BTU/hour)

are shown in below table.

Please note the following guidelines:

•

The system room should ideally contain both a thermometer and a

hygrometer, permanently mounted in a central location.

•

In addition, it is highly recommended that you have a humidity and

temperature recorder.

Ventilation

No filtration can be 100% efficient (for example, carbon monoxide is not captured

by Creo filters). That is why outdoor air ventilation is required with the debris

removal system. Air exhaust vents (where air is drawn out of the room) should be

located as close to the debris removal cabinet and output device as possible.

The Lotem 400 / Lotem 400 Quantum Family output devices require a minimum

of 1.1 m

3

/min (40 cfm)

1

outdoor air ventilation. This air ventilation prevents the

accumulation of airborne emissions that may be released when certain media are

imaged.

2

Platesetter

12,000-16,000 BTU/hour

Host

2,500 BTU/hour

Debris removal system

4,800 BTU/hour

Other misc.

1,500 BTU/hour

Safety margin (25% of above) 6,250 BTU/hour

Total

27,050-31,050 BTU/hour