60

MAINTENANCE

EXTRAORDINARY MAINTENANCE WORK

REPLACING THE SQUEEGEE UNIT RUBBER BLADES

The good condition of the squeegee rubber blades guarantees better

cleaning and drying of the floor, as well as a longer vacuum motor

life.

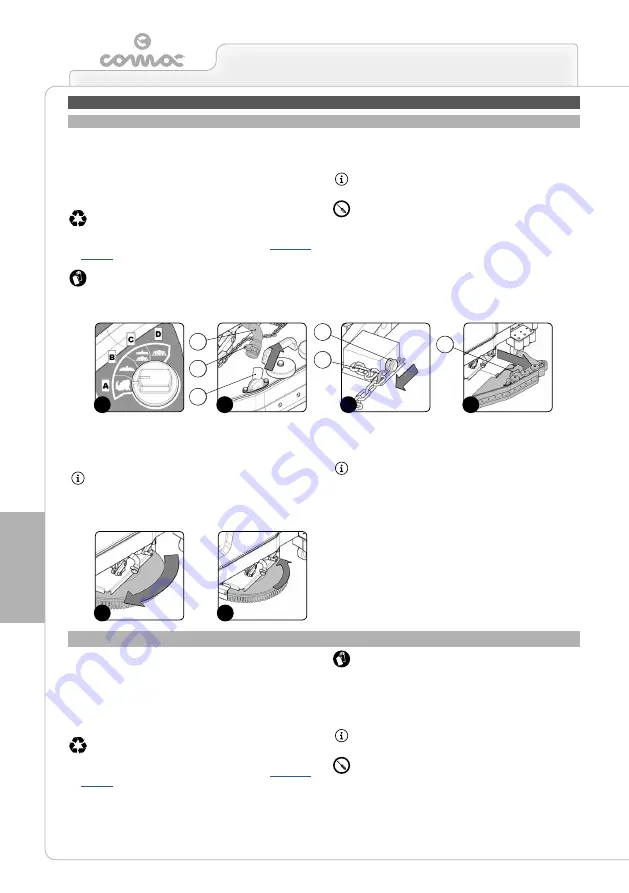

To replace the squeegee rubber blades, proceed as follows:

1. Select the i-drive program “transport” by rotating the knob to

position “A” as shown in (

Fig.1

).

2. Take the machine to the maintenance area.

ATTENTION:

the place designated for this operation must

comply with current environmental protection regulations.

3. Make sure the machine is in a safe condition (read “

ATTENTION:

these operations must be carried out using

protective gloves to avoid any possible contact with the edges

or tips of metal objects.

4. Stand at the back of the machine.

5. Remove the squeegee vacuum tube (1) from the nozzle (2) on

the squeegee unit (

Fig.2

).

ATTENTION

: remember to loosen the screw clamp (3) on

the vacuum tube before inserting it in the nozzle (

Fig.2

).

ATTENTION:

the equipment to be used for this operation is

not supplied with the machine.

6. Remove the knobs (4) from the squeegee unit (

Fig.3

).

7. Remove the squeegee from its support (

Fig.4

).

REPLACING THE BRUSH

The brush's integrity ensures better floor cleaning, as well as a longer

brush motor life span.

To replace the brush, proceed as follows:

1. Select the i-drive program “transport” by rotating the knob to

position “A” as shown in (

Fig.1

).

2. Take the machine to the maintenance area.

ATTENTION:

the place designated for this operation must

comply with current environmental protection regulations.

3. Make sure the machine is in a safe condition (read “

ATTENTION:

these operations must be carried out using

protective gloves to avoid any possible contact with the edges

or tips of metal objects.

4. Stand on the right side of the machine. Disconnect the side

splash guard vacuum tube (1) from the vacuum nozzle (2) on

the splash guard itself (

Fig.2

).

ATTENTION

: remember to loosen the screw clamp (3) on

the vacuum tube before inserting it in the nozzle (

Fig.2

).

ATTENTION

: the equipment to be used for this operation is

not supplied with the machine.

5. Remove the pins (4) that block the rotation pins (5) of the brush

head splash guard (

Fig.3

).

6. Use the relative handle (6) to remove the right-hand splash guard

pre-assembly (

Fig.4

).

7. Rotate the brush clockwise (

Fig.5

) until the three buttons come

out of the slots on the plate. Turn until the button is pushed

towards the outside of the coupling spring and is locked into

place.

ATTENTION

: the picture (

Fig.5

) shows the rotation direction

for releasing the right-hand brush. For the left-hand brush,

turn in the opposite direction.

8. Insert the new brush in its seat on the brush-holder plate, turning

it until the three buttons enter the slots on the plate. Turn until

the pin is pushed towards the coupling spring and is locked into

place.

ATTENTION

: the picture (

Fig.6

) shows the rotation direction

for coupling the right-hand brush. For the left-hand brush,

turn in the opposite direction.

9.

When the right-hand brush has been fitted, reassemble all the

parts and then fit the left-hand one.

1

4

5

6

2

3

1

1

1

1

1

1

2

1

3

4

5

6

Summary of Contents for ULTRA 120 B-G

Page 2: ......

Page 7: ...7 36 72 102 6 9 10 110 107 106 75 5 76 74 58 7 59 7...

Page 9: ...9 103 4 56 31 43 109 15 3 98 22 65 24 108 19 34 35 23 68 44 63 64 99...

Page 10: ...10 2 94 17 101 96 105 69 12 11 18 73 40 97 95 104 42...

Page 68: ...68 NOTES...

Page 69: ...69 NOTES...

Page 70: ...70 NOTES...

Page 71: ......