CONQUEST REVERSIBLE PLATE COMPACTORS

OPERATOR

’

S MANUAL

- 5 -

•

Tie the machine on vehicle to prevent sliding or tipping over.

•

For long transports, empty the fuel tank completely and close it.

WARNING

Do not lift or hook the plate compactor by the handle.

MAINTENANCE

•

Use original spare parts only.

•

Do not alter the operation devices of plate compactor.

•

Do not turn the engine on without air filter.

WARNING

Modifications in this machine are subject to the expressed approval of Conquest

Attachments. In case of non-observance, Conquest will refuse all liabilities and all

warranties.

•

Do not begin maintenance operations when machine is running or when engine is on.

•

As soon as maintenance and repair jobs have been completed, all safety devices must be properly

reinstalled.

PERIODIC MAINTENANCE

Regular maintenance is required for a good performance of the compactor.

BATTERY

•

Always wear adequate protection for the eyes, face and hands while working near a battery.

•

Do not lean over the batteries while they are being charged or checked.

•

Use caution if using tools or metal conductors, to avoid short circuits and electric arcs.

•

Keep the terminals protected to prevent accidental short circuits.

•

Replace the batteries that have damaged terminals, casing or cover.

•

When charging, place the battery in a ventilated area.

•

To recharge, always use a battery charger with regulated voltage with the limits indicated (see

"Information on recharging" later in this booklet).

•

An overload can lead to the opening of the safety valves with the release of flammable gases, and

damage to the battery.

•

It is not possible to replace the liquid or add water to the Optima® batteries.

•

If the battery becomes very hot or whistles during charging, unplug it immediately.

•

An incomplete recharge can lead to poor performance and reduced autonomy

Summary of Contents for CA5570

Page 18: ...CONQUEST REVERSIBLE PLATE COMPACTORS OPERATOR S MANUAL 18 PUMP...

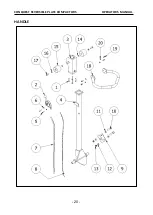

Page 20: ...CONQUEST REVERSIBLE PLATE COMPACTORS OPERATOR S MANUAL 20 HANDLE...

Page 22: ...CONQUEST REVERSIBLE PLATE COMPACTORS OPERATOR S MANUAL 22 EXCITER...

Page 24: ...CONQUEST REVERSIBLE PLATE COMPACTORS OPERATOR S MANUAL 24 BASE PLATE...

Page 26: ...CONQUEST REVERSIBLE PLATE COMPACTORS OPERATOR S MANUAL 26 ROLLBAR...

Page 28: ...CONQUEST REVERSIBLE PLATE COMPACTORS OPERATOR S MANUAL 28 ENGINE SUPPORT...

Page 30: ...CONQUEST REVERSIBLE PLATE COMPACTORS OPERATOR S MANUAL 30 ENGINE SUPPORT...