Teledyne Continental Motors, Inc.

TM

Maintenance and Adjustments

IOF-550 Permold Series Engine Maintenance Manual

9-15

1 April 2007

9-3.4. Oil Trend Monitoring and Spectrographic Oil Analysis

Spectrographic oil analysis identifies the concentration in parts per million (PPM) of

wear material components in an oil sample collected during an oil change. (Refer to the

section “Collecting an Oil Sample” in this chapter.) This analysis is done, starting with

the first oil change sample, and continues with successive oil changes. The first few

samples establish a baseline; subsequent samples (at least three) taken over time establish

engine wear trends. These trends help determine if wear material is deviating from the

normal baseline. (Establishment of the baseline and ensuing wear trends assume that the

analyses are being done by the same laboratory using the same method of analysis.)

The established baseline and database that develops from the series of spectrographic oil

analyses over time serves as a reference point for determining the engine’s oil trend

analysis as it relates to normal engine wear and deviation thereof.

This analysis helps identify internal engine problems. Deviations from the normal wear

pattern of analysis warrant further investigation and may help detect problems. However,

spectrographic oil analysis, even if done properly, may not provide any indication of

fatigue type failure.

There are two methods of performing spectrographic oil analysis:

•

Atomic absorption (identifies particles smaller than five microns)

•

Atomic emission (identifies particles smaller than ten microns)

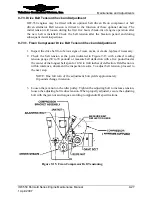

9-3.5. Oil Sample Collection

Generally, the oil sample can be collected at either of the following times:

•

During the oil change procedure, before any new oil is added

•

Between oil changes

The oil sample must be taken after the engine has been operated during a normal flight

profile (including normal cruise and maximum power settings) for at least 30 minutes at

normal temperature as defined Specifications and Operating Limits in Chapter 2.

NOTE: Collect the oil sample within 30 minutes after shutting

down the engine.

Procedure

1.

Clean any dirt or debris from around the oil sump drain plug.

2.

Use the following sample collection devices:

a.

Sampling tube and/or funnel

b.

Sample vial

NOTE: The sampling tube, funnel, and sample vial must be clean

and free of any debris, foreign material, or residue for sample

integrity and accurate analysis.

3.

Collect 1 to 2 ounces (30 to 60 ml) of oil from one of the following sample collection

locations consistently: