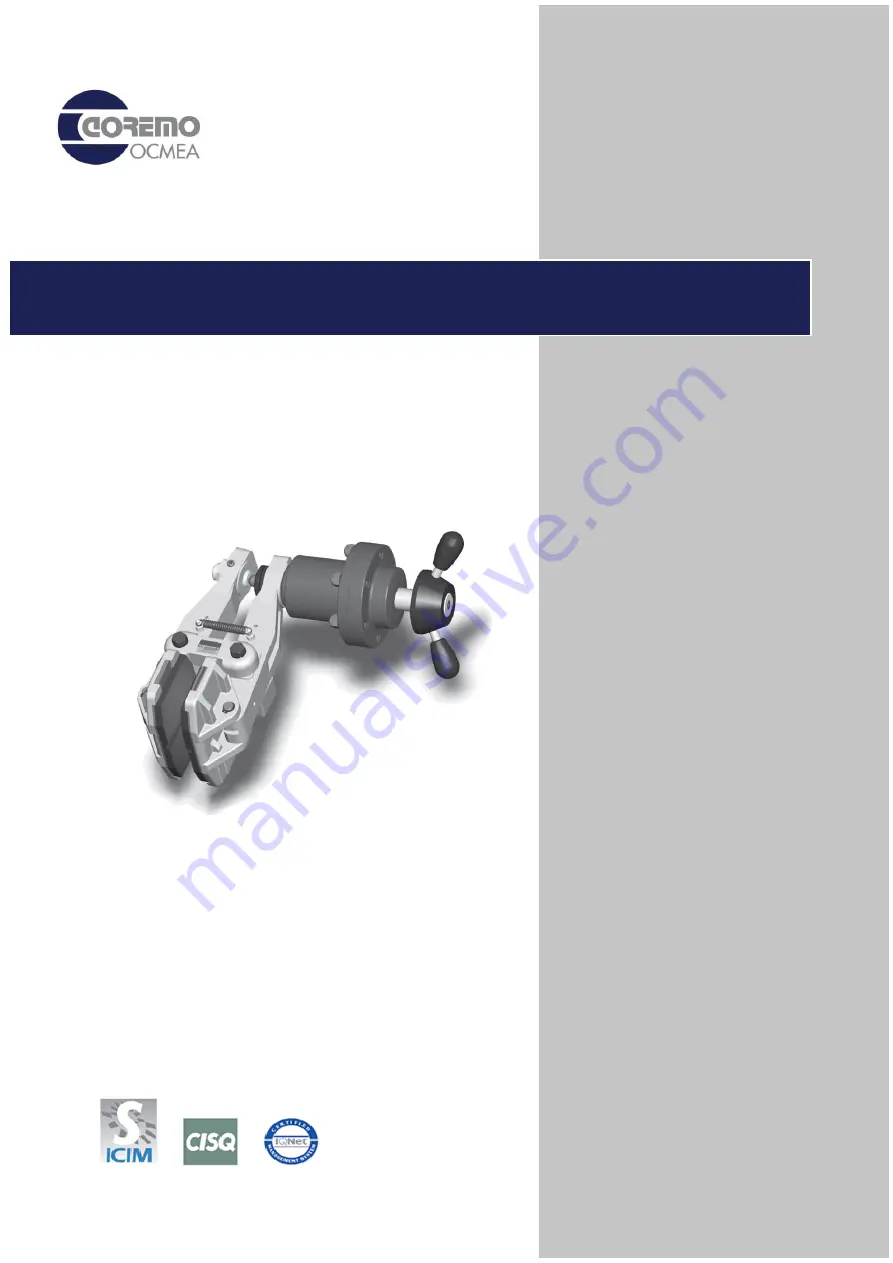

G Manual

Model G-M

COREMO OCMEA S.P.A.

Via Galilei, 12 - 20090 Assago (MI) - Italy

Tel. +39 024880697 Fax +39 024881940

www.coremo.it

[email protected]

User and Maintenance Manual

Translation of the original instructions

EN 130701 REV. 1

ISO 9001 -

Certificate N°0238