25

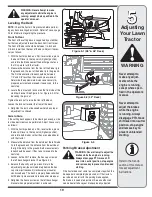

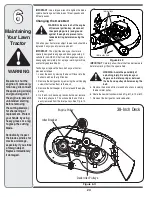

%NGINE0ULLEY

)NCH$ECK

)DLER"RACKET

$ECK)DLER0ULLEYS

Figure 6-12

6

Maintaining

Your Lawn

Tractor

WARNING

Be sure to shut

the engine off,

remove ignition key,

disconnect the spark

plug wire(s) and

ground against the

engine to prevent

unintended starting

before removing the

belt.

Avoid the possibility

of a pinching injury.

Do not place your

fingers on the idler

spring or between the

belt and a pulley while

removing the belt.

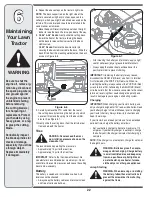

Changing the Lower Deck Belt (46” Decks)

NOTE: Several components must be removed in order to change the tractor’s lower deck belt. See an authorized

Service Dealer to have your lower drive belt replaced or phone Customer Support as instructed on page 2 for informa-

tion on ordering a Service Manual.

Changing the Transmission Drive Belt

NOTE: Several components must be removed and special tools (i.e. air/impact wrench) in order to change the

tractor’s drive belt. See an authorized ervice Dealer to have your drive belt replaced or phone Customer Support as

instructed on page 2 for information on ordering a Service Manual.

Figure 6-13

Deck Idler Pulleys

En

gin

e Pulley

Belt Cover

46-Inch Deck