SECTION E: PREVENTATIVE MAINTENANCE

As the motor is oil filled, no lubrication or other maintenance is

required, and generally Barnes pumps will give very reliable

service and can be expected to operate for years on normal

sewage pumping without failure. However, as with any

mechanical piece of equipment a preventive maintenance

program is recommended and suggested to include the

following checks:

1) Inspect motor chamber for oil level and contamination.

2) Inspect impeller and body for excessive build-up or

clogging.

3) Inspect seal for wear or leakage and repair as required

4) Clean sump or tank walls and floats where buildup of

debris could be harmful to pump operation.

5) Occasionally start pump manually to make certain it is

operational.

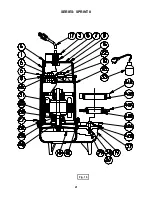

SECTION F: SERVICE AND REPAIR

NOTE:

All item numbers ( ) refer to Figures 15 & 16, for SPRINT

II Series, 17 & 18 for SPRINT III series.

WARNING !

ELECTRICAL POWER TO THE PUMP MOTOR MUST BE

DISCONNECTED AND LOCKED OUT TO PREVENT ANY

DANGEROUS ELECTRICAL HAZARDS OR

PERSONNEL DANGER BEFORE ANY SERVICE WORK

IS DONE TO THE PUMP.

CAUTION:

OPERATING PUMP BUILDS UP HEAT AND PRESSURE;

ALLOW TIME FOR PUMP TO COOL TO ROOM

TEMPERATURE BEFORE HANDLING OR SERVICING.

F-1) Lubrication:

Anytime the pump is removed from operation and at least every

twelve (12) months, the cooling oil in the motor housing (13)

must be checked visually for oil level and contamination.

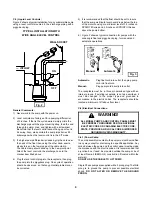

F-1.1) Checking Oil:

To check oil, set unit upright. Remove screws (6) and pump

cover (1), then pipe plug (11). With a flashlight, visually inspect

the oil in the motor housing (14) to make sure it is clean, clear

and that the oil level is above all internal componentry. If oil

appears satisfactory, replace pipe plug. If oil is low or appears

contaminated, test oil as per section F-1.2

F-1.2) Testing Oil:

1.

Place pump on it’s side, remove pipe plug (11) and

drain oil into a clean, dry container.

2.

Check oil for contamination using an oil tester with a

range to 30 kilovolts breakdown.

3.

If oil is found to be clean and uncontaminated

(measures above 15 KV. breakdown), refill the motor

housing as per section F-1.3.

4.

If oil is found to be dirty or contaminated (or measures

below 15KV. breakdown), then the pump must be

carefully inspected for leaks at the shaft seal (30),

cord inlet (5), o-rings (9) & (28), and pipe plug (11)

before refilling with oil. To locate the leak, perform a

pressure test as per section F-1.4. After leak is repaired,

refill with new oil as per section F-1.3.

F-1.3 Replacing Oil in Motor Housing:

Drain all oil from motor housing and dispose of properly. Refill

with 52 ounces of new cooling oil as per Table 1. An air space

must remain in the top of the motor housing to compensate for

air expansion. Set unit upright and fill thru pipe plug (11). Oil

level should be at the top of the motor end bell. Oil level can be

checked by inserting a dipstick in pipe plug hole. Oil level should

be approx. .375" below top of surface.

After filling is completed insert pipe plug (11) and replace pump

cover (1), o-ring (9) and screws (6).

When refilling with oil after servicing the shaft seal (30), a

pressure test as per section F-1.4 should be done.

WARNING !

DO NOT OVERFILL OIL.

OVERFILLING OF MOTOR HOUSING WITH OIL CAN

CREATE EXCESSIVE AND DANGEROUS HYDRAULIC

PRESSURE WHICH CAN DESTROY THE PUMP AND

CREATE A HAZARD. OVERFILLING OIL VOIDS

WARRANTY.

TABLE 1 - COOLING OIL - Dielectric

SUPPLIER

GRADE

BP

Enerpar SE100

Conoco

Pale Paraffin 22

Mobile

D.T.E. Oil Light

G & G Oil

Circulating 22

Imperial Oil

Voltesso-35

Shell Canada

Transformer-10

Texaco

Diala-Oil-AX

F-1.4) Pressure Test:

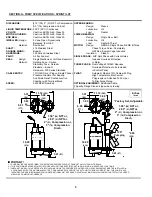

Motor Air Check -

After basic motor assembly is complete and

with seal retaining tool (Fig. 5) installed, motor is ready to be

air checked (impeller can be used in place of seal retaining tool

but it will be difficult to see where leakage, if present, is

occurring in seal area). Apply 6 to 8 PSI air pressure thru pipe

plug (11) hole in top of shell and submerge unit in water. Any

bubbling indicates leakage and must be corrected.

14

Summary of Contents for Barnes SPRINT II Series

Page 13: ...Fig 4 CONNECTION DIAGRAMS USED FOR DETERMINING WINDING RESISTANCE 13 ...

Page 21: ...Fig 15 SERIES SPRINT II 21 ...

Page 22: ...Fig 16 SERIES SPRINT II 22 ...

Page 25: ...SERIES SPRINT III Fig 17 25 ...

Page 26: ...SERIES SPRINT III Fig 18 26 ...

Page 28: ...NOTES 28 ...